Is sheathing necessary? Detached garage

Designing a new detached garage, trying to determine the assemblies and overall strategy. Hoping for it to be partially or fully insulated/conditioned to use as a shop and hobby space.

A cost saving strategy was suggested, involving skipping sheathing and instead using Mento + membrane and wood let in bracing. Is this risky, is it going to fall apart?

It seems like with anything there are so many different approaches to take. I am trying to come up with the most cost effective design for the garage that will allow us to keep the interior reasonably comfortable year round when in use. It would be nice to have the whole thing insulated so it can be open-concept and flexible, but I am also considering partially insulating it at one and and somehow partitioning the garage in half to divide vehicle space from a hobby space.

Lots more info on my very long post here: https://www.greenbuildingadvisor.com/question/designing-a-pretty-good-homestead-outbuilding-detached-garage

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Izzza,

It isn't risky from a moisture perspective as the sheathing is often the most vulnerable part of wall assemblies. You just need to replace two things sheathing gave you.

The first is structural - both shear so it doesn't fall over, and the continuity from foundation to the top-plate so your roof doesn't blow off. Bracing will deal with the first, except at the doors where you will need a shear-wall. For continuity, you will need mechanical connections - usually Simpsons connectors.

Sheathing also gives you a continuous exterior surface to keep out pests. Without it you need to carefully detail the cladding and strapping to avoid gaps that may let them in.

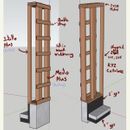

Here is a metal working shop with no sheathing I built two summers ago. You can see the bracing through the open door.

Just to be clear without sheeting you will need diagonal bracing let in or not.

They sell steel bracing the sets in a ½ inch diagonal saw kerf quick, cheap and easy.

The drawing seems to show the interior finished with plywood is that correct?

Walta

Thanks Malcolm, Walta.

My rough rendering shows what appears to be very fancy birch plywood, I just picked a nice looking material so I could do a quick visual that was semi realistic. We like the idea of interior plywood as it would be versatile and durable, also adding rigidity to the structure. I don’t know if drywall would do much for the structural support, apparently it’s cheaper but I can’t see how because the taping and mudding is a lot of work.

Seems like the sheathing-less structure can be figured out then with either diagonal wood bracing or steel. The pest issue is an interesting one! We are in a high risk area I’d say - surrounded by forest and fields, soon with lots of garden - I imagine rodents will be abundant.

We are planning to do vertical steel similar to your photo Malcolm. Seems better than some other types for rodent prevention. I am assuming the high risk area is around the bottom? On the house we have a steel ventilated strip at the bottom, I think this would be pretty good keeping rodents out but the holes seem so big that I imagine bugs could easily get in. Can’t say I know much about this topic, now I must learn.

I suppose it is a separate question but what is a good way to prevent pests in this type of assembly?

" I don’t know if drywall would do much for the structural support, apparently it’s cheaper but I can’t see how because the taping and mudding is a lot of work."

If you hire someone who does it every day they do it amazingly cheaply. Like in an afternoon they do as much as a typical DIY-er does in a lifetime.

But does it hold up very well in garages? I feel like I have a bias against it because I don’t often see it, but maybe it is because people don’t want to spend money finishing a garage rather than drywall being a bad material in there.

You’re talking about $1000 worth of plywood for a 40x30’ structure that gives you a substantially stronger building and less headache detailing. It is not worth it. Also it will be very challenging to get the required bracing on walls with garage doors if you use LIB. The adjustment factors are also substantially larger for let in bracing. Also this $1000 will be offset by the cost of mento.

+1

Sheeting plus cheap house wrap. Much better value and easier to pest proof.