How to determine CFM of supply air room-by-room

I’m trying to get up to speed on air distribution systems. I’ve (somewhat hastily) read Allision’s great series on duct design*, but it doesn’t appear to mention how we determine how many CFM a given room needs for cooling/heating (though he does explain how to size the ducts for a given CFM).

On the one hand, it sounds like we use Manual J to size the equipment, and then there are rules of thumb for how many CFM per 10k or 12k BTH/h we need (system wide). So it should follow that we need to do a room by room heat loss/gain calc (manual J) and use those BTU/h numbers to determine needed CFM per each room or zone that a supply is serving.

But when I google this question, the toe-deep results appear to be that CFM per room numbers are determined by the type of the room (e.g. bedroom vs living room) and how many air changes per hour it should undergo based on some rule of thumb (so room volume and type of room). Presumably this is simply an air quality metric? Am I just getting results based on ventilation and not at all on cooling/heating? Its remarkable how many of the results are so extremally vague and convoluted.

So suffice to say I’m pretty confused. How do we determine how many CFM a given room needs?

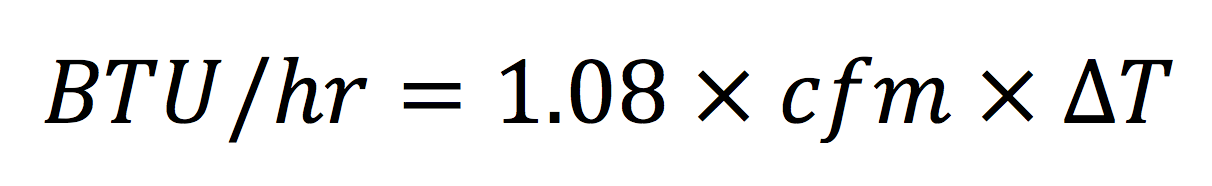

Bonus question is: how to we know which CFM per ton number to actually use? The rules of thumb for cooling has been stated as 400cfm per ton, and for heating I have seen large ranges. What data are we using to actually KNOW the correct CFM per ton for a given system? It seems that what it should depend on is the delta T, given that in the equation

It is really the only variable when BTU/h is given and solving for cfm. So is the CFM per ton number we use dependent on the expected (or maximum?) delta T of the system in question? If so, what data would that be gleaned from (i.e. is it a line item on the submittal)?

*https://www.energyvanguard.com/blog/duct-design-5-sizing-ducts

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You want to size it for heating and cooling loads. The air quality concerns have to do with ventilation air, which is usually done separately in the rooms where that's a concern, typically bathrooms and kitchens.

If you want to do it properly, you have to figure out what the CFM per BTU is for your system -- what the equipment you've selected is actually going to be delivering. And you have to figure out both winter and summer. Since heating loads and cooling loads aren't symmetrical, you're going to have to size for the greater. In the other season you'll have to use dampers, or if you have a zoned system the zoning should take care of it.

There is a recursive element to it, because duct design affects CFM.

Thanks.

Isn't the duct design really the 'knob that we can turn' in order to reach the desired CFM for a given room? (assuming we've chosen an AHU with a given spec?) In other words, we match duct design to the blower characteristics to achieve the desired CFM?

In which case, I assume we would design the ducts to accommodate the highest CFM we might need, i.e. design temp load btu/h requirements?

I guess this question is less about duct design though and more about how to determine desired CFM; I'm wondering how we know the supply air temp, which I assume we need in order to calculate the delta T in order to calculate the CFM for a given btu/h load.

Manual J calculation is the first of 4 calculations for a proper install.

J, S, T and D

You may find this link interesting.

https://mrcool.com/blog/understanding-calculations-for-manual-j-s-t-and-d/

Walta

Thanks. Do one of these protocols actually specify how to calculate the CFM needed per room? The quick read doesn't seem to indicate which one calculates needed CFM. Though I understand that the manual J (if done room by room) would give us the btu/h design load which we need to calculate CFM. It appears we also need to know the delta T, which implies we need to know supply temps...

The way I understand it they are building blocks.

You start with the manual J estimate to establish the load then manual S to select the equipment. Manual T uses data from J to select registers and flow requirements for a room. Only then do you have the data to run the manual D to size the ducts required to deliver the correct flow to each register.

Walta

These video from Corbett Lunsford's Home Performance Youtube channel might help.

How many CFM's Does My Home Need?

https://www.youtube.com/watch?v=CuLBSFHd18c

Individual room zonal pressure testing.

https://www.youtube.com/watch?v=orp-sXTjTPw

that first video is actually a prime example of the confusion I am discussing here. He talks above air changes per hour (or air cleanings) of a room based on size, using a simple divide by 60 rule. But he's discussing this in the context of an AC air handler. So where's the discussion on heating/cooling load there? Is that video strictly about ventilation and he's just assuming we understand the heating/cooling load might dictate a *different* CFM number than the ventilation rule? When people discuss CFM per ton, it's really in reference to the heating/cooling load, not to air quality ventilation...right?

So the needed CFM per room (and subsequently the duct size) is determined by heating cooling loads for that room... right? Perhaps during the Manual T process as Walta suggests.

Or does this ventilation rule of thumb end up trumping the CFM dictated by the heating/cooling load. Do they play together or are they in different sand boxes?

I can't make sense of all the assumptions being made when people talk/write about this subject.

He does get into the CFM needed per the load calc in the second video at around the 5:20 mark and it makes sense.