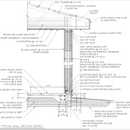

how would you erect this wall?

What would be the most efficient way to erect this double stud wall by myself, with only an occasional pair of extra hands? I was thinking I’d build the inner wall and attach it to the sill plate, raise it, then add the outer wall after.

A second question: The concrete person who installed the anchor bolts only left them 3″ proud, which isn’t enough to get through two plates. Can I just secure the bottom plate to the slab and then nail the wall onto it? Or should I cut all the bolts off and install wedge anchors? They also installed more than half of them more than 2.5″ from the slab edge, so those ones will be getting replaced no matter what.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I would install the wide sill plate to the 3" screws. On top of it build the outside wall first without the wide top plate.

I like to do all prep work while the walls are flat. This includes taping seams, install house wrap and rain screen strapping. You can overhang the sheathing 1.25" on the bottom which you can then nail to the sill plate after standing up the wall.

Simples to stand up a whole wall as one. This might need a couple of guys or wall jacks to do.

Once the outside wall is up, I would nail on the wide top plate and set your roof trusses.

When the place is dried in, you can then build the interior stud wall the same way. It helps to build the interior wall a bit shorter (say 3/4") so it is easy to tip up without hitting anything and install a 1x4 shim once the wall is up.

The interior wall is the structural wall.

build the whole assembly then use wall jacks. they are a cheap investment compared to the cost of materials which you can sell after you finish your build.

corners will be tricky to muscle in and make connections.

the completed wall assembly has a center of gravity past the face of slab so the anchor is doing a lot of work. [it doesn't look like vertical insulation at face of slab is taking any load from the wall above]. wedge anchors need enough edge distance so that they don't blow out the slab.

seems very likely that the eccentric loading will make the bottom plate compress the foam sill seall. you end up with a bottom plate that is pitched towards the outside. then all your walls studs will load on the inside toe where it meets the bottom plate.

you could counter-act this with structural clips bolted to face of slab -- there wouldn't be much energy penalty since they are inboard of the insulation. it's a costly retrofit. [look at something like wood blocking with simpson RCKW as a start point but it's a frankenstein solution] talk to your Engineer about remediation.

How committed are you to the bottom plate location? The simplest would be to nudge it inward enough so the anchors are in the insulation gap. This would also reduce the cantilever which would let you build the outside wall first followed by inside and then trusses. The extra exposed foam edge could be protected by a larger bend trim and some flashing.

If the bottom plate must stay, I would install some 6x6 or 8x8 wood corbels say 4'-8' OC lagged to the edge of the foundation. The 2x10 bottom plate can now bear on these for support. You can even make the corbels a bit wider than the foam and have them exposed, it would add a nice detail to the bottom of the walls. The bit of thermal bridging from the corbels is pretty much noise and not a big job to install.

Moving the plate inward that much would eat up about 80 square feet of floor space, interfere with service conduits and a drain that are adjacent to the wall, and screw up my garage door placement.

I might just use a 1 inch wider plate (rip 2x12 down to 10.25) and have the 2x4 sit 1 inch offset on it. That is if it's acceptable for the anchors to hold only the sill plate and not the 2x4 bottom plate. The drawing shows it going through both plates, but I don't know if that's just the default or structurally important. I've emailed the engineer, but historically his response time has been unpredictable and often long.

I'm having a hard time seeing the benefit of installing the outer wall first. Note that the air barrier and structural sheathing is on the inner wall, so there's not a lot to pre-install on that outer wall.

Deleted

Trevor,

Some unrelated comments on the section:

- You should show how the cellulose will be restrained at the eaves so it doesn't block the soffit venting. With no sheathing and raised heel trusses, I suspect your engineer, or the truss supplier will require structural blocking between the trusses over the exterior walls.

- You should also run the 1" deep baffles by your inspector, as the minimum ventilation gap depth in Canadian codes is typically 2.5".

- The section you posted cuts off the description of the strapping for the metal roofing, but the spacing looks wider than what most manufacturer's require.

- The slab edge insulation needs more protection against both mechanical damage and pests than parging to grade will provide.

The building department approved the plans, so I'm not too worried about running things by then that are already on the drawing.

The roofing attaches to purlins 24" oc. Is that not adequate? On a related note, I'm thinking of increasing the roof pitch from 3/12 to 4/12. I noticed the couple of roofing products I came across recommended 4/12 and up.

Trevor,

Lot's of things get missed on plan review that get called out during site inspections. It's worth clearing up things like the baffle depth with them prior to installation. Whatever you are using to retain the insulation probably needs to go on as you are standing the trusses, so again something to work out now, not later. The maximum spacing for strapping the 24 ga. snap-lock metal roofing manufacturers I use is 16". Again worth confirming prior to framing.

Build the inner wall first, attach it to the sill, and then do the outer wall—easier to manage solo. For the anchor bolts, securing the bottom plate to the slab and nailing the wall works fine. If you’re worried, wedge anchors are a solid option. Definitely replace the bolts too close to the edge.

Structurally I think you're in fine shape. I would use J-bolts, not Titen screws with that little concrete cover to the side, but I've used similar systems with 2x4 plates many times with no problems.

When I showed the attached detail to my structural engineer, he made me increase the mudsill to a 3x12 or 4x12, which I don't think was necessary with the interior wall being the structural layer and windows hanging off bucks attached to the inner wall, but it made him happy enough to stamp it. The snow load there is 50 psf.

As for standing the wall, it's far easier to have the outer wall as the structural layer, so you can stand that up first and stand the interior later. It's far easier to stand walls from the floor than from the ground. But that's not really possible with the inner wall being structural, so in your case I would frame both walls together and stand relatively short sections. And/or use wall jacks, which can literally be a life-saver.

At the top of the wall, do you have to have the trusses fully cantilever out? It looks to be a 2' overhang, which you can do with just the top chord of the truss, making it easier to contain the ceiling insulation and also eliminating the thermal bridge the bottom chord creates. Image attached, from the same project I mentioned above. (It shows the outer wall as the structural layer, as it's a 2-story house and I think it's easier to build with the outer wall being structural.)

The original drawing the engineer gave me had the bottom chord end right above the inner wall. I asked him to extend it to the outer wall to eliminate the thermal bridging, and that's what he supplied me. I know it's possible to do it the way your drawing shows, even with the inner wall being structural, because that's how the roof on my house is.

I've attached the first design for the shop. Do you think it would be reasonable to have them built like your drawing and then just add vertical members on-site that land on top of the inner wall? Or have them built like the attached drawing, and add blocking above the outer wall for insulation to go?

Yes I think either way would work for you, as long as you're not in a seismically active area or very high-wind area, in which case it could be complicated to get the necessary truss hold-downs installed.

With your design, I would extend the wall sheathing up to the underside of the trusses or notched around the top chords to make it easy to get insulation fully over the wall. Otherwise you have a significant thermal bridge at your top plate. Accuvent, the insulation baffle I recommend for dense-packed cellulose or wood fiber, has a baffle that can bend down to connect to the top place, eliminating the need for sheathing to extend upward.

There's no sheathing on the outside that I could extend, but I could add vertical OSB, shown in red. But if the accuvent will do the same, that would be easier.

They have a few options; this is the one I spec because the vent bays are 1 1/2" instead of the typical 1: https://accuvent.brentwoodindustries.com/products/accuvent-high-energy/. They have a few options for what they call starter strips, which will do what you highlight in red.

Trevor,

You will also need to add blocking between the truss cords to stop the cellulose bypassing the Accuvents.