Vented Low-Slope Roof Assembly

Low-slope roof in Zone 6. Don’t even attempt a vented assembly?

Is a (properly) vented roof without a doghouse, but in a windy area, possible?

My hours of reading (and watching BS*) on this site suggests that a 1.5:12 slope (any slope less than 3:12) will unlikely work as a vented assembly without the inclusion of a doghouse. Am I right in assuming that WITHOUT a doghouse, but despite a) min. of 6” of vent channel between the fill and the roof deck, b) creating ca. 3-4” deep channels above the baffles), c) lots of venting in upper and lower soffits, d) careful attention to air barrier, AND e) depending on the presence of considerable wind …

..that it is still too risky in Z6?

Can the presence of wind and increase vent-depth above the insulation compensate for the low slope?

Details:

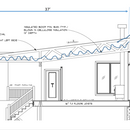

1.5:12 single shed roof (with the exception of a small reverse slope over entry); max span is 37’; open parallel-cord truss design; 18” heal-ht at lowest end; generally windy area – wind is typically westerly, roof slopes upwards from north to south.

The design engineer called for min 13” loose-fill cellulose in the ceiling.

Note: I wasn’t sure if I should establish a new post, or add to any number of others; e.g:

1) https://www.greenbuildingadvisor.com/article/insulating-low-slope-residential-roofs

2) https://www.greenbuildingadvisor.com/article/the-bs-beer-show-roof-venting-when-where-why-and-how#0; runtime mark ca, 1:00.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

m-elo,

You are describing what Joe L. says works in the article you linked to - but minus the mid-span doghouses. I would say that moves it from will work to might work, and I'm not sure variables like the amount of wind can be relied on to compensate.

Roof assemblies come in three varieties. Ones we know work, those we know always experience damage, and huge range in the middle that have varying amounts of risk. Especially in new construction, I try and design risk out. My feeling is there is enough that can go wrong with a house without contributing to that possibility.

Malcolm: inre the Joe L. reference - exactly.

With the deep trusses (ca 18" at the heal, and ca. 24" elsewhere) there will also be a >6" of space above the loose-fill.

But, while I was hoping to get comments to the otherwise, I'm 'guessing' that with 1.5:12, the known issue of too-little convective flow simply outweighs the help of advection from wind (variable as it is) and lower friction from the deeper channels.

I guess an unvented hot roof is in my future.

Thanks for your thoughts.

m_elo,

On the spectrum of the risk in that middle category of roofs, I would put your proposed assembly close to the low end. I wouldn't go as far as Akos to say it will definitely be safe, but it's certainly pretty close.

A big part of my aversion to these marginal assemblies is how they will do over time. Relying on assemblies remaining as air-tight as they are when built is a lot easier with one diligent owner, who understands what is at stake.

I have a bit different perspective. One important function of roof venting is to make sure the dewpoint of the attic space is the same as outside air. Getting airflow in there through convection does help but not the only mechanism. Since the attic space is open to outdoors, you will still get a fair bit of moisture through simply through diffusion.

I'm in the north end of zone 5 with cold winters (or at least it used to be) and hot humid summers. Vented low slope roofs are pretty common and hold up just fine until somebody shotguns the ceiling with pot lights.

If you build a tight ceiling and provide above code vent gap and open area, I would not worry about. When it comes to drying, darker roofs work better than light roofs. Of course if you are in an area with lot of rain and humid shoulder season where everything grows mold, vented low slope would not be the best idea.

If you are looking to do a bit more, about R5 rigid above the roof will raise the temperature of the deck to significantly reduce the chance of condensation. With a vented roof this R5 won't reduce your heat loss which doesn't matter since you have lots of fluffy, it is just there only for condensation.

I'm in dry zone6 (6B)

planning on a black standing-seam metal roof, but..

1) it faces north

2) there is likely snow on the roof in the winter (code is conservative at 85 psf+dead+drift; but you get the point - it snows a bit here).

3) shoulder seasons - not humid per se, but it can snow in October and it can snow in May, so the drying season, while not humid, is not super long.

At 1.5:12 I would be more worried about the metal roof itself. At that slope water flows uphill from capillary action so you can't just lap your joints, all joints need sealant or mastic. That reverse slope section will not be fun to make water tight.

Unless you have a height restriction, why not bump up the slope to 2:12 which gets you into standard snaplock and also avoid any worry about low slope venting.

Overall, in snow country you do want a vented roof, even the unvented ones need a top vent to avoid snow melt.

Akos:

1) thanks for the feedback

2) you seem to have a crystal ball :-) - I do indeed have a height restriction.

I accepted that I would very likely be needing mechanically seamed (standing seam) and sealant.

So your suggestion is: because of the snow-country aspect, that despite the 'attic' venting issues associated with a low slope, it is still better to go with a vented 'attic' (more/less a cathedral ceiling truss cavity in this case) than an unvented attic (?).

Or was it more to the point that with a low slope and unvented attic, while I might have dealt the impact of inside vapor on the underside of the roof decking (by going low-slope), I now have a significant issue of ice dams (and their impact on sheathing from the top-side (and hence I need a vent space immediately underneath the metal roofing)?

In snow country your bigger issues is snow melt and icing, these are the ones you need to deal with first and foremost. That means reaised heel trusses plus lots of insulation, good air sealing and venting bellow the roof. You have all those dealt with already.

The sub par venting performance would be less of a concern for me if building with a solid air tight ceiling especially one tested with a blower door. If no warm house air makes it into the attic space, there is very little venting flow you actually need to keep it dry.

And yes, if you go with an unvented roof, you need to build and vented over-roof. So you are adding a lot of cost and risk as anything other than spray foam is complicated with trusses and complexity as you need to build two roof decks.

The plot thickens.

Or perhaps, my insulation on the deck, or directly under the deck thickens.

Or perhaps I attempt a vented assembly and take on the double-challenge of the sub-par stack effect with the associated enhanced requisite to keep the ceiling 'solidly' air-tight.

I have a few interior walls that need to go up to support the trusses, which makes one of those beautiful, continuous fields of air-barrier on the bottom chord impossible. But I’ve read enough to know that interior walls are not a deal-breaker.

But as is said many times on this site – no matter what approach one takes, it comes down to getting the details right.

I appreciate the feedback.

Prior to posting I think I was completely discounting the ability to do a vented assembly (the almost universal negative opinion elicited at the one-hr mark in the BS* episode was tough: https://www.greenbuildingadvisor.com/article/the-bs-beer-show-roof-venting-when-where-why-and-how#0). But now, its still on the table (all comes down to the contractor and what he is willing to take on or what I’ll have to do myself from 1500 miles away).

"I have a few interior walls that need to go up to support the trusses, which makes one of those beautiful, continuous fields of air-barrier on the bottom chord impossible."

This is not necessarily true. you can install a membrane on top of interior (and exterior) walls prior to truss installation and then use that to tie in your air barrier. If you need uplift prevention, timberloks work well with this assembly.

f_d: thanks. Makes total sense. I live 1500 miles from this build and I think details like this will have to get done by me. But it is a long-term investment not just for my time in the home, but for those who come (decades) after. So whether it is one trip or three, if the vented roof is the route I go, I think you're right that this is worth it. Thanks for adding that detail.

m_elo,

Up here in Canada where poly is still the most common combined interior air/vapour barrier, we sandwich a strip between the two top plates on interior walls during framing. That protects it from damage when you are standing the roof rafters or trusses, and avoids holes from fasteners. Once the roof framing is complete, you cover the ceiling with a membrane, and tape or seal the two together on the side of the top plates.

clever, and certainly a low barrier of effort for my contractor that allows for some flexibility in timing the framing and the air-sealing.

Thanks