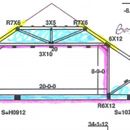

Looking for feedback on insulation design for bonus room with “cut and cobble”

On the attached truss drawing, I used pink highlighter to accent the areas of rigid foam. For the knee walls (technically full height) I was planning on using cut and cobble for the thickness of the 2x6s and then a continuous 4″ layer of EPS on the inside just prior to drywall. Seams would be staggered and taped.

On the bottom of the bottom chord of the truss I was planning on a continuous 2″ layer of EPS.

All attic portions of the truss would be blown cellulose. The bottom 2×12 truss that spans 20′ would be blocked at both ends with rigid foam and then dense packed with Spider.

I know most people on this site tend to frown upon cut and cobble, but I think I can alleviate moisture vapor transmission worries with the continuous interior foam. In addition, the cut and cobble would do a much better job blocking air movement from the “attic” as opposed to dense pack cellulose or high density batts. Since there is no sheathing on the backside of the knee wall, shouldn’t the wall have the ability to dry slowly in both directions?

In a somewhat unrelated question, do you know how insulation contractors would fill the top portion of the attic? If I install the rigid foam before they come, they would be working blind. I thought maybe insulweb on the ceiling and also at the top of the insulation and they could blow it between the insulweb? Might be very tricky to get the insulweb installed on top…..Thoughts?

.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Drawing of truss with insulation layout.

Forgot to mention, I was not planning on an additional vapor barrier. I was going to use the foam as an interior vapor retarder.

This is for climate zone 6 construction.

Rick,

I think that you need a continuous material on the attic side of your kneewalls. Otherwise, it's going to be hard to properly position your first pieces of cut-and-cobble insulation -- and air leaks are far more likely.

The best place to install a continuous layer of rigid foam (to act as a thermal break) is on the attic side of the kneewalls, not the interior side. If for some reason you don't want to do that, at least install some drywall on the attic side of these walls.

I can think of several ways that a cellulose contractor might insulate above the ceiling of this room, but (since I've never done it) I won't speculate. I would have a conference with the cellulose installer if I were you, and ask for advice.

I'm guessing that some GBA readers will also chime in with advice on this point.

Thanks. This might be simpler to engineer once the trusses are up. I thought the diagonal cross brace to the knee wall would complicate the installation of continuous foam on the attic side of the wall, Also the interface of the knee wall and baffle could be dicey to air seal.

From purely an installation standpoint, installing the sheets from the inside is less complicated. The only cuts necessary would be be around outlet boxes. Maybe a few furring strips tacked to the backside of the knee wall would work to hold the foam in place until the sealant is cured?

I know you prefer to see foam on the exterior side of the wall to reduce thermal bridging, but isn't interior placement accomplishing the same thing? Granted the studs would be colder in the winter, but the heat loss would be the same?

You're probably seen a million more attics than I have, but I haven't seen rotted rafters from hot/cold attic cycles.

Your knowledge is appreciated.