Is caulking the best option to air seal a sill plate on a remodel?

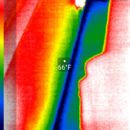

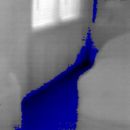

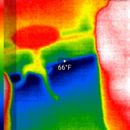

I had a suspicion that the sill plates hadn’t been sealed (the house was built in the 70s) and after breaking out the thermal camera it’s pretty obvious.

My question is how do you attempt to air seal something like this after the fact? It’s brick on the exterior so the only feasible access is on the interior. I personally never have been impressed with the small bead of foam people spray at the sill plate to slab connection, so I was contemplating removing the baseboards and running a bead of some form of polyurethane caulking.

Is there a better way to approach this in an existing structure?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Aston01,

Caulking will work fine. On new construction you want something flexible to deal with framing shrinkage, but that shouldn't be a problem with a 1970s house. Before replacing the baseboards I'd check the progress with your thermal camera again. You may find some of the air is entering from between the bottom of the drywall and the plate. if so, using tape to cover the whole gap might be easier than caulking.

My go-to caulking for air sealing is greenglue sealant (not the compound, the one in red and black tubes). Water based, stick well and stays flexible.

Lot of times when you pull back the baseboard, you can find that the gaps are pretty big. Canned foam is the easier way to fill the big gaps.

Whichever route you go, make sure to clean the area first. With a lot of air leakage there will be a lot of very fine dust and no sealant sticks well to those surfaces.

I have a late 70's home in Central texas, build slab on grade. Untreated sill plate on very poorly floated slab. When I resided, I used polywall blue to seal the sill to the slab and then wrapped the liquid flash over the edge of the sill plate. I then used zip liquid flash to seal the sheathing to the slab as well.

Caulk for small gaps and seams (I like polyurethane caulks), canned foam for larger gaps and voids. I've found canned foam in the gun with the plastic tips (which provide a narrow point) is especially useful for "injection filling" larger gaps I find during remodel work.

Don't use canned foam unless you can get it INSIDE a gap. If the foam is only stuck on the surface, it will not really seal and will fall off and fail in a short period of time. Use caulk for smaller gaps that you can't internally fill with canned foam.

Bill