How does HyperHeat work? re: comparing heat pumps

I recently looked up some numbers in response to another Q&A thread on heat pumps (here: https://www.greenbuildingadvisor.com/question/new-heat-pumps-malfunction-or-unrealistic-expectations) and was struck by the data from the Mitsubishi HyperHeat units compared to conventional heat pumps.

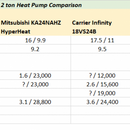

I pulled the data below off submittal data but not sure how to read it. Seems to me that the carrier two ton units match or outperform the Mitsubishi on SEER and HSPF however the actual BTU performance looks pretty bad. For example the 18 SEER Carrier drops 50% of it’s heating output from 47 to 5 degrees F. How is it possible for a 13 HSPF unit to underperform a 9 HSPF unit by so much?

I realize “2 ton” is a nominal size so these could be apples to oranges comparisons. The Mitsu could simply be a bigger unit marketed as 2 ton.

What exactly is the Hyperheat doing to make those abundant, low-temp BTUs possible and why doesn’t Carrier pick up on that? And how come Carrier’s low performance merits such high HSPF ratings?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

The special sauce used in cold climate heat pumps is called "enhanced vapor injection" (EVI), which is a little hard to explain without a diagram. The diagram here is pretty good:

https://www.arcticheatpumps.com/evi-dc-inverter-for-heat-pumps.html

The key components are a special three-port compressor and a refrigerant heat exchanger. The compressor has with two input ports, the regular low pressure one and and a medium pressure one. The medium pressure input to the compressor comes from refrigerant vaporized in the heat exchanger. One way to look at it is that it provides the high temperature lift capability of a two-state system without needing two compressors.

Lots of people are using it now, including, I believe, Carrier in their "greenspeed" systems.

Deleted

Good info on EVI, here's a couple of pressure-enthalpy diagrams, which shows the injection of gas during compression. The curve is saturated liquid and saturated vapor, you can see where it intersects at about the injection takeoff. The combined diagrams includes labels (source for combined https://docs.lib.purdue.edu/cgi/viewcontent.cgi?article=3423&context=icec).

Overall: "additional high condensing temperature capability at low evaporating temperatures due to the cooling effect of the vapour injection".

From Emerson:

As shown in Figure 1, the liquid out of the condenser is separated into two parts. A smaller part of the liquid, i, is expanded through an additional expansion valve, and then directed (or flows) into a counter-flow plate heat exchanger, HX. The main part of the liquid out of the condenser, m, is then cooled down through the economizer while evaporating and superheating the injection mass flow. This additional plate heat exchanger, more generally called economizer, acts therefore as a subcooler for the main mass flow m and as an evaporator for the injection mass flow. Superheated vapour is then injected into the intermediate vapour injection port in the scroll compressor.

The additional subcooling increases the evaporator capacity by reducing the temperature of the liquid from TLI to TLO, thus reducing its enthalpy. The additional condenser mass flow, i, increases the heating capacity by the same amount. Efficiency with vapour injection scroll compressor cycle is higher than that of a conventional single-stage scroll delivering the same capacity because the added capacity is achieved with proportionally less power. The injection mass flow created in the subcooling process is compressed only from the higher inter-stage pressure rather than from the lower suction pressure.

The operating envelope is also larger with vapour-injection, thanks to the cooling effect it provides. The envelope extends where compressor without injection is limited by the compressor high discharge gas temperature, ie, at higher pressure ratio zone. The cooling effect of the compression process is achieved by the addition of superheated vapour to the compression process at the intermediate pressure and at temperature TVO, controlled by the injection expansion valve. Superheated vapour is injected into the scroll set at the intermediate point of the compression process, via two symmetrically positioned ports as shown on the left hand side in Figure 2. The size and position of these ports have been optimized to ensure maximum COP and capacity benefit at typical operating conditions. The superheated vapour enters the compressor via an additional inlet connection on the compressor shell and flows to the injection ports of the fixed scroll via a tube . . . .

https://climate.emerson.com/documents/enhanced-vapour-injection-for-zh-copeland-scroll-compressors-technical-information-en-gb-4215484.pdf

Thanks--that combined diagram is really helpful/

Agreed ;-)

Charlie.

How would you go about confirming is the Carrier Greenspeed model has EVI? I tried to look it up but the closest I got was that it has a two stage scroll compressor.

Any other brands that come to mind? I require a 5 ton heat pump.

Many thanks

This document appears to state that some 5 ton Carrier has an injection system. See slide 34: https://cematraining.com/wp-content/uploads/2021/01/2021-Next-Generation-5-stage-Variable-Speed-Deck-1.pdf

Next Generation Infinity with Greenspeed®Intelligence and Evolution™Extreme & 5-Stage System’s

In the 5-ton only

•Increases capacity

•Part of the vapor-injection circuit

•Injects sub-cooled liquid from the condenser into the heat exchanger

•Injects into the mid-port of the compressor.

•Sub-cooled liquid then leaves the other side of the heat exchanger further sub-cooled before exiting to the evaporator

HSPF is pretty much useless, as it can't know what the building's heat loss and design temp is. It doesn't account for lost capacity, so if the heat pump covers 100% of heating load it works somewhat okay, but once you get into resistance back up, it's not worth anything. I'm not entirely sure, but I don't think it handles modulation either. So just a trash metric for modulating heat pumps, especially those with high performance at low ambient temperatures. There seems to be a tradeoff between performance at higher temps and performance at lower temps (you can see this within a manufacturer's product line).

SEER is cooling related and has no connection to HSPF.

Gotcha, what about COP? The Carrier values seem much higher as well, e.g. 3.6 and 4.7 at 47 degrees vs 3.1

Is the Hyperheat technically using more energy to produce those BTUs at low temps via injection?

You can use COP, but it's pretty involved and you need access to the whole range of outputs and inputs, which Carrier and Mitsubishi do provide, but not everyone does. You can't just use the COP ratings from the submittal sheet, because that's at an output that won't match up with the heat loss, unless you're extremely lucky. The concept is: determining heat loss at different outdoor temps, finding the COP that corresponds to that output (COP significantly varies across outputs for the same outdoor temperature ie. Mitusbishi's 24k Hyper Heat lists COPs of 2.43-5.09 for Max-Min output at 47), then looking at historical data to find out how much of the year is spent at that temperature to get a weighted COP.

I expect the Greenspeed is more efficient for most applications, but in climates with substantial cold temps, the Greenspeed COPs miss a lot less because they exclude the low efficiency backup heat. Likewise, the rated COPs for 47 aren't helpful unless 47 is near the design temp, since both rated COPs are at ~24,000 btus/h. Most houses considering these heat pumps would have heat losses of about 24k at design temps well below 47, so would have heat losses about 8k at 47 if the design temp was around 10.

Edited to add Labeled Diagram (noting it's idealized)

In a simplistic way, if you can cool the fluid, you get a bigger Delta T, which means you should be able to transfer more heat energy from ambient (outdoor conditions) to the fluid (for heating your home). The key is to not "waste" the extracted heat energy in the cooling process.

Note how the heat exchanger (economizer) provides two functions: "The main part of the liquid out of the condenser, m, is then (1) cooled down through the economizer while (2) evaporating and superheating the injection mass flow". The heat extracted goes into the injection mass flow, which is then injected into the compressor (little to minimal waste); noting that "The injection mass flow created in the subcooling process is compressed only from the higher inter-stage pressure rather than from the lower suction pressure."

I'd say that the additional components don't introduce a whole lot of losses (e.g., economizer, etc.), perhaps some drag as pushing fluid through a heat exchanger has some associated pressure drop.

I like to think of the way HyperHeat units work is that they are running some of the refrigerant thru the compressor twice. So they end up with a higher pressure and temperature gas at the output.

Walta

The current AHRI ratings are only testintg heat pumps at 17 and 47 degrees. So the HSPF numbers are based off the units output at those 2 temperatures. The manufacturers give the colder outputs at 5 degrees but the AHRI is not testing the unit at 5. So a manufacturer only needs to focus on good efficiency at those 2 test points only.

The Carrier simply performed better at 17 and 47 than the Mitsubishi did in the AHRI testing. It would seem Mitsubishi's better cold output makes the unit not as efficient at 17 and 47. I do remember reading that non cold climate units will often perform much better in milder weather than hyper heat units.

If you are looking for a hyper heat Carrier heat pump look at their mini split line up. Here is the tech manual for their hyper heat lineup up to 3 tons which is compatible with a number of their standard fan coils or furnaces.

https://www.shareddocs.com/hvac/docs/1009/Public/0C/38MAR-08PD.pdf