Low-Slope Roof Replacement Options

Hello,

I’ve combed through a few articles on low-slope insulation and roofing options, and am now asking a question I am hoping to get some advice on.

– I live in Calgary, in Canada (zone 7a)

– I have a low-slope roof (between 1.5:12 to 2:12 slope) with a 20-year old SBS Modified Bitumen membrane that needs to be replaced.

– I’m currently contemplating between a new SBS or a new metal standing seam.

The roof joists are 2×8, and when I renovated the home in 2014, I added 2x4s on edge running perpendicular to the 2x8s. I put in new batt insulation (R24 for the 2x8s and R12 for the 2x4s), added a poly barrier (I know, I know, lesson learned I should’ve done foam to begin with).

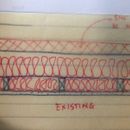

So the assembly is (Exterior to Interior):

– SBS mod bit

– 1/2″ fibreboard

– 1×4 roof deck boards (original to the house built in early 1960s)

– 2×8 roof joists w/ R24 batt

– 2×4 furring w/ R12 batt

– 6 mil Poly Vapour Barrier

– 1/2″ GWB (painted)

The roof does not have a ridge vent, and I am now convinced that a ventilated option is probably off the table. However, if I am going to replace the roof I want to replace the insulation and do it right.

I’ve had numerous proposals from spray foam contractors, but am wondering if anyone has any suggestions for how to establish a non-ventilated roof assembly when installing sprayfoam from the outside, taking into consideration the pesky vapour barrier that will need to remain in place, and potlights which I know Martin Holladay loathes). Here are my current ideas:

1. Remove all the batt and install 2lb closed-cell to the cavity side of the GWB to min R30, and then fill the rest of the cavity with batt?

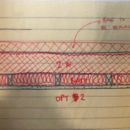

2. Remove the batt in the 2×8, leave the batt in the 2×4, and install 2lb closed-cell in the 2×8 right up to the top (leaving no more than 1/2″ air space between top of foam and underside of sheathing)

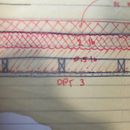

3. Remove all the batt and install 0.5lb foam to the cavity side of the GWB and then 3-4″ of the 2lb foam to fill the 2×8 cavity similar to Option #2.

Any thoughts?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You can't put rigid foam on top of the roof deck boards?

Hi Jon,

I suppose I could add rigid above the insulation but my roof assembly would be prohibitively high and expensive if what I imagine would be required is accurate. I think I’d need 6” of rigid and then the roofing material? How would the roofing tie back to the deck?

How much depends on how much batt insulation you leave in place. But rigid is usually much cheaper per R than spray foam, so for a given total R, it should be less $.

They say long screws to attach sheathing to foam and deck, but not clear to me why glue (similar to SIPs) can't work.

Thanks Jon I just stumbled on the detail library for the unvented vaulted ceilings. Very interesting details...

First, not sure of Canadian codes, but in the US you can't do a metal roof on anything under 3:12 pitch. I would bump up the roof (over roof) and properly insulate.

Hi Paul,

I did look into this. There’s nothing prohibiting sub-3:12 roof slopes from having standing seam, though there does seem to be some debate about whether it would leak depending on the seam profile. Ultimately I’m hoping to do this work once and never again, and with SBS I’d almost certainly be back at it in 15-20 years.

When you say “over roof” do you mean frame it higher with a steeper pitch and then just add more insulation with a proper attic space?

Paul,

Are you sure? I'm not generally an advocate for using metal on low-sloped roofs, but I don't know of any blanket code prohibition on doing so, they just add requirements for sealing the laps.

The BC (and probably the Alberta) code simply says the metal roofing has to be specifically designed for lower slopes.

Some sources say "The minimum slope for lapped, non-soldered seam metal roofs with applied lap sealant shall be one-half unit vertical in 12 units horizontal (4-percent slope)".

This might be prohibitively expensive, but there are rooftop spray foams that can receive an elastomeric coating to become the finished roof. I've only seen it on rare commercial jobs. Saves the trouble of any interior work.

Hi Jason,

That would be very simple. I’m not sure it would be advisable with the vapour barrier remaining in place at the bottom of the assembly?

You can use a commercial roofing system on top of the existing 1x4 roof deck. These systems consist of insulation board (several layers if necessary) that is fastened to the roof deck/framing with long washer-headed screws. The top layer of foam is fleece-faced and the roofing system is adhesively bonded to the fleece facing. These systems come in many flavors of "rubber" including PVC, SBS (or equivalent), EPDM, etc. Some of them do allow adhesive bonding of both the insulation and the roof membrane, but these require far more attention to detail.

Hi Peter,

Thanks for the ideas. Much appreciated.