Interpreting load calculations for minisplits

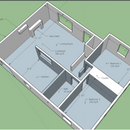

Evening Folks: I live in Seatte WA. 1945 house one story with basement. Last year I had insulation blown into the walls prior to residing with Hardie board. I also had 14 inches of insulation blown in to attic after going through asbestos remediation. The windows had been replaced before and though I don’t know the U factor, I suspect they are pretty average and have chosen not to replace at this time. I’m in the midst of a remodel including basement. Not happy with the gas furnace zoning and not having AC, I chose to pull out the furnace and duct work and move to a mini-split system. I received the attached short form load calculations from one estimate. I’ve also attached the general layout illustrations of the first floor and basement. I have a couple of questions. As I read this form, I presume the Htg Load and Clg Load numbers indicate BTU requirements for any system servicing the respective rooms. If I look at the total first floor it would indicate 12734 total btu’s for the first floor (Bedroom 1, Bedroom 2, Bathroom, Living & Kitchen). To me this says I need about 13000 BTU’s across the first floor (about 800 sqt ft total). Correct? Related, the first floor is an open Living/Dining Kitchen area with an open approach to the bedrooms and bath. My current plan is to locate a wall mount near the fireplace facing toward the bedrooms (Fireplace will be getting a gas insert – it’ll have heat but of course its mostly for ambience — faux bearskin rug to come later). Downstairs I have two adjacent bedrooms and a bath. Total among the three rooms and hallway is 9901 btu. The basement has about 3 ft above ground. The walls will be insulated with R10 solid foam. Though it’s not measured, I am looking to finish the garage — insulated with a tight carriage door to make it multi use. Total sq ft about 270. Based on the information I’ve read on this site, the quotes I receive seem to be way over kill. From my own research, I’m looking toward a three head Daikin with a 12k upstairs, 9k in basement bedrooms areas and 7k in garage/multi room. Compressor is 24k. Another option would be to go with 36k compressor and 15, 12, 7 inside. So am I interpreting the data correct? And given experience with you all, are either of the head size distributions more appropriate for greatest efficiency. Thanks for your input Carlo

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Carlo,

Q. "As I read this form, I presume the Htg Load and Clg Load numbers indicate BTU requirements for any system servicing the respective rooms."

A. Actually, the unit used for heating and cooling loads is BTU/h, not BTU. For your house, this report gives a total heating load of 22,635 BTU/h, and a total cooling load of 13,915 BTU/h.

Are these calculations accurate? It's hard to say. For more information on this topic, see "Who Can Perform My Load Calculations?"

Assuming the heat loss/gain calculations are correct, we still don't have enough information to assist you. Daikin makes a lot of different minisplit units. Without knowing the model numbers, we can't check the heating capacity or cooling capacity at your design temperatures to determine if the units are correct. The numbers displayed on the website are usually the cooling capacity of the unit at AHRI standard cooling conditions, not heating and not the cooling conditions you have in Seattle. You need to look at the performance data to learn that.

You don't need to make the minisplits any bigger than the load calculations require. The calculations already have some fluff built into them as a safety factor. Size them as close as you can. Also, there have been reports that multi-head minisplits can't take advantage of the modulating abilities of minisplits. My understanding is that the compressor steps up/down depending on which indoor units are running but can only go down as low as the minimum capacity of the outdoor unit, which is usually much higher than the minimum capacity of the indoor units. This lowers the efficiency of your units and can increase short cycling. Dedicated modulating compressors per head is better from an efficiency standpoint.

Thanks Martin, Yupster:

I've been trying to run down some additional data - the condenser model I'm basing this on is the 3MXS24LVJU. The attached I pulled from the engineering documentation. The indoor units are the CTXS07, FTXS09 and FTXS12. I couldn't find details on the ranges for the indoor units. The submittals included rated capacities but not min max levels. So if I'm reading the total capacity tables right for this combination, heating capacity at 23 degrees outside and 70 inside would be 27Kbtu/h correct? Enough to cover the 22.6 on the load calculations. The 24k btu/h is the first size that handles three heads.

I second going with 1:1 units. I'm planning a similar system in my 60 year bungalow.

You gain efficiency/performance (lower min modulation) and it seems like the cost isn't any higher. It might even be cheaper since you don't have to home run your line sets to a common outdoor unit, just to the closest exterior wall.

Without the full report it's a bit hard to tell, but there is one likely error showing up on the Manual-J summary:

Under "Construction Quality" the description is "semi-loose"...

...which defaults to much higher infiltration rate than most houses with blown insulation in the walls. When insulation is being blown into enclosed cavities the fiber follows any air flowing out of the cavity, clogging all of the exit paths, dramatically reducing air leakage in walls.

If the new windows are installed correctly they're not very leaky either. Competent attic insulation crews also air-seal all the plumbing & wiring penetrations etc. in the attic floor too. I don't recall all of the options in Wrightsoft (it looks like a Wrightsoft tool's output), but semi-tight is probably a more accurate description of your house.

They also used 70F for the indoor design temp, not a code-min 68F, and 25F for an outside design temp, which is lower than the 99% outside design temp for Seattle proper. If the real design temp at your exact location is 28F (Boeing Field's 99% temperature bin) and you're designing to 68F, the additional 4F difference in the calculation adds about 10% to the heat load number.

The BTU/hr per square foot of conditioned space is also suspiciously high, at 17BTU/hr per square foot. That would be more typical of a 2x4 framed house at 0F, not at the 99% outside design temps in Seattle/King County that run 25-28F. When temperature and air tightness factors are corrected I suspect the load would be on the order of 18,000 BTU/hr or a bit less, not the 22,630 BTU/hr number in the report.

Did the load calculation inputs include the R10 foundation insulation?

I don't believe the 3MXS24LVJU is a full-VRV system. While the compressor will step it's output up/down with different zones calling for refrigerant, the heads themselves won't modulate, even if those same heads modulate over a range when running on dedicated single zone compressors. That's why they don't give a range for the heads in a multi-split submittal and why it's usually / often more efficient (and more comfortable) to use separate modulating mini-splits rather than a 3-zone multi-split.

Both the FTXS09 & FTXS12 modulate down to 4400BTU/hr @ 47F when married to their respective RXS09 & RXS12 compressor units:

http://www.daikinac.com/content/assets/DOC/SubmittalDataSheets/072017/LV/FTXS09LVJU-RXS09LVJU-Submittal-Sheet.pdf

https://www.daikinac.com/content/assets/DOC/SubmittalDataSheets/Single-Split/FTXN12NMVJU-RXN12NMVJU%20Submittal%20Sheet.pdf

Daikin doesn't make a dedicated half-ton compressor for the CTXS07:

https://www.daikinac.com/content/assets/DOC/SubmittalDataSheets/Multi-Split/CTXS07LVJU%20Submittal%20Sheet.pdf

When looking at the capacity tables you should be looking for the capacity at an indoor temperature of 68F (which is code min in most locations), and the outdoor temperature nearest to (or slightly below) your 99% outside design temp. In your attachment they indicate a capacity at 23F outdoors, 68F indoors is 27,330 BTU/hr, which about 1.2x the calculated heat load, which wouldn't be terrible if the load numbers were real. But it's probably at least 1.5x the capacity of your real heat load.

Since you're in the middle of remodeling the basement you may be at the opportunity-moment for being able to install a modulating ducted mini-split. Fujitsu's -18RLFCD mini-ducted version delivers 21,600 @ +17F and more at higher temps. It would have sufficient capacity for the calculated whole house load at +25F. Daikin has a similar 1.5 ton ducted mini-split with similar AHRI capacity (2MXS18GVJU+ CDXS18LVJU) sold under their commercial systems, not their standard residential line up), but Fujitsu's unit has a wider modulation range and a beefier air handler, as well as a higher HSPF rating.

http://www.fujitsugeneral.com/us/resources/pdf/support/downloads/submittal-sheets/18RLFCD.pdf

http://www.daikinac.com/content/assets/DOC/2MXS18GVJU%20-%20MIXED%20-%20SDS.pdf

Thanks Dana -- the attached will give you a good Idea of where I stand remodel wise -- and yes I have plenty of opportunity to consider options. I appreciate the clarifications you brought to the report -- I'm sure they didn't consider the basement insulation as it's not installed among other factors.

I have looked at some ducted options because of the room breakdown - I've been a bit hesitant due in part to the issue of static and I've not gotten a sense from the HVAC folks who have visited that they have a good understanding. The Fujitsu was attractive in that it creates the potential for a vertical as well as horizontal configuration of the air handler. The likely location is next to a drain which means I could work with the gravity drain requirement if vertical.

If looking at the fugitsu, I presume it would be a matter of feeding ducts into each room. The attached picture is where the furnace distribution extended along the ceiling in the basement and fed the rooms and first floor previously.

I've got two questions - like I said, I've had 3 different firms come by, each with a focus on mini split and none have been able to give me much input regarding how to evaluate the static pressure requirements of duct work. I've attached the submittal for the inside unit that shows the performance curves. Are there applications to help with duct layout that I can ask the folks about?

Second -- one of the things that was a challenge for me with the furnace was the relative temperatures between floors -- the thermostat was located on the first floor and therefore the basement was generally colder in winter. Is heat consistency more a matter of sizing the ducts properly or are there other ways to control distribution with a single unit?

It's often difficult to operate a basement on the same zone as a first floor, since the heat loss characteristics of basements are different from first floors. Basements don't have as much above-grade wall as the other floors, and they don't have as much window, so don't vary without outdoor temperature as much.

If the basement was previously uninsulated concrete foundation wall the change in load with outdoor temperature could easily be MORE than the above grade floors. That will change once you have a continuous R10. The basement temperature overshoots/undershoots will be lower than when the basement was uninsulated. But if you have a modulating ducted mini-split those under/overshoots can be pretty much eliminated- it'll be running continuously most of the time during the heating rather than starting & stopping the way a gas furnace does. The temperatures can be roughly tweaked with a balancing vanes, and fine-tuned as-needed (and it will need some minor tweaking as the seasons change) using adjustable registers. If you "set and forget" the first floor's thermostat (and be sure to program it to use the remote's temperature sensor, thermostat style rather than sensing the return air temperature, which is the default), it's pretty much a matter of adjusting the flow.

Seattle doesn't have much of a cooling season, but I suspect most of the summer you'd want to close the basement registers way down, since ALL of the cooling load will be on the fully above-grade floor.

The heating load of an insulated basement is really quite small. If you opt to zone it separately, you may be able to control it with a duct zone valve on a Fujitsu 18RLFCD controlled a dumber type thermostat, but getting it right takes some design work.

The full load of the entire basement after the walls are insulated is probably less than 4000 BTU/hr maybe even less than 3000 BTU/hr. The Bedroom 3 & 4 loads of 3.3K & 3.7K in the Manual-J are almost certainly the "before insulation" loads. Going from uninsulated 2x4 walls inside the foundtion to R10 continuous insulation is going to cut the wall losses by about 60-70%, and if you're replaceing crummy single panes with code-min windows it'll cut the window losses by a similar amount.

Thanks so much for your time and insight Dana - I've done one more thing and then I'll stop pestering. I'd signed up for coolcalc and filled it out as best I could figure. The results seem more aligned with what you've been describing.

Looking at the LG - I'm hesitant to go with one head for the reasons you note. I'm back looking at two heads in different configurations.

Configuration one -- two separate units (condenser and handler)

Fugitsu 9RLS3Y - Wall unit 33 seer, 14.2 HSPF for the upstairs mounted as before

Fugitsu 9RLFCD -- Concealed duct 21.5 seer, 12.2 HSPF in basement with three runs (less than 10ft each - feeding rooms.

Configuration 2 zones

Fugitsu AOU18RLXFZ Compressor (22,000 heating capacity)

Fugitsu ASU12RLF1 Wall upstairs

Fugitsu ARU9RLF Ducted unit (9,000 - 10,000 BTU) Basement

The reason I include the separate compressor option is speculation about bridge seasons when basement is cold and may need a touch of heat where first floor is on the hot side and a little air is desired.

The AOU18RLXFZ will not modulate the heads, only steps the compressor up/down when the fixed-output heads are calling for heat. The minimum modulated output of the compressor is 6800 BTU/hr, which is well above (could be more than 2x) the actual DESIGN heat load of the basement, which could be a problem.

If you go that route, the ARU7RLF mini-duct cassette (nominally 8100 BTU/hr and still ridiculously oversized for the basement load) would be more appropriate than the ARU9RLF (nominally 10,200 BTU/hr, and ludicrously oversized for the likely basement load.)

If going with two compressors:

For the upstairs rooms a single wall unit won't necessarily provide enough heat for the bedrooms. The (likely inflated_ total load for the first floor in the calculations comes up a bit shy of 13,000 BTU/hr at a 50F delta-T. A 12RLFCD (delivers 16,000 BTU/hr @ +17F) mounted in the top or side of the closet between the bedrooms with the major duct pointed toward the living room, or in soffit built under ceiling level running over the bathroom door (in the hall) exiting at the cut-out for the kitchen, with very short but skinny runs would deliver better heat distribution. A 9RLFCD can probably handle the real load for the first, and may be more appropriate. There isn't a huge downside to going with the oversized 12RLFCD, since it modulates down to the same 3100 BTU/hr as the 9RLFCD, but it's physically a bit bigger, which may be important if the available installation area is tight.

If mounted vertically against the wall it takes up about 5-7 square feet of floor area, and the return could be one central grille in the hall space between the bedrooms. The attached shots are of the slightly larger 18RLFCD mounted vertically in a small house in CA. Note the very short plenum above the cassette with four ducts distributing the heat, one of which gets built into a soffit under the ceiling running down down the hall.

In the basement, the minimum modulation of the 9RLFCD is 3100 BTU/hr @ 47F, which may be more than your design load. It would cycle a lot more than the unit upstairs, but not NEARLY as much as it would if married to an 18RLXFZ compressor.

Thanks for the update and shots. I have a shallow linen closet in that first floor hall area between the two bedrooms that I considered for just such an option. my concern has been the access needed for maintenance etc. The picture you share appears to wall the unit in pretty tightly - what kind of access is needed to the line set or controller?

Removable panels or doors at the end where the lineset hooks up and access to the air conditioning condensate drain (which is guaranteed to develop a clog at some point) would be important. In the California installation you can see they left a big opening for a hatch/door over the return plenum grille for that access. It's a bit tight on the right side where the lines hook up- it probably would have made sense for them to also include a smaller panel/door on the right-most wall to be able to easily get a wrench on it. Ideally you would have sufficient access to be able to do a full replacement 0f the cassette without any demolition work if you had to, and positioned where it would be easy to swap filters, etc.

In your house it might be possible to install the unit for the upstairs in the garage or under the stairwell, with floor registers to the rooms above rather than wall registers. But maybe that's where the downstairs unit would go if going with a mini-ducted system.

Where are the existing gas furnace & water heater located?

Furnace was under stairs with soffit running along support beam- you can see the beam, path and a few remaining ducts in the picture from my 8:25 PM Post. I had considered that duct option -- that's where I get a little concerned about the static issue. The 9 and 12 K units look to have a fair amount lower cfm and I'd want to make the runs short. From under the stairs, the path to each vent location in upstairs rooms is about 10ft total but with 2 to 3 90 degree turns. You have any feedback on static issues? Runs to the basement rooms would be straight forward.

I'm going to look more closely at that closet -- the width is about 29 to inside of studs. If I pull that part of drywall that would extend to about 36. The dept of the closet is such that I could place a pretty good access door behind the door leading to the bedroom -- out of sight. I could run a soffit above the other bedroom door to get one vent to the main living room. I have to think about whether I could extend a small run over to the kitchen area.

Linwood Plenums in the UK make abs Plenums for fujitsu and others but I can't find anything in the US.

As an aside -- Fortunately I don't live in this mess right now -- I designed a back yard cottage just behind that I live in. Haven't done a blower test but the structure is tight -- 800 sq ft, zip system sheathing over stagger stud 8 in walls -- 3.5 in spray foam followed by batt. 6400 watt solar on roof facing south -- mitsubishi ceiling cartage. I messed that up a bit -- it's open ceiling to loft -- heat doesn't get to living room too well. The main house will be rented when complete.