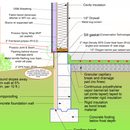

Input on Detail Where Wall Foam Meets Foundation Foam (Stucco Finish)

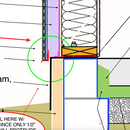

EDIT: I’ve attached a closeup since the image is kinda blurry.

Hello all, my question is explained on the attached detail, but in brief, I’m not sure why my stucco guy wants us to separate the foundation foam from the wall foam at the sill.

We’re building in Zone 4, Sedona, AZ. The house has stucco, over rainscreen, over 2″ foil-faced polyiso, over Prosoco spray wrap (plus miles of joint & seam and liquid flash), over OSB, over 2×6 framing, with 2×4 inset windows. The sill plate is sealed to a Conservation Technologies gasket below, which is over 5″x8″ painted L flashing installed on the top of the CMU stem wall, and out over the 2″ of EPS foam on the exterior of that same wall (see detail). The metal is because of the termites here.

I’d also love some input on how I’ve described the windows – installed to 2x4s inset into 2×6 wall openings & flashed to the OSB with liquid flash. Then foam is added over the fins – so the foam on top of the fins is flush with the wall foam – and flashed again with liquid flash to the exterior face of the foam.

We just passed our preliminary framing inspection and are starting the exterior foam install this week, monsoons depending.

Thanks!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I can't speak to whether it's necessary or not, but it looks like they are separated to provide a slope for water to drain out in case it gets into the wall foam. Could also be to allow for termite inspection, but that is usually below the metal termite flashing, not above it (from what I've seen in various diagrams).

Yeah, that's where I am too - just not sure what the purpose of that gap is is or whether it's needed, since it causes more problems than it solves. All seams in the foil-faced foam will be taped with Owens Corning seam seal and the OSB behind it is sealed with Prosoco spray wrap, joint & seam, etc. The stucco guys do beautiful work, but they aren't used to working over foundation foam or really anything other than crinkle wrap. I think they're trying to recreate what they usually do by terminating the assembly at an angle.

In your warm-ish climate, I'm not sure what the exterior foundation insulation buys you. Unless you need it for frost protection, I would skip it.

Bumping up the 2' wide strip of insulation around the outside perimeter of your sub slab insulation is a much better use of the extra rigid.

Skipping the foundation exterior rigid now simplifies your life the rest is standard details. It would also let you inset the wall so the exterior rigid if flush with the foundation plus the wall can now cover the slab edge insulation without having to do any tapering there (maybe even use a bit more slab edge insulation there as well).

Thanks, Akos (& Malcom).

I would definitely do things differently next time, but the slab is finished and the house is already framed. So unfortunately, it's now more complicated than it needs to be. Basically, I'm just not sure if we're OK sealing wall foam to foundation foam (with the thin termite flashing between).

We added exterior foam on the foundation to address the slab edge foam stopping below the top of the slab and to keep the insulation continuous from roof to foundation (the roof has 4" exterior polyiso continuous to walls). That angled edge detail is approved by the county so our engineer allowed it. I really doubt he would have let us offset the walls. We have 16 sets of PAB7 - 10 and SSTB16 - 28 bolts inside the CMU block foundation walls that mount to HDU8 - HD19 hold-downs. Yes, over 32 big holddowns. I can't see how we could have installed them if the walls weren't aligned. Also, the slab is polished, so if the edge foam was closer to the surface and not covered, it would show.

As this point, only the exterior wall foam and trim aren't installed yet - the walls are sheathed, the windows are in, and the Prosoco air/wrb is finished. The inspector signed off on covering the walls last week.

So... would you seal the wall foam to foundation foam below it (with no J/weep trim between the wall foam and OSB)? If yes, we'd then install the weep/kickout trim to the face of the wall foam and seal it with joint & seam so it acts as a secondary wrb. There would be no drainage behind the wall foam - between it and the OSB. Water that enters behind the stucco would drain through the rainscreen to the foil face of the foam, and down to the weep trim below. I'm just not sure why the additional trim protecting the bottom of the wall foam needs to be there.

I'm adding another detail from the same manufacturer, again showing the bottom of the rigid foam "protected" by metal trim. On mine, all except 1/2" of the foam is "protected" by the foundation flashing below it anyway.

This kind of stuff keeps me up nights and I really appreciate your input.

Kelly,

+1 on everything Akos said.