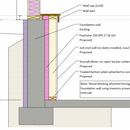

Half-Wall Assembly for Walkout Basement

I have attached a drawing showing proposed wall section for the walls that have foundation exposed. Was hoping to do a half-wall.

There seems to be a code in Minnesota to not penetrate rigid foam when affixing wall. “2. The insulation shall not be penetrated by the placement of utilities, fasteners, or connectors used to install a frame wall with the exception of through penetrations.”

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I think it would be much simpler to make the wall full height.

You can strap out the rigid with either 1x4s or 2x4 on flat. Frame out the wall on top to bring it out flush to this strapping. The extra space can be insulated or left open. You can run the electrical through the wall on top and for the occasional outlet on the bottom hog out the foam a bit and use surface mount device boxes recessed so they are flush with the drywall.

You now have a simple flat surface to drywall and no need for any trim.

Around windows it helps to drop the sill of the interior stud wall about 6" to 8" as it makes the window opening feel much bigger.

Thanks! What would your recommendation be for filling the gap between the existing above ground wall and new interior stud wall if I went with a full height wall? Can I just fill gap with batts?

Nothing wrong with filling the extra gap with insulation, you end up with a pretty high R value wall for not much extra effort. You want to make sure your wall vapor barrier is tied in to the rigid bellow for air barrier continuity. Also don't forget to fire block at the top of the new wall.

Thanks again for your help. I have attached a new picture showing my proposed full wall.

I didn't understand comment about tying vapor barrier for continuity. I was assuming vapor barrier is not needed on the bottom of wall since XPS is used.

As shown in drawing I proposed not filling cavities in wall with extra batts. I'm not sure if that is good, though, from a moisture aspect on upper part of wall.

In most cases the vapor barrier in the house also serves as the main air barrier, you want to make sure this is continuous. You want to tape the vapor barrier on the existing mini walls to the foam bellow. Use a quality sheathing tape (ie Zip/3M/Tyvek) for this connection plus to tape the seams of the rigid. The existing poly plus the interior rigid on the concrete is all the vapor barrier you need, you do not want anything in the new stud wall.

Since you have a layer of exterior insulation as well, your total insulation that handles condensation control is R20. This means means you can fill the stud walls with unfaced batts without issues. You can install batts into the mini wall section as well just make sure these are push right against the vapor barrier. Gaps between drywall and insulation are fine since these spaces are pretty much at room temperature. Your R20 of rigid is already pretty high so I would not loose any sleep if the batts are skipped, the extra bit of energy saved there is minimal.

You need to fire block also the gap between the existing mini wall and the new interior stud wall. The simplest might be to use a wide top plate for the new wall.

Thanks!

Will do regarding the vapor barrier.

Regarding the insulation on lower part of wall. I think Minnesota has a maximum R value on interior of R-11 if R-10 insulation is on the exterior: https://www.northernbuilt.pro/construction-design-below-grade-insulating-new-construction/

I haven't thought too much about fireblocking up to this stage but I think I understand more the reasoning. If I did a wide top plate it would be > 8 inches. Do you think it might be better to install OSB first as fireblock before standing up wall with 2x4 top plate? Or just fill gaps with Roxul or something after standing up wall?

"Minnesota has a maximum R value on interior of R-11 if R-10 insulation is on the exterior"

That is strange. No matter, when it comes bellow grade, your R20 is more than enough anyways. Hard to tell from the picture but if the mini wall is only 2x4 with no exterior rigid, I would put a layer of batts into the upper section of the wall at least.

" install OSB first as fireblock before standing up wall with 2x4 top plate? Or just fill gaps with Roxul "

Either option works just as well. You can also scab some drywall offcut pieces up there after the walls are in place.

I'm a little overwhelmed with choices for sheathing tape in post #5: "Use a quality sheathing tape (ie Zip/3M/Tyvek) for this connection plus to tape the seams of the rigid"

Do you have a recommendation? Would acrylic or butyl be best? I did run across this:

https://www.amazon.com/3M-Construction-Seaming-Tape/dp/B007UUKS50?th=1

That should work for the vapor barrier and any foil faced insulation. Some foam is hard to stick to and might need a different tape, this is good information about the topic:

https://www.finehomebuilding.com/membership/pdf/8169/021234046.pdf