Installing 15′ tall, triple mulled windows.

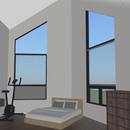

Here’s my problem… In our master bedroom we have a column of windows. The rough opening is 15′ tall and discussions with my engineer led me to the idea of removing cross members that previously divided the windows into thirds, so we could opt for just seeing the black window frames once they are all mulled together.

I went with Andersen 100’s, and the windows are here. The previous opening had the windows recessed a couple inches using a 2×4 buck. (which caused a million problems over time btw). The new plan is to use a 2×6 as a buck and place the window flange out flush with the osb sheathing.

Talking with the Andersen window rep, I had the thought that maybe this entire install should be non-standard.

Here is the plan I proposed to him and he thought was smart. Please let me know your thoughts.

1. Since we’re removing all the interior trim and the buck, there is really no reason the new 2×6 buck needs to be placed in the opening first.

2. Lay the windows flat, mull all 3 together.

3. Build up the new 2×6 buck and cover it with prosoco fast flash.

4. Fasten the window flange to the buck with the 1/4″ shims

5. Seal between the window and the buck while flat.

6. Seal the window flange to the buck.

Then once the window installer is here, simply place the buck/window unit into the rough, secure with a few screws, and then use expanding foam as the shim around the buck, and screw it off. Final step would be sealing up the outside with the fast flash.

The benefits I see here is that installing the entire window unit into the 2×6 buck while flat will protect the entire unit during installation and also let the sealing be perfect and easy .

Critique away 🙂

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Mike,

What does it weigh?

A couple of weeks ago I put in a 6 ft x 6 ft fixed window, and it took three of us to lift it into the RO.

Triple that. The plan is to use the glue lam timber above to mount an electric hoist, and to mount an angle iron down each 2x6 for rigidity during the lift and to provide a good mount point.

Mike,

I think it's a good plan from a few different perspectives. Your Anderson rep likes it. You can test fit the buck first, It let's you do a good job of the installation on the ground, and it removes the stress of trying to muscle it into the opening in parts or as a whole.

Awesome. Thanks. That's a great point about test fitting each buck...