Loads and Deflection on XPS Insulated Interior Footings

We’re building a single-story, slab on grade house out in rural Washington State. Very heavy snow loads at 134 psf. Shed roof uses large exposed Glulam Beams often on bearing posts. The foundation consists of a traditional 2’ft deep stemwall on footing around the perimeter of the building, resting on earth. However, the 4″ finish-floor slab is insulated by 4″ of XPS foam below. This XPS is rated at 40psi. The building has a few interior footings. The architect and structural engineer have created detail drawings that show how to insulate those using the 40psi XPS. However they’re having concerns that the loads on the interior footings are greater than the surrounding slab and that leads to cracking.

They’ve outlined 4 ideas:

1. don’t insulate under the footings

Last image is a house plan with footings in blue.

My research on GBA has led to confidence in XPS in compression, but questions about deflection. My structural engineer has not dealt with this specific foam/load issue before. Does anyone have experience here?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Here is a document from Dupont, see footnote 2 in the chart for suggested design safety factors. If it were me I would go with option 2 and do a two pour.

https://www.dupont.com/content/dam/Dupont2.0/Products/Performance-Building-Solutions/literature/179-04061.pdf

Thank you, I will send this along to the structural engineer.

Deleted

I generally use your option 3. If the load is heavy, I often insulate between the footing and the slab, rather than under the slab. Or if energy goals are somewhat flexible, sometimes I don't insulate pad footings at all, though I prefer to when reasonably possible.

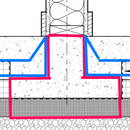

Thanks Michael, I have my options and images a bit mixed up. Are you saying #3, the image below is what you’d generally use? blue=foam, magenta=footing

Yes, although I don't think you need to run the foam up to the surface. Here's a detail from a recent project of mine.

Thanks Michael, this seems like a great solution. I like that it eliminates the tapered edges of foam. Is there a reason the foam has a 2" jog around the footing (where the red arrow is pointing)?

That was to keep the bottom of the footing level with the rest of the sub-slab prep. There is very little heat loss through a pad footing in the middle of a building so having a thermal break is more important than keeping consistent R-values throughout.

For what it’s worth, this is what I would suggest also, the photo order got me mixed up with your description.

why not go to 60PSI XPS? yield would be 8,640 -- right around design values for compacted stone i think. cost is probably a third more, but you aren't talking about a huge quantity of material.

you might consider posting your detail at the stem-walls. if the basement is living space and the slab is not thermally isolated from the walls sitting on earth, then the walls will be a heat sink. i don't have experience with how well those cork expansion boards work to prevent lateral heat transfer.

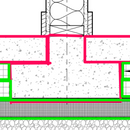

After speaking with my builder, there's concern that doing a two-pour solution for the interior footings creates a slab with lots of inside corners (ie. crack potential), due to the slab going around each footing. He suggests doing a monopour slab without insulating the bottom of the deeper footing areas. Like the image shown here.

My architect has said the we could also potentially eliminate the lower (green) layer of XPS too. Is there enough insulative value here to warrant keeping this lower layer of XPS?

I’ll be laying Stegohome as the vapor barrier over the foam, and I think this lower XPS layer may be useful in creating a clean form to wrap and tape. Unsure how a builder would form this slab-footer without forms.

Penetrations are more prone to cracking. There are ways to mitigate that and good reasons for the way I do it, but if you and your builder want to do a mono-pour that's your call.

40 psi XPS is typically R-1/in when new and will gradually drop to somewhere around R-4.3/in over time. Depending on your location, energy goals and code requirements, you may be ok with less than 4". I don't use XPS because of its high global warming potential, but I do use EPS which has somewhat lower emissions. I'm in climate zone 6 and generally design above code minimums, up to Passive House performance, and usually have at least R-16 under a slab, and wouldn't want less on a new build.

For what it's worth, when I have done mono-pours with integral footings, my engineers have had us slope the sides of the footing and include plenty of rebar, both of which mitigate cracking.

Thanks Michael, I'm sure your detail is sound. I'm trying to balance my builders experience with some of the house's high performance details. The tapered integral footing makes sense. Would like to get your thoughts on whether it's worth including the second (green in drawing) layer of XPS around the integral footings.

FWIW, I found recycled XPS from resources here on GBA (yay!)

Oh I see, sorry I misunderstood what you meant about the added green foam. It would slow heat loss a bit and shouldn't hurt anything. Nice find on the XPS!