Insulating subfloor in small studio (shed) with XPS

I’m finishing the inside of a small prefab shed to turn it into a little backyard studio/office (thanks covid) and I’m wondering about my options for insulating the floor. I plan to eventually do hardwood flooring inside.

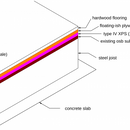

Currently the floor is 3/4″ OSB and there is no crawlspace – the joists (steel) are resting directly on a slab and there’s no access to the underside of the subfloor without ripping out the subfloor (which I’m not interested in doing).

I was considering using Dricore R+ panels – which seem to be basically 1/2″ 25psi (I guess, based on their rating of ~3k pounds/sq foot) XPS foam and 1/2″ OSB. The downside is R+ panels aren’t stocked anywhere locally.

It seems like it’d be easier/cheaper for me to just lay down regular type IV XPS (25psi) foam (lowes kingspan or foamular 250) and a layer of 3/4″ underlayment on that (either plywood or OSB) and screw that sandwich down onto the existing subfloor.

Any problems with that plan? Anything about this that’s going to turn out to be a real bad idea? I really don’t think the floor needs to be insulated (the shed is tiny and I could just put a rug down) but it’d be nicer if it were insulated somewhat.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

hospadr,

That's almost exactly how I insulated my own back yard shed. You will find that even with 25 psi foam the screws pull the edges of the plywood down a little bit causing some lippage between sheets, so you may need a second layer of 1/4" underlayment for some finished floors.

What's your timetable? Owens Corning is in the process of rolling out their new version of Fomular with ~10X reduction in climate impact. It is supposed to be available across the US starting Jan 1st.

Otherwise, you could order some "Type IX" EPS foam which has the same 25 PSI rating and even lower climate impact than the new Foamular.

There is simply NO point to using 25psi rated foam sandwiched between 3/4" subfloor. Even Type-I EPS or 1lbs density foil faced polyiso would be fine. There won't be enough flex in the subfloor/foam/subfloor sandwich to deform the foam, with the loads distributed by the upper subfloor, and the foam fully supported by the lower subfloor. Even the dynamic loads of a 250lb Czech doing the polka with a keg of beer on each shoulder wouldn't be enough to crush or dent the foam.

And of course using EPS or polyiso would be greener & cheaper than XPS. See:

https://materialspalette.org/wp-content/uploads/2018/08/CSMP-Insulation_090919-01.png

One lbs. density foil faced polyiso has about half the CO2e footprint of HFO-blown closed cell foam in that graphic (even lower than EPS), whereas 2lbs roofing polyiso is about the same as HFO blown closed cell foam.

Ooo well, I'm going to be doing the bulk of the finishing work over the next two weeks, but the flooring is probably the last thing I'll be doing so it's certainly possible that by the time I get around to the flooring I can just use that.

First, I'm guessing you're in a fairly mild climate otherwise you'd be a little more concerned about the total R value to keep the floor from being freezing cold.

Second, This assembly can add some height so have you figured out how to deal with the door and threshold? You don't want to have a 2"+ trip point every time you come in.