Opinions on this Monolithic Slab with Interior Edge Insulation Detail

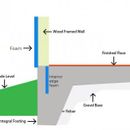

Does the code approve of a monolithic slab with interior (inside the concrete) foam edge insulation? See the attached graphic.

The idea is to be able to deal with termites inexpensively and still have exterior foam and a well insulated moderately priced structure.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

That design would not work well for many reasons, some structural, others with the forming and placement of the insulation. It wouldn't prevent thermal bridging into the wall, and would essentially be stopping no flow of heat anywhere

If you're concerned with termites, solve it a different way -

Change the type of insulation, and move it to the outside, covered with a cement finish of some kind. grade and treat the soil with a pesticide for termites, keeping them out in the first place.

I believe the recommendation, and in some places code, is to leave a small gap for inspection between the top of the insulation around the thickened edge, and the sill plate for the wall. If you see ingress there, you can treat those areas again.

SierraWayfarer,

- As Kyle said, locating the insulation there makes it completely ineffective.

- "Code" is actually whatever code applies where you are. That can be a several. Ours does not have a prescriptive option for thickened slabs and requires a structural engineer to design them.

- How much insulation and where it is best located is heavily dependant on where you are building. That said, there aren't many areas of North America where sub-slab insulation isn't a good idea.

- I would urge you to look at GBA's Detail Library and other sources to get a feel for how this is usually done before you decide to modify the design.

Klye and Malcolm,

Thanks for the replies. What I am trying to do is modify this detail (see attached) for a monolithic slab. Martin Holliday: https://www.finehomebuilding.com/2014/07/09/insulating-a-slab-on-grade. What changes can I make to my detail.

Sierrawayfarer,

GBA also published a blog this week which has another take on these foundations and includes continuous insulation under the footings: https://www.greenbuildingadvisor.com/article/high-performance-raft-slab

Thanks <Malcolm,

I am in zone 3-b, hot dry, Southern New Mexico. That high-performance-raft-slab would be something used in cold climates, right?

Before going too far with your design, you should find out what your code requires as perimeter and sub-slab insulation. That's the starting point. Then what everyone else is doing in that situation, then consider alternatives.

Hi Malcolm,

The design is only in my mind so far. No sub-slab requirement in 3b. Edge is required unless locally excepted for termites. I haven't talked to the local inspector but I have his phone number. I will be building a thermal barrier above code.

Little to no housing construction going on here. Shrinking town of 3000 people but it is peaceful, real estate is cheap, and though in the Southern middle desert (4000 ft.) it is only 50 miles to alpine (7000+). Closest town above 300 people is 40 miles. Not likely to find any green builders close by but I might find somebody who needs work and is willing to listen if I can figure it out. I spent 7 years as a truss-designer so I can read plans.

I read today a GBA member's post where he is attaching rigid foam to traditional 3-coat exterior stucco and then adding another stucco layer above the foam. There are probably several hundred houses in this little town that could benefit from that. There are 10s of 1000s of houses in NM that could benefit. Stucco on a lot of these old houses looks bad but if it hasn't been hit by termites the wood frames are generally good because of the low rain and humidity. I am watching that post...

Sounds idyllic. Good luck with your build!

Sierra,

Shamelessly stealing this figure from the DOE Building Foundation handbook, but it describes exactly what you want to do. Give it a good read over, its full of great ideas.

https://foundationhandbook.ornl.gov/handbook/section4-1.shtml

Hi Kyle,

What is that 'protection shield' that looks like it is glued to the rigid insulation that extends down into the ground? Would it last and look good?

Sierra,

That's a question that doesn't get nearly enough attention in my opinion. Most details leave it as "protection board" or some generic name, without ever specifying what it's supposed to be, do, look like, or attach to the foundation.

Most of the time it is actually an assembly of its own, and often comprised of a cement fiber board (1/2" thick James Hardi backer board or 1/2 USG Durock) plus some type of applied finish such as stucco, acrylic stucco, thin veneer stone or brick, or anything that you really desire that looks nice and is durable. The attachment can vary as well, but concrete fasteners like tapcon perform well. If you're using XPS you can mostly skip the cement board and lathe directly over the insulation for a skim coat of whichever finish you choose.

It can last as long as the structure itself, but like all things, it also requires maintenance. To some degree I would consider any coating or finish you apply here to be sacrificial - it's right where people trim, hit it with lawnmowers, kick their boots, and it gets the most water of anywhere on the building, with exception of the roof. But, it's better to repair that then a section of the footing, should it ever need it.

Hi Kyle,

I posted that detail (above) by Martin Holliday for insulating a slab on grade. I guess it requires three concrete pours; 1st for the footing, 2nd for the notched stemwall, and 3rd for the slab on grade. But our frost line here in zone 3-b in Southern New Mexico probably isn't 6" down. Do you think an engineer might let me get away with only two concrete pours? The first being a combined footing/notched stemwall? Then a second pour of the slab with insulation extending down to the bottom of the first pour and horizontally out below the slab for about 3'? Also, besides allowing me to watch for termites would that work for a thermal break. I attached a crop of Martin's detail.

That notched stem wall can be poured all at once, any concrete crew worth their salt should be able to form that and pour it without issue. They will simply put another board across the top of the form where the thick part of the wall ends, pour around the perimeter, and come back to that section after the concrete just begins to become 'thick'.

I would say that this detail is very good, compared to typical monolithic slab pours. While insulation on the exterior is great, it is not without its drawbacks. This method is easily 4x faster to construct, and cheaper, and easier to maintain than the exterior insulation detail. The only draw back is the thermal bridging between the foundation and the bottom plate. Assuming you're insulating the wall cavities, it's probably not all that big of a deal.

Since you're in a climate zone that rarely, if ever freezes, I wouldn't be as concerned about the durability of the exposed concrete, as if you were in the north, in a wet freezing cycle every year. You can also finish the exterior of this detail, in any way you choose, similar to the other. So in that sense, they are practically indistinguishable to a 3rd party.

Not to nitpick the detail, but I'm certain you'd want gravel and a 10-15 mil membrane in there as well, with the gravel on the compacted soil, insulation, membrane, and then concrete.

Kyle,

Thanks again, you have been a lot of help. I will create a corrected detail showing proposed footing dimensions and "gravel on the compacted soil, insulation, membrane, and then concrete" before it goes to the engineer.

As for the exposed exterior concrete foundation, we have overnight temperature lows into the 20's in mid winter with the absolute low last winter about 15 degrees. We had one snow of about 3 inches that was completely gone within 3 days. Mostly, like all of the year, it is dry. As far as treating the exposed exterior concrete is there some sort of paint or sealer? I would think the paint (or sealer) should stop liquid water but allow vapor to pass for drying. Does that sound reasonable? This would allow me or any future home owner to walk the perimeter of the foundation and look for termite mud-tracks.

I also assume that I should treat the ground beneath and beside of all of the concrete for termites before the concrete is poured.

Sierra,

You're on top of it! A good vapor-open sealer on the concrete would do well here. I have used foundation armor's silane/siloxane sealer with good results. It is expensive, but a little goes a long way, and its worth the added long term durability. It requires the concrete to be cured for at least 28 days, and can be applied with a roller or garden sprayer.

https://www.foundationarmor.com/armor-sx5000-5-gallons

Just as an aside, I agree with Kyle, not discussed enough.

I've said it elsewhere and I'll reiterate here: I did NOT have a good experience with Nudo's Groundbreaker, and will be removing it from my structure, and replacing the XPS with Styro Industries' pre-finished XPS panels.

https://www.buildingscience.com/documents/insights/bsi-059-slab-happy

A good but bad option is to insulate the floor of the slab itself (Fig 2 & 3).

Thanks John,

I guess that is where the detail I modified came from. Joe is really good.

Personally I like option seen in Fig 1 and it has already been mentioned by other above but apparently it's not code approved because a portion of the sill plate overhangs onto the foam. . Strangely enough a GBA contributor used Fig 1 for his house build a couple of years ago. Who knows? This is where a product similar to FOAMGLAS would work.

Definitely ask Joe about that.

Interestingly, Wisconsin, which has their own unique code, has a prescriptive process to overhang sill plates. Figure 1 would be legal here if the bottom plate is a doubled 2x6, and the foam were 1 1/2" thick.