HVAC – How many pipes off the plenum?

I changed my furnace for 2 reasons 1. Previous unit was undersized and 2. The duct design was far from optimal.

I’ll state now that I’m just a regular home owner who’s bought a house with too many issues, the HVAC being recently discovered so I’m learning quickly, mainly with you help of you fine people and the Reddit community.

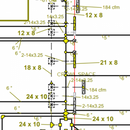

As my new Mitsubishi Zuba is being installed, I’m a little surprised to see the same amount of pipes (7. 4 off the top, 2 off the side and 1 off the back) coming off the plenum even though that the new plenum is much smaller than the old one since the Zuba is much taller. my design also called for mainly 6″ pipes instead of the previously used 5″. Again, the new plenum is much smaller. Side note – At the same time, I noticed that one of the pipes was spewing hot air since it wasn’t connected properly.

Does this match my duct design? Should I be concerned?

This is a $30k job so I was hoping for a drastic improvement.

My duct designer said that the plenum should be spec’d based on the requirements of the Zuba. The installers say that you can have pipes coming off the plenum if done correctly but this seems identical to before.

The way I understood it from what seemed to be a consensus from 3 quotes was that the plenum needs to build pressure and that’s not possible with too many pipes coming off it.

Thanks again!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Duct design is complicated. That said, generally the challenge in designing ductwork is keeping the pressure down to an acceptable level. The fan in the air handler needs to move enough air to move the amount of heat or cooling produced. The more resistance in the ductwork, the higher the pressure, the less air the fan moves.

Having many ducts coming off of the main branch is not by itself a problem. What can be a problem is if the ducts vary dramatically in their length, the rooms served by the longer ducts won't get as much air which may affect comfort.

If a duct system was designed properly it is straightforward to measure that it is working properly. The designer should have calculated a heating and cooling load for each room, and then calculated how much airflow each room needs to meet its heating and cooling needs. Then he adds up the airflow for all of the rooms and gets how much air the fan needs to provide. The documentation for the fan will tell him what the maximum resistance and pressure he can have and meet that air flow. He then selects duct sizes that put him under that resistance. Once the system is installed he measures the airflow and pressure in each duct to insure that it's working as designed. If necessary he adjusts the airflow with dampers and by adjusting the fan speed.

If the system is delivering the necessary air flow, it's working.

I totally get your points but the duct design calculated all of that, it seemed to be very detailed but I only included the screenshot of the layout.

I'm hoping for some insight based on that drawing, on how many much ducts come off the plenum because I only see possibly 2.

What I see is a main trunk that runs the length of the basement, starting off at 24x10, then drops to 21x8 and then 12x8. I count 16 ducts that branch off of it.

In this case, it seems so obvious that the vast majority of air will only makes it way it to 7 ducts directly above the air handler and there won't be much left to hit the rest of the line.

It's not obvious at all. That's why they're supposed to measure air flow and pressure after hooking it up.

I appreciate you taking the time to respond. I will ask them to do just that when they finish up. Thanks!