How to Insulate An Unvented Low Slope Roof Assembly?

We are trying to finalize our deck over conditioned space assembly (low-slope unvented roof) where we will have a continuous layer of exterior insulation but not sufficient space to achieve the requisite exterior insulation “ratio rules” to completely avoid the risk of condensation for Climate Zone 6.

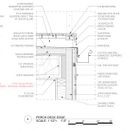

As shown in the enclosed drawing, our plan was to install tapered exterior insulation over our Advantech sheathing and install rockwool batts (r46) beneath the sheathing. We would apply a Zip protection board and EPDM over the exterior insulation. Because we’re using tapered insulation to achieve the desired pitch of the roof, a portion of the exterior insulation will only be 1 1/2″ thick (and up to 6 1/2″ thick). The exterior insulation on the low side of the roof will be far less than what is required to achieve the “ratio rules” for our climate (as noted in in this article – https://www.greenbuildingadvisor.com/article/installing-rigid-foam-above-roof-sheathing).

We have been considering the following options in order to modestly adapt our plans and yet lower the risk of condensation. What are your thoughts?

1) Install rigid above AND closed-cell foam beneath the sheathing? That prevents warm interior air from getting trapped next to the sheathing but would also mean that we have no way for the system to dry out if there is a leak since we have EPDM on top of the rigid foam.

2) Install rigid above AND rockwool batts beneath the sheathing, with a smart vapor retarder on the interior side of the batts to limit vapor drive but still permit the wall to dry out on the interior side. If we go with this approach, what installation details/considerations must we be mindful of to ensure we’re using the membrane effectively?

**Additional contextual info about the project:

– The project is located in Helena, Montana where there is a dry + cold climate (zone 6).

– We have 2×6 walls with Zip R (r9) and will fill cavities with rockwool batts.

– Other than our decks, we have unvented shed roofs made from SIPS panels (r49) pitched at 3:12.

– We are installing an HRV, humidifier + mini-split heat pumps for heating and cooling.

– We are halfway through our build so ideally want to avoid making dramatic changes to the design.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Aspen,

You posted your question twice. I just answered your question at the other location where you posted the question. Here is the link.

Aspen,

Most codes allow for reduced R value for compact roof assemblies especially ones with exterior insulation. In most case that between an R30 to R38 assembly.

In your case, I would bump up the exterior rigid slightly so the minimium is 2.5" (~R15) and 7.5" at the peak (R44) with about R29 in the middle.

Assuming R38 assembly, you can now install R23 batts bellow. The batts need to be pushed up against the roof deck and held in place either by stapling the facers to the side of the joists or with insulation wires. This won't meet condensation control at the edges but will be more than enough for condensation control elsewhere which allow for a bit of extra buffering capacity. With a well sealed air tight ceiling bellow, I would not worry about it.

This avoids SPF completely.

P.S. You can also look at sloping the I-joists instead of tapered insulation. Means a bit of extra framing on the bottom to get a flat ceiling but you can now simply use 4" flat insulation on the top for the whole roof. Even better, have them hang the ceiling on shimmed resilient channel or hat channel on resilient clips and you get a much quieter room bellow.