Methods for air sealing the ceiling

Hello,

We are building in a cold climate, zone 7, using ICF walls. Because the walls are ICF, they act as an air barrier, but I’m trying to figure out the best way to air seal the ceiling. Based on what I’ve read on this site, I’m following a few guidelines:

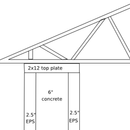

- Ceiling will be flat, using energy heel trusses

- Using blown in cellulose, thinking around R-60

- No recessed lighting (thanks Martin)

We will obviously need J-boxes for ceiling lights along with ceiling fans, and I’d of course like these to penetrate the air barrier as little as possible. There will need to be a couple pipe penetrations for the plumbing stacks.

It seems to me like there are several methods for creating an air barrier, and I’m trying to weigh the pros/cons of each:

- Use a sheet of polyethylene above the drywall. This seems to be the most common method in this area (zone 7), although I’m not sure how well it really ends up sealing in practice because of punctures. How easy is it and what is the best method to seal around all the punctures from connecting the partition walls?

- Do the same thing but use a “newer” membrane product?

- Airtight drywall approach. Requires caulking around J-boxes.

- Use a wiring chase. Attach OSB to the underside of the roof trusses and tape the seams with Siga Wigluv or similar. The OSB is the air barrier. Affix 2x4s which the drywall attaches to and creates a 1.5″ ceiling wiring chase in which you don’t have to worry about air sealing. Would cost more in materials because of the extra layer of OSB and you would lose some headroom.

Any others? I’m looking to figure out what would be the easiest way to have someone do some good air sealing that will last for the long term. Thanks for the advice.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Nick,

By far the most common material to use for a ceiling air barrier is drywall.

You can buy special airtight electrical boxes, or just do a careful job of air sealing ordinary electrical boxes (with a combination of caulk, canned spray foam, or high-quality tape) before installing the insulation.

Thanks Martin. It seems like everyone around here uses polyethylene sheeting but it is just stapled to the top plate so that's not really air sealed. I'm not sure if the inspectors here require the poly or not -- I will need to find out.

I have read some articles on this site and understand that the poly is not recommended for most of the country, but is probably safe in our location, although it is not actually necessary.

So, if it turns out that the poly is required, would you still use airtight drywall as the air barrier and just do the poly like they normally do it? Or would you use the poly as an air barrier by sealing it somehow on the edges?

I have heard of people spray foaming the top of the partition walls in the attic for this reason -- I don't think they have done a blower door afterwards so I'm not really sure if this is an effective way of handling this or not?

Thanks.

Nick,

If you are required to use poly, it isn't hard to do right. The 12" strips over interior walls are placed between the two top plates for mechanical protection and to make the walls walkable when working on the trusses. These strips are lapped with the ceiling poly and either taped or bedded in acoustical sealant.

The disadvantage of using poly is that it precludes drying to the interior, and can cause moisture problems if the house is air conditioned, but as an air sealing strategy it is very effective.

Substitute Contega HF for acoustical sealant if you don't like the nasty oily smell of acoustical sealant.