Minisplit sizing and number of minisplit heads for this apartment?

Hello Martin and Dana,

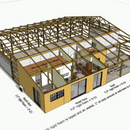

We continue to progress on our project and are about to have the rough electrical started. As a refresher, this is the 700 sq. ft. apartment inside a post-frame construction shop building in climate zone 3.( My last dilemma I needed help with was a question about insulation between studs along with exterior insulation)

I am talking with an HVAC contractor who specializes in Mitsubishi products. I realize you get 20 questions per week exactly like what I am about to ask, and I appreciate the patient help.

Based on the drawings I sent him (the same that are included here), he is recommending a Mitsubishi MXZ 2-ton outdoor unit with three heads of 9000 btu’s each. One would be mounted in the bedroom, one in the living room, and one in the office to the right (south) of the kitchen. Optionally, he said we could go with 2 heads, like a 12000 in the kitchen and a 9000 in the bedroom, and have room to upgrade with a smaller third head in the office if it became necessary.

This seems oversized to me given my insulating and air-sealing efforts. I realize that recommendations are probably not going to be forth-coming or accompanied by a massive disclaimer given I do not have any Manual-J calcs, but… I just want to make sure I’m not being totally taken for a ride here…

(I will post more pics in subsequent posts due to the upload restrictions)

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Here are some more drawings.

I might note that the shadows are accurately geo-located to the hottest time of the year as well as the hottest time of the day. We plan to install awnings over the doors as well as UV-protectant film tint on the window and door lites, but this would probably be a post-move-in project.

Sorry, didn't get the picture attached correctly.

Here is the plan with the loft areas hidden.

Here is with the shop building invisible.

Sorry, trying again..

John,

At the risk of sounding weary, I'm going to explain something that you may have heard before: The first step to designing a heating and cooling system is to perform a Manual J calculation.

Here is a link to an article that you may want to read: Who Can Perform My Load Calculations?

John,

You really need the Manual J. My home has a conventional 2 ton air-source heat pump. But it is 3,200 square feet. Your contractor wants to service 700 square feet with a similar amount of capacity.

You may want to hire an HVAC engineer to calculate the heating and cooling loads. With such a small space, he/she may recommend a conventional ducted system as a more cost-effective approach.

If the ceiling is clear-glass glazing pointing to the sky as in the pics, 2 tons isn't nearly enough! :-)

But seriously, it's unlikely that neither the heating nor cooling load calls for more than 3/4 tons total. The west facing slider on the bedroom could be a cooling-season comfort issue for the "early to bed" types without it's own cooling register or head if not shaded by exterior trees/hills/buildings. But even in a worst case scenario a 9K head there is bonkers, even a half-ton head is likely to be overkill.

The office has no direct sun windows (?), and shouldn't take much to heat or cool.

Is the pole barn roof fully enclosed (insulated or not), or is it more of an open shed surrounding the apartment?

A single appropriately sized mini-duct cassette mounted in the storage loft near the wall to the kitchen would probably work, with registers to the office, bedroom and common living/kitchen area, and maybe to the sleeping loft on the other side of the kitchen (or not, depending on how the load numbers come out.)

How much money are you putting into 700 square feet?

Thank you for the input Dana and Steve. Yes, I realize that a Manual-J is valuable information. Obviously I don't have an official one yet, as stated in the original post, however I did perform my own earlier. The numbers are not out of whack in my opinion - I think it is in the ballpark at least.

Total Btu's cooling: 16933

Sensible Load: 16278

Latent Load: 655

Total Btu's Heating: 17376

After obtaining these figures, I see why the HVAC contractor suggested what he did - A single 1.5 ton outdoor unit couldn't run more than 2 indoor heads of 9000 each. If one was placed in the bedroom, it doesn't seem like the load would be split evenly between them very well. A 9000 + 12000 would seem more capable (in my very inexperienced opinion). But to get that I would have to go up to a larger outdoor unit. That being the case, I think the contractor was thinking that three 9000 heads would distribute the load most evenly and provide the most comfort even with closed doors.

The pole barn roof over the apartment is insulated with rigid poly-iso in-between the rafters to the tune of R-33. Unfortunately there is thermal bridging through the rafters spaced 5' OC. The rest of the barn roof on the south end is uninsulated and the west side is all open. The east wall (the tall side) of our apartment separates us from the enclosed shop which is "insulated" with bubble-foil radiant barrier. We are using that wall as our service wall on the shop side - the plumbing and some of the electrical runs go there. It would also be the perfect spot to run the refrigerant and control lines to a minisplit head. After everything is ran, I plan to install rigid foam across that wall to cover everything.

I was thinking about running a dual-zone wall-mounted system with a 9000 Btu head in the bedroom and a 12000 Btu head mounted up high on the east kitchen wall. Would that provide adequate comfort in the sleeping loft you think? I'm a little put-off by the ducted minisplit systems just because they seem more labor intensive and ugly. (In my case the ducts would be visible in order to stay inside the envelope).

I appreciate the humor about the ceiling being clear glass Dana.... don't tell my wife that's an option or she would be all for it! LOL

@ ANON3: Not sure what your question was implying(?). Hopefully not more than $35k. The HVAC will be the single biggest expense.

>The HVAC will be the single biggest expense.

That's what I thought, get quotes from traditional HVAC guys too, typically mini split installs are rip offs when it comes to installation cost. Double check the equipment cost at acwholesalers so you know the markups...

Those are not credible load numbers for 700 square feet of conditioned space, and no north facing windows, minimal window area on the east & west sides, and zero wind washing on the north and east sides. It will have favorable design temps on those north and east sides too, since the barn will always be above the outdoor daily low temp in winter, below the daily peak daily temp in summer.

The cooling load might be that high if the two south facing sliders were single pane clear glass and were facing west rather than south, or there were no insulation in the ceiling or something, but not with R33 between rafter beams 5' on center.

A 700' house with uninsulated 2x4 walls, R13 in the attic, and single-pane windows on 4 sides might come in at 17K @ 20F for a heat load, but not a reasonably tight insulated house with double-panes. A heat load of 17376 BTU/hr for 700 square feet is 25 BTU/hr per square foot, which is insane at zone 3 type 99% outside design temps, even for a house with 3x as much window area as yours!

Reality is probably going to come in less than 9,000 BTU/hr for a heat load, and MAYBE 9000 BTU/hr for a cooling load. Any decent 9K mini split delivers at least 10,000 BTU/hr of cooling at it's maximum speed (many will deliver 12K or more), and most will put out more than 10,000 BTU/hr @ 17F as well (with a few exceptions- I'm not favorably impressed with the heating performance of the Mitsubishi HMxxNA series, or it's modulation range.)

For reference, my 2x4 framed house has crummier and way more glass area than yours, a less efficient shape (14 corners to the footprint, three dormers), crummier ceiling-R, and 3.5x the square footage of conditions space, and it only comes in around 27,500 BTU/hr @ 20F.

Seriously, run a more careful load calculation. A 9K + 12K two zone solution could even be 3x oversized!

Well, a cheap way to get real numbers is to put in window ACs and see how it performs, it's going to be more accurate than any theoretical calculations.

Okay Dana, thanks for the input which gives me a better baseline to work with.

It won't make that much difference it sounds like, but I think your orientation with my drawings are off. The wall with the 4x6 window and two sliding glass doors is the WEST wall - the most afternoon sun exposure. The north wall has a 5x7 french door. It's the south side of the building that's under the roof overhang. That's why I didn't question the numbers - because 50% of my west wall is glass with no overhangs.

@ ANON3: Thanks for the advice, I'll look into that. Any idea what a reasonable ballpark installation price would be? (I have no idea if you in my geographical area or not, so I apologize if that's impossible to answer). The HVAC contractor I'm communicating with currently has done work for me in the past on a conventional system. He was quite reasonable then.

https://www.acwholesalers.com/installers/find-installer.jsp

Some of them are pretty dogy, but for me $500-$1000 per head for installation is reasonable. The work is only around 6-10 man hours for the first head. You can get mini split installed in China for usd$50 btw...

Thanks for the link... I've been rummaging around on acwholesalers all day and yet it didn't dawn on me to check for installers there.... So...... only three listed within a 50 mile radius of me LOL. They seem a little more pricey than what I expected.... my expectations were exactly what you had suggested.

Yeah, I wish more kids would go into the trades instead of working minimum wage jobs, there's a lot of money to be made out there.

^^^ True that. But what you are suggesting is "work." That's a four-letter word to this generation ;-)

Okay, so looking at ACWholsalers I've discovered something about the head units... say, hypothetically, that I'm still drastically oversized at 9000+12000... I could go with two 6000s, but I've noticed that the 6000 heads are just as expensive as the 9000s! I would literally spend the same amount for a two zone 18000 Btu system as I would for a 12000 Btu system. - Thoughts?

From experience, even 6000 btu would be way oversized for a small room like yours. I think for 700 total square feet, your best bet is a ducted unit so humidity would be controlled.

Put the duct unit in the garage area, then run ducts to the bedroom, sleeping loft, and the main area.

If you can make the room east facing instead of west facing, it'll help a lot too.

Keep in mind that when your load is less than the minimum output of the compressor, you get inefficient short cycling and poor dehumidification.

Yes, my latest question was more about value than it was about capacity. As for example, if you were going to purchase a car and you can get the 400 horsepower model for the same price as the 200 horsepower model, most people would naturally take the larger of the two. I was just curious about the reasons, if any, that would not be a good idea in the case of minisplits. Short cycling and poor dehumidification would definitely be drawbacks.

"As for example, if you were going to purchase a car and you can get the 400 horsepower model for the same price as the 200 horsepower model, most people would naturally take the larger of the two."

Really? Most would?

Unless I was needing to tow my yacht I'd be option for the smaller engine! (Clearly YMMV ) Oversizing an automotive engine has the same (or worse, usually) efficiency implications of oversizing a heat pump. You don't need anything like 400HP to pick up the groceries, drive to/from work, or even take the family on a road trip over the mountains at highway speed.

If I had to argue the other side, I'd suggest that a slightly over sized compressor would see less hours/load and possibly last longer. Or maybe, with the increased number of cycles, it wouldn't (even with the inverter doing slow starts).

I suspect the cycling is harder on it than running more hours. Overcoming the inertia and refrigerant backpressure on a live start while cycling on/off takes more current/power than just modulating along at low speed. And it's thermally cycling the motor windings & refrigerant coils, causing more expansion contraction cycles for more mechanical stresses.

A slightly oversized system is fine, and even improves net efficiency a bit, as long as the minimum modulated output relative to the average load doesn't force it into cycling a lot.

Perhaps my analogy was misplaced given that this is GREEN Building Advisor. But I would still argue that most red-blooded males would prefer a 400 hp car over a 200. In fact, a lot of people go to great lengths to squeeze out a few more HP even in rather pedestrian vehicles, whether they are getting groceries or hurdling down the drag strip. "Gearhead" syndrome is very much regional however, so depending on where someone is from, I can see the comparison being totally lost.

Regardless, I am curious how you tell (on a site like AcWholesalers for example), what the minimum output is? If I understand correctly, provided a compressor can throttle down to at or below the minimum demand, you're good right? Would this be listed as "capacity range" - Btu/h 7,800/20,000 - as an example?

You have to read the spec sheet from the manufacturer's site. But generally it's 1/4th of max, anything lower and they are reducing temperature while doing no dehumidification (and becoming humidifiers basically, I'm looking at you LG)

I would probably use an LG if someone gave it to me for free, and I would spend its short lifespan saving up for a Mitsubishi LOL.

(Based on experience with LG products in the past).

When mini-splits are tested for efficiency, they are also tested for minimum & maximum modulated output at the standard cooling indoor/outdoor temperatures of 95F/80F, but at +47F out/70F in for heating mode. These minimums are listed in the "submittal sheet" the manufacture delivers to be able to label the HSPF & SEER efficiency. Take it from the manufacturer's submittal sheets or other data, not from a second party reseller, which can have erroneous data without them being on the hook for it's accuracy.

A few submittal sheets as examples:

http://www.fujitsugeneral.com/us/resources/pdf/support/downloads/submittal-sheets/12RLS3.pdf

http://www.fujitsugeneral.com/us/resources/pdf/support/downloads/submittal-sheets/12RLFCD.pdf

https://nonul.mylinkdrive.com/files/MSZ-HM12NA-U1_MUZ-HM12NA2-U8_Product_Data_Sheet.pdf

http://meus1.mylinkdrive.com/files/MSZ-FH12NA~MUZ-FH12NA_Submittal.pdf

http://meus1.mylinkdrive.com/files/SLZ-KA12NA-SUZ-KA12NA_Submittal.pdf

The "nominal" or "rated" heating numbers are usually the maximum capacity at +17F, and the efficiency is tested at that modulation level at both +17F and at +47F (where the max capacity is much higher) to be able to model it's seasonal efficiency. But the min/max heating capacity specifications are at +47F.

The "nominal" or "rated" cooling numbers are the output level at which it's SEER efficiency is tested, but usually well below it's maximum capacity at standard test conditions.

I'm both red-blooded and male, and choose to get limbic system override yuks in ways than oversized internal combustion engines in cars. If that's what floats yer boat, take a test drive in a Tesla Model S and set it to "Ludicrous" mode. (Be sure to cinch up yer Depends before putting the pedal to the metal.:-) ) Off the line torque is higher in almost any electric car (even a Nissan Leaf or Chevy Bolt) than most 400 HP gas-burners, but they don't deliver the same satisfying noise & stink. The thrill of 400 HP gas burners is going to be in the same nostalgia realm as the thrill of riding a fast thoroughbred or Arabian in a few short years, a hobby more than anything else.

Thank you for the links Dana.

The Tesla is an amazing car, no doubt. The Rimac One is even better. I just can't get over the lack of noise, which equates to a lack of soul in my book. Saving the environment is much more important than getting kicks on Route 66, but going fast in an electric car is sort of like faking an orgasm to me.... it just doesn't feel genuine LOL. But I digress

I've went over the manual J calcs multiple times. I'm no professional, but I do find this stuff fascinating so I don't mind taking a stab at it just for kicks if nothing else. Can you please tell me if these numbers seem closer? I've read the accompanying instructions and have been as aggressive as the free software I'm using allows, and I can't get it any lower.

Total Btu's cooling: 12413

Sensible load: 11734

Latent load: 679

Total Btu's heating: 19920

In the breakdown it looks like 8637 Btu's for heating are tied up in the uninsulated concrete slab, which has a perimeter of 120 feet. Since the slab continues for several more feet on the south and east sides of the enclosed apartment, would that have any effect? How would I compensate for that in calculations? Anyways, the next biggest offender would be the glass doors (3 sets) = 3918.

Is it normal for the heating Btu's to be so much higher than cooling? It looks like there are minisplit units out there capable of handling the swing, but it just seems odd to me. Thanks

The slab losses are probably higher than reality, but they may be shrunk with edge insulation on the sides where that is possible. Those heating load numbers are still extremely high for an insulated building unless you used -25F instead of +25 as the outside design temperature. Seriously, that's over 28 BTU/hr per square foot, about where a 2x6/R20 building comes in when it's -50F outside (are you in Fairbanks AK?) And they're even higher heating numbers than indicated in response # 10.

What DID you use for outside & inside design temperatures? (It makes a difference- the capacity of the mini-split varies with temperature.)

What do the numbers look like if you double the performance of the walls that are facing inside the barn?

What do the infiltration & ventilation load numbers look like?

Hmmmm.... well this IS a free piece of software at http://www.loadcalc.net . So I'm not expecting pinpoint accuracy, however you raise good questions...

One of the reasons the heating BTUs went up instead of down is because I didn't understand what the program was asking for regarding the slab, therefore my math was off the first time.

I didn't select the design temps. The program asks me what city I'm in and adjusts accordingly.

So:

The Design Indoor Cooling Temp is set to: 75F

Design Outdoor Cooling Temp: 96F

Temp. Difference Cooling: 21F

Indoor Humidity: 50

Grains difference: 35

Design Indoor Heating Temp: 70F

Design Outdoor Heating Temp: 17F

Temp. Difference Heating: 53F

As for the walls, the selections available max out at exactly what I have, which is R6 rigid board insulation totaling R-21.

The infiltration numbers are as follows:

Sensible: 271

Latent: 279

Heating: 1304

I selected "very tight" for the construction quality, and specified the ducts would be (hypothetically) inside the building envelope.

The system recommends a fresh air intake of 28 cfm AFTER I run the calculation. It's designed so that if I input that recommendation in the appropriate field and run the calc again it takes that into account. But this only INCREASES the BTU requirements, so I left it off.