Insulated Mudsill – Expanded PVC, and Drying Potential

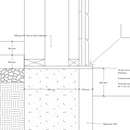

I am building a superinsulated house in northeastern Europe. Construction is something between a double-stud wall and Larsen truss wall. Interior wall being structural, 2×6 stud equivalent, exterior wall 2×3 stud equivalent. Walls will be insulated with dense pack cellulose.

One of my concerns is drying potential of the wall, especially near its interface with the concrete foundation.

Factors contributing to my concern:

– Insulated wall thickness of 400mm/16”

– Mild humid climate, average air temperature in warmest month is only +17.4C

– No basement

– Slabless floor is on 200mm/8” EPS foam, above level of concrete perimeter foundation

I would appreciate input on my idea of insulating the mudsill/sill plate from the concrete perimeter foundation using a 10 to 20mm(0.4-0.8”) layer of Expanded PVC product, Komatex specifically. Note, this is a fairly strong material, not to be confused with Expanded PVC trim.

Komatex specs:

Compressive strength >3 N/mm2 or >435 psi

Thermal conductivity 0.06-0.1 W/mK or R(US) 1.4 to 2.4 per inch

(R(US) 1.1 to 1.9 for 20mm/0.8” thickness)

Foundation is already poured at 400mm/16” width, perhaps a narrower kneewall with the outer stud/Larsen being cantilevered outboard would have been better in regards to drying potential.

Does such a small amount of an insulating layer under the mudsill actually contribute to drying potential(by minimizing wetting/condensing potential)?

Does such a use of Expanded PVC make any sense?

Thank you for all shared thoughts, sorry for the mix of mm/inches/U-values/R-values!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I doubt it would help much, if any, with moisture/drying, but it will help keep the interior warm enough to avoid condensation and mold.