Metal Roof on SIPs: How to prevent battens from rotting?

I am building my own passive solar home using Faswall blocks with a 12″ thick SIP as the roof. I am going to use metal roofing and have been researching the best was to insure a rot-free roof. I am in the mountains of Colorado where we have high winds but not all that much moisture.

The roof is a 2:12 and a 1:12 shed roof fully covered in Grace Ice & Water Shield HT.

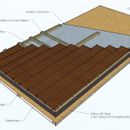

I’ve landed on doing a double batten set up whereby the base layer of furring strips run vertically to the roof pitch to allow for airflow and then a second layer of furring strips to run perpendicular to catch the roofing fasteners – like a #. See attached image

I am concerned about moisture getting under the furring strips with roof contact and rotting those out. Furring strips are also prone to cracking with any kind of fastener so I would probably predrill them all.

I looked at using metal furring channels but those are $1/foot meaning the whole roof would cost $2000 for just the metal channels. Seems a little steep.

Am I over thinking this? Is there valid concern? Are there standard practices for such a setup? Could I simply paint a waterproofing on the furring strip with roof contact (maybe $200 in materials)? Help please!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Using a single batten layer is just fine since there is plenty of air movement to dry the assembly when it gets wet, but it’ll help if you separate the ends of the battens by few inches, to allow for air and moisture flow. You could also notch ¼”x1” grooves or “v” grooves in the horizontal battens. You could install the battens over rubber washers, and something different in Austin, Peter Pfeiffer and Matt Risinger like to install their battens at 45° angle.

When using a double batten layer, you could install the first layer along the framing members and the second layer perpendicular to that. Long ago, on a BSC paper, Joe said it was not needed to use treated lumber for roof battens or rain screens.

Great comments. Thanks for taking the time. This helps me gear up my problem solving engine.

Before you get to committed to the SIP idea you may want to listen to the market it has clearly spoken that this novel idea of SIPs is not the low cost low risk way to build high R value walls and roofs.

I have to ask why such a flat roof in what I assume to be snow country?

Walta

I'm committed. No going back. There's $50k in sip roof panels sitting on my lot. My architect designed it that way so that's how I'm building it. It's been properly engineered for high snow load too.

I would not worry about battens. The only moisture that should make it under your metal roof is from night time condensation which even minimal venting will clear as soon as the sun comes out.

The bigger issue you need to worry about is your SIP. You have to make sure your warm side air barrier is solid otherwise you can end up with SIP rot. I would even go as far as adding in at least one backup warm side air barrier.

I would not cover the outside with standard ice and water as most are vapor barriers. A permeable membrane would be a much better choice. This way any moisture does make it into the seams of the SIP panels, there is a way for this to dry to the space between the roof strapping. Permeable peel and sticks are spendy, you can get similar performance by taping the seams of your SIP and covering the roof with a permeable synthetic roofing underlayment (Hal Breathx, Gaf Deckarmor or Doerken Delta).

For metal roofs, I usually just install the panels over 1x4 horizontal strapping. Make sure your panels are rated for this as some can only be installed over a solid deck.

P.S. Few metal roofs are rated for 1:12, make sure to check install specks. Most are mechanically seamed with mastic sealed ribs. Flashing details are also much more critical as water tends to wick up on low slope. Increasing your slope a bit is simple insurance and saves a lot of install cost.

Grace is code here - no choice. With a sub 3:12, it's code to do the whole roof.

Sounds like a provision for shingled roof.

Post the specific code section about the I&W requirement, there are usually many ways of meeting code.

SIP roofs pretty fragile assemblies, anything that makes it more robust is worth the effort.