Mitigating Rodent and Moisture Issues at Rim Joist

We had a panel-built house constructed a few years ago*. It seemed like a great idea — affordable, high quality, rapid turnaround, etc. We love the house and are enjoying living in it, but the promise of “high quality” has been challenged by some details.

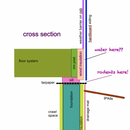

I’ve attached a picture I drew of a cross section at the top of the foundation. The hardiboard siding doesn’t go all the way to the grade — it doesn’t even go down to the top of the foundation, in some spots. I’ve also attached a picture from before the siding went on (showing the wall/rim setup), and a picture from after the siding went on (showing the gap).

Problem 1: There’s a gap at the foundation where rodents are enticed to dig into the wood-pulp insulation along the rim joist, and from there they find their way into the floor system.

Problem 2: That wood pulp insulation is not covered by a weather barrier; nor is the rim joist. If water gets behind the siding (does it? no idea), it presumably can trickle down to that wood pulp insulation, which probably acts like a sponge. Maybe that’s OK, we live in a super dry climate — big snows, very dry air.

I’m trying to mitigate problem 1, and would love to solve problem 2, or at least not make problem 2 more acute.

Does anyone have a great suggestion for mitigating?

* Conceptually, here’s how it works: A site builder gets the foundation poured, the panel builder stands the panels up on the foundation, the site builder finishes interior and puts on siding/roofing. All of that depends on extremely good collaboration at all the touch points — e.g., the sill. We didn’t get that collaboration. And many important things just fell in the gaps between those two teams, causing quality issues. Live and learn!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Solving Problem #1 should be relatively easy. I would use some hardware cloth in that "rodent gap". Wrap the hardware cloth around the insulation as best you can with the access you have, then push it into the gap by the sill taking care not to tear the tar paper. Seal the gap by the sill with some canned foam, being careful not to plug the drainage gap behind the siding. If you use heavier gauge hardware cloth, you could bend the hardware cloth to come out against the back side of the siding to keep rodents from going up into that drainage gap too.

If the hardware cloth will be entirely protected from the elements, you can use the usual galvanized steel stuff. If there is a chance of water or debris (soil, etc.) getting to the hardware cloth, then I'd go with stainless steel. TWP Inc has lots of mesh sizes and wire gauge options, and I've used them before. Heavier gauge is harder to work with, but also harder for rodents to push out of the way. Make sure to use welded mesh -- the woven mesh tends to unravel when you work with it in small spaces like this. You want at least 1/2" mesh for rodent protection, 1/4" is better (a little stronger, and NO chance of a rodent squeezing through).

Problem #2 is trickier. My first though is to use a fully adhered membrane here to extend the existing weather barrier over the wood insulation, but I'm concerned that might be a problem for drying. I'm not familiar with this type of insulation, but hopefully you'll get some reponses from others here who are.

Bill

The rim joists seems to be awfully close to the grade. Did you rake it back later in the construction process? Do you have gutters to minimize splashing back on to the structure?

> Did you rake it back later in the construction process? Do you have gutters to minimize splashing back on to the structure?

Some settling and some raking have pulled it down to more like 5-8" in most places. There are gutters. The photo I earlier attached is under a gable, so no gutters there. It has a good slope away from house.

Is what you refer to as "wood insulation" actually rockwool or mineral wool insulation?

If so, there is no issue with it getting wet.

The correct answer to the rodent problem is hardware cloth, as explained above. Based on the third photo, I'm betting the rodents are primarily getting in at the inside and outside corners. You can probably reach under there with your hand and feel the insulation. The correct answer is hardware cloth barriers customized to the conditions of each inside and outside corner.

My approach would probably be to fashion long strips of hardware cloth into a tear drop shape, and slide those in between the foundation and siding at locations at which the foundation is proud of the siding such as the right side of the third photo with the gloved hand.

Second, figure out a way to secure hardware cloth at locations where the siding is proud of the foundation to close the pathway to the mineral wool. This will be tricky - you might need to remove siding, which looks to be complicated. Another method at these locations could be to secure the vented portions of Hardi soffit if you can figure out how to secure them horizontally - maybe let the pieces rest on a ledge of the foundation secured with continuouse sealant, tilt it outward and secure to the backside of the Hardi siding with continuous sealant. Of course you could do similar attaching the backside of hardware cloth to a termination bar and securing the termination bar to the foundation. Securing is not quite the right term - it is using a sealant rodents wont' want to mess with to seal the gaps but still allowing the system to weep. This is the enticing area to the rodents - the will run along the ground and go right up into that mineral wool, through it and into the warm exterior spaces meant to act as a rainscreen. ug.

Third, fashion custom created hardware cloth barriers for all inside and outside corners. These can probably be secured with friction if you use heavy enough hardware cloth and big enough tabs you bend up into the gaps.

Good luck. I've done the above with a similar issue with vinyl siding and it solved the problem. Definitely use max 1/4" welded hardware cloth. They had 1/8" but it was 27 gauge. The 1/4" 23 gauge welded galvanized worked well.

Thanks for all replies.

I've had a couple contractors look at it, and neither suggested hardware cloth. Both suggested a Z-bar or some coil stock metal, shoved up into the gap where rodents are entering, and then buried below grade. I like the hardware cloth idea better because it preserves the drying/draining effect.

I definitely don't consider it case closed -- I'd love to hear other ideas! As always, I appreciate this community's thoughtful replies. Thanks.

It looks like you have a rainscreen gap, so solid flashing would be detrimental to drying there, that's why we all suggested hardware cloth :-) If you didn't have any ventilation gap behind the siding, then it wouldn't matter as much, but I still think hardware cloth is easier to work with. Hardware cloth can be bent in multiple dimensions, flashing really only wants to take linear bends and fights you like crazy if you try to do anything else.

Bill

Would you consider lowering the grade around the house about 6 to 12 inches?

Having that much “was wood” that close to grade seems like an innovation to rot, mold, insects and pests.

Walta

Jiggyj,

One of the essential features of a rain-screen wall assembly is a ventilation and drainage gap at the bottom of the wall. From your section and the photos it looks like your's lacks that, and it pretty important to remedy.

I hate to suggest this, because it is a lot of work, but if I was brought in as a contractor to correct things this is what I would do:

- Cut the siding flush with the subfloor.

- Install a pre-finished metal cap-flashing over the wood insulation leaving a gap between it and the bottom of the siding above for water to drain and air to move into the cavity. The spaces between the rain-screen battens need to be blocked with perforated flashing or strips of something like Cor-a-Vent.

- Extend the WRB down over the wood insulation

- Install a pre-finished metal cap-flashing over the exterior foam insulation and drainage matt below, which would extend up under the new strip of WRB - and would seal the gap you are worried about.

- Cover the wood insulation with a water-table made from something like Hardi-Trim. Keep an eye on the new water-table. With the grade that high it may need replacing frequently.

Here is a variant I did where the rain-screen gap extends down behind the water-table:

Malcom, that was very helpful. Thank you very much.