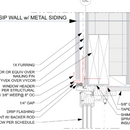

Metal siding — window head flashing detail

OK this keeps resurfacing so I thought I would see what others have come up with. When using metal siding (corrugated or sim.) dealing with the window head always seems to be a bit of a conundrum.Typically I see a piece of “J” flash utilized. But this usually points up, which may conceal the cut of the cladding panel, but consequently also catches water. Seems wrong. I have been trying to come up with an alternative and drew the attached, but surely someone more intelligent than I must have devised a better solution for this issue ?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

The detail says "J channel with 3/8" weep at 8" OC". I assume that 3/8" weep lets the water drain out. Or is the weep what you added?

That J isn't really part of the drainage plan at all, it's just the termination of the siding, so maybe it doesn't matter?

Curious to see what other's say!

Yes, the weep was my "contribution" to the problem. Somewhat labor intensive though....

Just a thought: won't the majority of the water drain out the sides of the J channel? Any remaining water doesn't seem like it's going do much harm. The 2d water in the 2d detail looks trapped, but in 3d, it's not.

Erik,

The J channel gets used at the jambs and sill but not at the head. The same drip flashing that you typically use at the bottom of the wall gets used at the head (and is shown on your drawing). The siding gets held up 1/8" or so above the head flashing which should have end dams formed on both sides.

Thats a long way of saying: Just delete the J channel from your detail and away you go.

Erik,

If the J-channel is required for a clean (attractive) termination at the bottom of the siding, it acts as a gutter. You can use the J-channel if you want, as long as you detail the ends of the J-channel (at the right and the left sides of the J-channel) to handle the water that drips out the ends of the "gutter."

Good corner flashing and side flashing will handle the water. But you have to think the detail through and anticipate the dripping water.

-- Martin Holladay

I've got to disagree about using J channel in an inverted situation. You won't see it in sheet metal installation guides or handbooks for good reason. The flashing profiles used for for metal siding were developed for two purposes: to shed water and to facilitate the installation of the siding.

I don't know of any way to detail or bend the J channel at the head so that the water it sheds at the ends doesn't drain into the wall cavity or behind the siding. Remember, the rear of the profile is installed behind the siding. Inverted flashing will also over time fill with debris - that's where the finish will fail first and rust start.

The trim profiles always includes those with no lips over the siding on corners, bases and window heads because it is difficult, or impossible, to install sheets of siding over an area bounded on four sides by J or similar flashing. How do you get it in? That's also one of the reasons why you see corrugated siding installed vertically much more frequently than horizontally.

If you want the look of a similar profile on all four sides of an opening for aesthetic reasons, use a drip flashing at the head with a similar sized downturn to the J. Thats what the proprietary flashing systems, like those supplied by Hardi for its panels do.

Malcolm,

I bow to your experience with metal siding. And you're right -- these details are easy to screw up.

That said, it's extremely common to see J-channel on vinyl siding jobs above windows. There is a way to do it well, and a way to mess it up. If you are going to use J channel at a window head, you have to think through the flashing details at the window corners, to make sure that you aren't encouraging leaks.

Water gets past the siding; we all know that. The trick is to have the WRB and flashing details behind the siding handle the water so that the water doesn't enter the wall cavity.

-- Martin Holladay

.

Erik and Martin,

This is probably a situation where it would be a good plan to get a few short scraps of J channel and drip edge and mock up the corner on a scrap of plywood. Being from a climate where the consequences of water penetration often proves disastrous has probably made me a bit more sensitive to the detailing of windows than is necessary elsewhere, but I'm stumped as to how this would be a good idea.

Erik,

One small other note: Are you sure you want to detail the head flashing so it is separated by a gap large enough to include a backer-bead? It implies that the caulking will be applied to the underside of the drip edge after installation. Getting that right is hard. Perhaps better is to bed the drip edge in a bead of caulking applied directly to top of the window frame.

I have this J channel detail on our barn and snapped a few pictures to illustrate it and its appearance.

The top J channel hides a few "sins" like where the edge of the head flashing lands on a rib. Also where metal siding panels butt together, in case they aren't perfectly the same length. (I couldn't get an in-focus picture of that.)

In our case using bent down flashing at the top would have resulted in an inconsistent window frame reveal. That however is the detail that shows up in Fabral's installation instructions though.

BTW, these windows are on the west face of our barn that sits up on a hill. They get pounded by the wind and rain, and they do leak. Based on the stains inside on the southern yellow pine lumber, the leaks appear to be only at the sill level. Those sills should probably be reworked someday. (And again it's only a barn...)

This is a good discussion, and I'm sure everyone has a slightly different opinion.

Here's my guiding principle: don't depend on the siding or the J-channel to keep water out of your walls.

To keep water out of your walls, you will be depending on your WRB and the flashing used for your window rough opening.

If you have done a good job installing your WRB and the flashing used for your window rough opening, you can sleep well at night.

That said, you obviously don't want to be directing the water collected by the J-channel into your rough opening.

-- Martin Holladay

Martin,

That's a very sensible summary and I hesitate to add to it, but I think for climates which experience a lot of bulk water related problems the slightly different approach our code takes makes sense.

It identifies "first end second layers of protection". The idea being that the siding layer should be detailed to stop all water intrusion. The second layer, inside the rain screen gap, should also be a complete barrier to any water that gets that far. It's a belt and suspenders approach, which probably only makes sense where driving rain is a real concern, but it works and I've been surprised at how little it adds to the time or cost of the envelope construction.

For posters building here in coastal BC it's also probably worth noting that the flashing being contemplated in this discussion is expressly prohibited by our code.

Here is a reason not to do the J channel head flashing, it focuses water onto specific points on your siding. If you look closely at the pictures I posted yesterday you can see the discoloration/oxidation this caused.

This is probably also why I have the water infiltration issues at the sill level, it's a bulk water problem as Martin alluded to when he said "you obviously don't want to be directing the water collected by the J-channel into your rough opening." You would still need some other kick out detail at those corners.

A standard flashing detail across the top of the window would better disperse the water.

Anyhow I didn't catch this until today when I was splitting firewood and looked over that way. Close up picture attached.

Revisiting this topic and hoping for any new found revelations. I've got a similar situation as described above, with the added complication of a 32+' continuous strip of windows mulled together, so no hope of channeling the water out to the corners. I was hoping to run the j channel around all four sides of the window unit for a consistent aesthetic appearance, and the weep holes seem like a good solution (minus the long term risk build up.). Is the consensus this is just not workable, and to try for a matching drip edge? And try real hard to cut the bottoms of those panels straight?

For a design like yours, I like to have exterior extension jambs that extend beyond the siding, then use a conventional cap flashing and cut the metal siding carefully with a small gap above the cap flashing. It's easier to do with horizontal siding but with vertical siding like your design features you could have the bottom edges sheared at the shop. It's possible to do on site but not easy to do well.

jeffesonm,

Cutting panels consistently is unfortunately part of doing metal cladding or roofing. The exposed edges occur at the bottom of walls, where materials intersect vertically and above windows. Using a metal cutting blade in a circular saw mounted on a shooting board yields good results. You may have to dress the edge with shears a bit.

The other big advantage to not using J trim on the head of the window and base of wall is getting the corrugated panels into place.

Here is a photo of my shed with J trim on the sills and jambs, and a head-flashing.

Greetings from Ireland. Quite a fascinating tour de force of information here on flashings. I’m starting on a timber framed studio building here which will have standard corrugated iron sides and roof. What is exercising me greatly is finding a good flashing detail for the 4 sides (particularly the heads) of door and window openings. The windows will be inset from the sides by about 6”. Also I prefer to have a flashing at the head which will not discharge water dripping onto the metal sill below and rather past it to avoid an annoying drip noise. If anyone can supply me with a suitable drawing / detail I’d be most grateful.

—Harry

Hi Harry,

This is the strategy that I've come up with for my house - using the geometry of the panels as an integrated form of flashing (though there's no reason you couldn't use a bender get the same result with aluminum siding or a thin gauge steel at any point, I think). If someone has a better design idea, I'm all ears.

Neil

Neil,

At the sill: Why not use a wider J channel below your sill and tuck the siding panels into it, rather than having a separate piece of flashing to cover them? You can use the same detail at the jambs.

At the head: The head-flashing should extend out past the trim and cover the J channels at the jambs (which need to be deep enough to cover the ribs of the siding panels). It should have a drip-edge to move the water away from the window, and end-dams to stop water from moving sideways into the wall cavity.

Hi Malcolm,

Good point on the sill J-channel - I hadn't thought of that!

At the head, I was intending to do as you suggest, but didn't really represent it well in the diagram, I think. In addition to the head flash, I am hoping to use the cladding panel ridge from the top side as a bit of double flash that would go over the J-channel before in rejoins the normal lap over the wall beside the window. I've modified the diagram, which hopefully is a little less pixelated than the last.

NeilMac,

That looks good. If you can I'd extend the return on the head-flashing at least an inch or so to make sure water couldn't blow up underneath.

Remember our code here in coastal BC requires that head-flashing to have end dams.