How to seal bottom edge of rim joist?

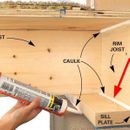

Marine Zone 4. I’m in process of sealing and insulating my rim joists. The process is straightforward but I cannot for the life of me seal the bottom edge of the rim joist. I just can’t get my caulk gun in there because the back end of it hits the ceiling (subfloor) and the tip doesn’t get to the bottom corner. I tried an extension tube but all that accomplished was making a big mess.

Should I just forget about it and rely on the rigid foam and canned foam combo for air sealing?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

User...031,

Where is your primary air-barrier? If it isn't connected to the rim-joist for it's integrity, I won't worry about it.

It's messy, but if the wood is reasonably clean (not covered with 110 years of grit dust, & mold) fiber reinforced duct mastic sticks to wood pretty well even over temperature & humidity cycling. The fiber-reinforced stuff can close gaps as big as 1/4" or more and remain flexible for life. Duct mastic can be applied with a small paintbrush, putty knife, trowel, your sister's toothbrush, just about anything works. Just be sure to lay it on at least 1/8" thick, or thicker if covering a bigger gap.

If the wood is a bit too grungy it can be vacuumed out and cleaned up first. In absolute worst cases it may need to be scrubbed with a stiff brush.

Dana, great idea. I can use a chip brush and a bucket of mastic I need to buy for my HVAC anyway. And the house just has 108 years of dirt and spiderwebs, so shouldn't require as much cleaning as a 110 year old house...

@Malcolm, the air barrier will be foil faced polyiso surrounded by a perimeter of canned spray foam.

If the subfloor is laid in a bed of adhesive, the only seam that may need caulking is the one between the rim joist and the sill-plate. The best time to do those is before the joists are installed, or less effectively, before laying the subfloor. That's also the easiest time to install foam between the joists, although it interrupts the framers, who can be understandably bad-tempered about waiting around.

That drawing appears to show a sill gasket under that sill plate. Caulking is less of an issue when a gasket is in place. I doubt very much you have any form of gasket in such an old house though!

How you seal this area depends on how things are built. In my house, I have open blocks on the top of the foundation wall, so there is a LOT of air leaking through. I’ve been putting HDPE sheet in as a capillary break, which also covers the tops of the blocks giving a flat surface to seal everything to. When I’m done, everything gets connected together in such a way that there are no air leaks.

I like Dana’s idea regarding using duct mastic. That’s a good product for bigger gaps than caulk can seal, and gaps that aren’t quite big enough for canned foam to properly fill. Remember that you can use fiberglass mesh tape like you use for drywall to help duct mastic to stay put while you’re applying it over larger gaps.

Bill