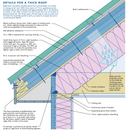

Detailing Airtight Overhang Using Exterior Foam Insulation

Climate zone 4.

I had downloaded the attached cross section from GBA somewhere. But as I finally get to the point of my design where I’m interested in the specifics of the roof overhang, I’ve got questions…

I’m expecting 3 layers of 1.5″ foam (not sure which yet, though I’d like to just use some type of Rockwool product for the added noise benefits) insulation on the roof deck.

But it looks to me like the attached screenshot would make every single rafter a significant thermal bridge, as it pokes out from under the home’s cozy blanket.

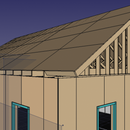

I had planned on… somehow… extending the eaves out and down, as well as extending the gable ends, for a 1’10” overhang all around. Attached is a sheathed before-insulation view of my plan so far.

What’s the good way to achieve the overhangs typical of traditional construction while still getting close to the monopoly-house air sealing and insulation benefits?

Edit: The roof is a truss roof, except for the gable ends.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Tyler,

This involves out-of-sequence additional framing, but photo 3 here shows one way to achieve truly airtight overhangs:

https://www.buildingscience.com/documents/insights/bsi-081-zeroing-in

I recall Matt Risinger had a YouTube video building similar 'outlooker' framing. This has been value-engineered out of projects I've worked on in favor of a ccspf seal around the truss tails from rigid insulation to the underside of roof sheathing. Likely not as good, but decent results on initial blower door test.

Found the video:

https://youtu.be/yTbMVdmnNlw

> This has been value-engineered out of projects I've worked on in favor of a ccspf seal around the truss tails from rigid insulation to the underside of roof sheathing.

Can you elaborate on this, or provide a drawing? I think you're saying to spray foam around the eaves where the truss tails stick out, so that they're encased in foam. Would this provide no where for drying to occur, or is that not a concern for some reason?

Thanks Tyler and Jason - this is exactly what I'm looking to do as well. This is great; keep us posted on your progress Tyler!

Chris S: I post my progress periodically on the Freecad forum as well as on my Diaspora - you can follow me at [email protected].

This was being discussed the other day here: https://www.greenbuildingadvisor.com/question/wall-furring-strip-termination-at-roof-with-roof-exterior-rigid-insulation

Zdesign has a good picture of making attached overhangs using tension members ABOVE the insulation and the beam/compression members are all attached (meaning exterior to the wall plane).

A boxed overhang will be easier to make strong in this scenario given the strength of a triangle--if done right.

Mineral wool might make this sort of detail tougher given it's higher compressibility.

Another good discussion here that focused on the rake overhang: https://www.greenbuildingadvisor.com/question/how-to-attach-roof-rake-and-ladder-over-thick-exterior-insulation

Jason: Wow, so that Risinger vid looks like the best way to go from a performance perspective. Thanks! Probably too involved for me at present. Can you elaborate on your CCSPF solution?

Tyler K: I think what is being described in your post #4 is what I had in mind. Box cornice constructed of 2x4's on the flat from the roof in tension, and then a return back to the wall beneath in compression?

It sounds like no one is really enamored with the cross section I posted due to that damn rafter sticking out.

I'll follow up with what I _think_ is a good option here, stay tuned.

Edit: OH RIGHT! Here's the video I originally saw on this. https://www.youtube.com/watch?v=4OrpDp5_3Rk

But it's not really clear to me how, in this design, the 2x4's from the roof are structurally connected to the "ladder style blocking" from the wall. I can't imagine the fascia does much...

I didn't "trim" any of these yet, and the wall foam insulation isn't there yet since I'm just experimenting with how it fits together... man I don't think the corner of the overhang is gonna fly with the inspector. That's a lot of cantilevers...

I'd also seen a version of that pro-trade craft video, but the one I saw showed even less detail. ha.

I think they are just using the fascia for the structure. The principle seems sound... you just need to make sure it's beefy enough a connection (use a sub-fascia if concerned?). An alternative could be offsetting the ladder blocking and screwing through the ladder blocking into the edge of the 2x strapping.

On your rake, I think part of why it looks weak is because the fascia is missing—something that would help tie it all together and strengthen the cantilever. For some reason I wanted to move your fly rafter up to where it's covering the edge of the foam, putting it in line to join directly with the fascia, but that may just be my eye was longing for a connection at that point.

If you did move the fly upwards, the 2x4 on the flat above it could be screwed to the fly creating a sort of L beam, though I'm not sure it's needed.

The key to that detail seems to be supporting the fly. It looks like your doing that from below your foam layer. I think some choose to do that from above the foam. Either works, but the way you have it now seems to slightly complicate the air-sealing, depending on your strategy. Doing it from above might look something like what Zdesign has in the photo I linked.