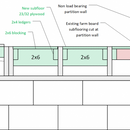

Ledgers and blocking for lowered subfloor in shower

We are remodeling a small master bath climate zone 5A (Ohio). We are planning a lowered subfloor for a Kerdi curb-less shower.

The existing subfloor is 3/4″ farm boards. We will be cutting them out and installing a lowered subfloor in the shower area, so that the new subfloor is even with the top of the joists (2x10s).

We are planning on using 2×4 ledgers and 2×6 blocking at the ends per Kerdi’s recommendation (probably one midway through the shower as well). However, one shower wall is midway between the joists (not load bearing) and has a 4″ HVAC duct in the joist cavity directly underneath. Therefore we can’t fit a 2×6, but we can fit a 2×4. The attached diagram shows the proposed 2×4 in red.

Normal span tables don’t cover this. Using an online calculator and increasing the load due to the weight of the wall (which will be tiled) I still was able to get deflection limits of L/600 for these short spans using 2x4s.

Comments from a code or building science perspective, or anyone who has done this before would be greatly appreciated. Thanks in advance.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Too much detail? Not enough detail? Am I crazy?

amainiii,

I think you would be better with a continuous sub-floor.

If it were me, I would cut down the floor joists by 3/4" to accommodate the new plywood, and if necessary beef them up by sistering a 2"x8" to one side - if that was necessary to limit deflection.

Structurally I think a 2x4 is fine for that situation. But I agree with Malcolm. I'm actually about to start a very similar project at my house, and I'll cut the joists out completely so I can reframe the floor with enough room for a solid, continuous subfloor and a slope. The IRC requires the shower floor to slope between 1/4" and 1/2" per foot to the drain, and the waterproof membrane on the shower floor should be sloped, not directly on the subfloor, which means you need to build a slope or use Schluter's presloped pans.

Thank you. I appreciate your confirming the 2x4 blocking would suffice to support that non load bearing wall.

Regarding the height...

We are using the Schluter KSLT 1220 S pre-sloped 48" square pans cut down to fit into the roughly 41" square alcove. With this small shower, the slope doesn't amount to much (<1"). The recessed subfloor with the KSLT 1220 S set in thinset comes to the same height as the rest of the bathroom covered in 23/32" plywood on top of the farm boards, thinset and Ditra XL uncoupling membrane. The Kerdi installer and the tile installer (two separate subs) said this was fine for a curb less shower.

In a large curb-less shower with Kerdi's largest prefabricated substrate (38x76), the joists have to be cut down at least 9/16" for recessed subfloors, or 1 5/8 for a continuous subfloor. If that were the case, the continuous subfloor is the clear choice.

My going with the ledger approach is due to a combination of issues. This shower is over a concrete wall with sill plate, lapped joists and some mechanicals with limited access due to finished ceilings below. Also, the fiddly work is adding blocking to support the cut farm boards at the edge with ledgers for the recessed subfloor, which would be needed even if with a continuous subfloor.

Thanks again, for alleviating my anxiety about the 2x4 blocking.

There’s a product called rapid recess out there that is approved for lowering your subfloor just fyi. Used it many times for walk in showers.

Also there are companies who will custom make your foam shower pans with a specific starting perimeter height and slope if the kerdi ones don’t work well for your setup.

Rapid recess looks like a great time saver. Thanks for the tip. I checked out "Built with Foam" as one of the custom foam shower pan providers and it looks like a great solution too. In this situation, the problem is not the ledgers for the lowered subfloor but having to add blocking to support the cut farm boards (which support the adjacent finished floors). Thanks!

Seems to me what you have drawn is a jigsaw puzzle and not the proper base for a tile floor. My guess is if you build it you will have problems with cracking tiles and leaks.

Walta

I didn't show the rest of the details for the base, as I was concerned about the blocking needed to support the cut farm boards (which support the adjacent finished floors). The core question was whether 2x4 blocking would be sufficient.

For the preparation of the shower floor, we are following the procedures recommended by Schluter. Here is the video:

https://www.youtube.com/watch?v=OexDcwZKvkc

amainiii,

I think what Walta is getting at is that without a continuous sub-floor to help distribute loads, each joist acts independently, and you might get differential movement, which could cause cracks in the shower base.

Malcolm,

Thanks for pointing that out. I missed it.

In the above video, Kerdi shows 2x6 blocking between the joists which would tie the joists together and reduce their independent movement. We had already planned to do that. Current code requires blocking at lapped joists anyway. We will be blocking at both ends and in the middle.

If the joists were not lapped directly under the shower, and I had good access from below, I would definitely do a continuous subfloor with 8" sistering as you suggested above. The joists are near the limit of the span tables and there is some detectable bounce in the master bedroom, so I'd be reluctant to cut the joists down without sistering.

The block wall directly underneath and the lapped joists present a challenge. But it also means the shower is sitting directly on top of the 2x8 sill plate. That should mean the joists are less likely to move independently. If the shower were midspan in the joists, I think I'd have to do a continuous subfloor and sister to get the stiffness.

Makes sense. Good luck with the reno.