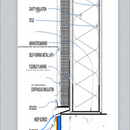

Is my Stucco Wall Detail Okay?

There’s not a lot of information regarding a proper stucco wall detail build up. This is what I have gathered as the right approach, but want to make sure it is here. I’m trying to comply with 2021 IECC that my state is moving to. Zone 5B.

My main question is what type of rigid foam should I be using?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You have no rainscreen effect here. That may not be critical but it's my strong personal preference. To achieve it with stucco I make the outer face of the insulation the drainage plan, rather than the outer face of the wall sheathing, as you have done. I then use either furring or PPE mesh to separate the stucco assembly from the insulation. This creates a proper ventilated space between the back of the stucco assembly and the drainage plane.

With the assembly you have you will be needing insulation that has capacity for drainage between it and the WRB. Insulfoam makes an EPS panel for that.

https://www.insulfoam.com/foundation-insulation-drainage-board/

It's got integral grooves in the back face.

Thank you for the feedback. I did a lot of back and forth on the drainage plane, I'm in a very dry climate (less than 20"), tons of stucco homes in my area with just two layers of grade D paper without issue.

That makes sense why this drawing originally said "Continuous Insulation with Drainage Channels". Without a rain screen or these drainage channels, where would the water go? Would it not just work it's way out the weep screed?

We don't have all the available building materials options here, so I'm trying to stick to as much standard stuff as possible. Maybe furring strips is the way to go.

Does the furred metal lath not create a drainage plane?

The cement in stucco has a tendency to bond to the surface it's applied against. The lath is just there to limit the width of the inevitable hairline cracks that will develop as the stucco cures and shrinks.

In the old days the stucco would be applied against a single layer of building paper, which was supposed to act as a drainage plane. But after lots of failures it was found that the problem was that the stucco would bond tight to the paper, keeping it fully saturated after a rain, with the moisture then working its way into the wall sheathing and framing. The solution was to require TWO layers of building paper. This way the stucco could bond to the outer layer but the inner layer would be undamaged.

Now there are companies selling paper backed lath and double layered paper backed lath. These systems satisfy the code requirement for creating a break between the stucco and the drainage plane. But they do not create a vented rain screen application.

https://stonetooling.com/k-lath-stucco-rite-double-paper-lath-28-x-102/

https://www.clarkdietrich.com/products/paper-backed-lath

If you want a rainscreen, or if your local code requires a rainscreen you need a more substantial gap. Of course, there are companies manufacturing systems for that as well. Or you can create your own by using stock products.

Dorken has its "Delta-Dry"

https://www.dorken.com/en/our-products/products/commercial/delta-dry-stucco-stone.php

To create your own you would first install your WRB. Then you'd need to create a gap. This could be as simple as vertical furring strips, something like 1/2" strips cut from plywood, or 1x4 boards. Then attach the paper-backed lath to the furring. The challenge is to keep the lath from deflecting between the furring strips as you apply the wet stucco. You need a sturdier metal lath than the usual. A way around that is to use a PPE mesh product like this one from Clark-Dietrich.

https://www.clarkdietrich.com/products/e-screen-drainage-mat

There are quite a few manufacturers making a wide range of products to solve these problems. The key is to have a definite separation between your drainage plane (your WRB) and the backing for your stucco. Then you have to decide whether you need to go to the next step of providing and actual rainscreen.

Thank you for all the details. What I'm trying to understand is in this wall detail, if the stucco bonds to the CI, "who cares"? Some water would come down the face of the CI, other water may go through, but when it hits the zip sheating, will it not run down and out the bottom? Does zip sheating require a second layer when doing stucco? Even if there's CI on top? Again, I'm in a very low rain area, rainscreens are not that common and you major issues aren't reported.

Interesting. If using furring strips over the foam, how do you prevent the possibility of the stucco flexing and cracking in between strips? Could you put the WRB over sheathing, then strips, then foam, then stucco? Thanks

Good question. The problem isn't so much flexing and cracking after it has hardened. The problem is more with installation, with the wire mesh flexing when the stucco is being applied. One solution is to use a heavier wire mesh. There are some meshes that are designed to span up to 24" and can even be used overhead against open framing.

Clark Dietrich makes one called 3/8" Rib Lath.

https://www.clarkdietrich.com/products/3-8-rib-lath

Another approach that sidesteps the problem is to use a drainage mesh that covers the whole surface of the wall instead of using furring strips.

Here's an example.

https://www.stucoflex.com/rainscreen_drainage_mats.html

As to your suggestion, yes, I think that layering can be done but I've never done it. That's rather like the typical EIFS installation. The stucco on the foam might even be just a single coat. You can also get foam with drainage grooves in the back so that no furring is needed at all.

Here's an example.

https://brickit.com/products/product-details/drainage-foam-insulation?srsltid=AfmBOoqVIRzY-L38vO3Q1Svt_F8-2rTZ_uCTXxoWK-95bzeAD-Lked2o

Super helpful, thank you.