Help Understanding My Minisplit System

Recently I had a Mitz multi installed (MXZ4C36NAHZ-U1 with three indoor heads – MSZFH09NA, SEZ-KD15NA4R1-TH, MLZ-KP18NA) and I have been trying to figure out a few things with it, largely around its modulations or lack of. I have been using an IotaWatt to monitor its activity.

The first challenge I had was being about 8-9C above desired set points upstairs (SEZ and MLZ units) but the basement unit (MSZ) was right on. The SEZ unit has the M1K1, the MLZ and MSZ units have remotes (I wanted m1k1 for MLZ but apparently not compatible?). I had a fear of not having wall mount units from some of the readings on this site so I started to suspect the ceiling unit was not reading the room correctly (maybe influenced by nearby windows or attic?) and that was throwing off the entire main floor. Turns out, it was all the fault of the downstairs unit cycling on and off a lot. It is mounted on an outside wall and the hole through the wall was not reinsulated after being cut for refringent lines which was causing very cold drafts on the unit. This caused it to panic and throw a bunch of heat out. It would turn on and off 9 or 10 times an hour. Given it is smaller unit, I think this meant the upstairs units were continuously bleeding out the excess heat keeping it too warm (consistently 25C even if set point was 16C). As soon as I shut off the downstairs unit, upstairs set points became accurate within 2C, which is close enough for me (The M1K1 was right on). This was a good reminder for me to go around and check out how well the installation was completed. I insulated that area properly and now it runs much better.

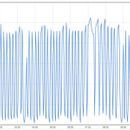

The upstairs units set points don’t appear to be a problem anymore, but I found that both units appear to be short cycling to maintain this (see example photo). I am calling it short cycling because it seems to go from near 0 to 1500 or 2500W several times an hour but I really don’t know if that is accurate or if this is actually running as it should. It appears to me that it doesn’t seem to be taking advantage of the modulation abilities, at least from a home owners perspective. I am still tempted to get an external temperature sensor (Mitsubishi M21-EAA-307 M-Series Remote Temperature Sensor) because it makes more sense to me but I suspect it will continue to do this as the ducted unit with m1k1 still seems to be behaving the same way. Any thoughts on this would be appreciated! Is this normal behavior or is there room for improvement and do you think external temperature sensors may help? It seems very intent on keeping the temperature very stable, which is nice, but I would almost prefer it to run a bit longer and turn off longer rather than all of the on/offs it currently is doing.

A bit more background about the system. It is near Peterborough, ON and the temperature has been around 2C/36F for most of the day that picture of the electrical monitoring was taken. I am fairly certain my system is probably a bit oversized so given it isn’t too cold in combination with the sizing maybe this is causing the ups and downs in use and it is more of a seasonal or sizing result? I had three heat loss calculations completed (26000, 34000, and 55000) as well as Akos helped me out on a previous post and estimated low to mid 20k’s. The contractors I was dealing with laughed when I said that number (I still think it is likely correct but they were not open to it!) and the smallest I could convince them to go was the MXZ4C36NAHZ-U1 (and this was with the best contractor I could find, the others just stopped dealing with me). As a homeowner, this was a frustrating process given how important heat loss calculations are for sizing heat pumps. To have so much variation and error potentially around these values plus contractors that would much rather err well on the high side. I don’t know what the solution to this is, but it seems like a problem, especially for heat pumps, to get correct sizing going forward. I don’t know how many times I have seen post on this site attempt to correct crazy heat loss calculations others have completed, but it seems like a lot and many people likely don’t catch it if they don’t use a resource like this. Another short aside for others in this position, really push for 1:1 units. I know that has been said many times on this forum but it seems even more obvious to me now. I tried to get a mini ducted 1:1 and 1:1 ceiling cassette and couldn’t find anyone that wanted to/thought it was a good idea. Most contractors would have installed four or five heads of one multi if I hadn’t pushed the matter. I think my system is going to work well, much better than electric resistance I had, but I still am kicking myself I couldn’t find something to do two 1:1s. I have a 1:1 in an out building and it seems to run much more smoothly.

Thanks in advance, this community has been very helpful!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Your unit is running properly. Unfortunately, it is oversized.

Generally the way these run is each indoor unit runs at its rated output or off (ie a 9k wall mount runs at either 0BTU or 9000BTU). The outdoor unit modulates to meet the demand from each indoor head calling for heat. So in this case, the outdoor unit will run at 9k,18k,15k or any combination of these.

Most units run around a COP of 3, so you would be seeing 800W,1400W or 1600W on the outdoor unit. This seems to match the graph you attached.

If you want to reduce cycling, try setting the indoor unit in the living space to a setpoint above your the other heads. This will get you longer runtime and less cycling.

It is unfortunate that HVAC techs push oversized units onto costumers. Since nobody, except an energy nerd, will complain about these issues or notice the higher power bill, they can get away with it. The best way I have found around this is to always ask for price on installing a specific piece of equipment instead of letting the tech decide what is "best for you".

Thanks Akos. I was afraid of that. Tough lesson to learn but I guess I will be better prepared the next time I take on one of these projects. Hopefully that isn't for a while though.

Is there any sense what the energy penalties are with an oversized unit or is it too variable? I am averaging 886W usage so far today, which is much better than what it would have been with resistance heating, but I would be interested to know what correctly size unit would be using.

I have the MXZ-3C30NAHZ2 with SEZ ducted 9, 12 and 15, for a heat load of 27kBTU/h (Western Montana). It's rated at 27.6 kBTU/h ducted (yours "36" seems to be 45 kBTU/h). The contractor suggested separate heat pumps, one down and one up, but I said we could manage the transition periods OK, which we've been able to do. The HERS rater was really close on heat load and everyone said "undersize". Two control units are wall mounted and one is not, usually leave it on the kitchen counter so it's easy to grab and adjust. Also tried a few different locations. I tweaked filters and insulated (blanketed) each SEZ in R8 or R13. Things seem to operate OK. I posted month-by-month kWh in another post, max around 1300 kWh (coldest months) with set at 70 F, min is around 100 kWh in Sept. Don't hesitate to ask any questions.

Thanks PBP1. That is interesting and good to know. Do you remember what that post is called? I wouldn't mind reading it. It will be interesting to compare numbers when I have more time monitoring my system. Assuming the lower estimates I have for heat loss are correct, we likely are fairly similar in BTU requirements except I have an oversized system. If I am anywhere near your numbers, I would be pretty happy.

It was a bit unfortunate for the multis there isn't anything between the 30NA (~28kBTU/h) and the 36(~45kBTU/h). That was quite a difference and my contractor just didn't think going that low (even if 25-30k for heat loss was correct) was a good idea. I get where he is coming from to some degree, he really didn't want us being cold in the winter and still thinks our current system might not be enough. Do you have to use auxiliary heat during the cold months or does it do everything? Does your 30NA short cycle much during the shoulder seasons or does it even out more? Thanks again for the information and the help!

Here's the post, see his numbers and mine. https://www.greenbuildingadvisor.com/article/urban-rustic-a-passive-house-energy-scorecard

With 20 mph winds and ave daily temp of 1.5 F (low around -10 F), the heat pump can keep the great room (23x30, shed roof 9' to 13.5' with 5 sliders and three large clerestory windows) at 68 F (morning temp) and rest of house is at 68 F to 70 F (2,100 sq ft total, 700 up and 1400 down). We do have a direct vent gas fireplace (Napoleon vector 38), which we never run overnight (it does have room temp on/off control) and only sometimes for a few hours in the evening and almost always on low (12kBTU). It's not really set up for heating but it will add some heat. Same with the oven (36" Miele convection, which actually has a blower that circulates air around the outside of the cavity and into the room). As to power usage, I have an efergy True Power Monitor on everything but the heat pump so I subtract that from the total, unfortunately I don't get second by second heat pump data.

Three indoor air handlers:

SEZ 15K for first level great room 690 sq ft (shed 9ft to 13.5 ft)

SEZ 12K for upstairs single room + bath 700 sq ft (shed 7.5ft to 11.5 ft)

SEZ 9K for first level bedroom, two baths and utility/pantry room ~700 sq ft

> energy penalties are with an oversized unit

Or perhaps the energy benefit:

https://www.aceee.org/files/proceedings/2014/data/papers/1-371.pdf

Very interesting, that is a different take than I have seen before. Thanks for sharing

Generally the problem is with oversized multi splits connected to a bunch of very small heads. In those setups, you end up with a lot of refrigerant bypass around the heads not calling for heat and terrible efficiency.

Provided this is not happening, cycling won't effect your heating performance but will be pretty bad for humidity removal. You might need to configure your units to turn the fan off in cooling to avoid re-evaporating condensate from the coil between cycles.

Jon's link is for oversizing on one to one units. Those are lot more forgiving and tend to have much better modulation range. For those, in most cases a bit of oversizing does increase the efficiency.

Multi splits operate differently, in some ways they are closer to a fixed speed unit than a variable speed. Exact effects is still unknown. I can tell you from personal experience on my oversized multi split that I use for cooling only, cooling efficiency is pretty low.

Good points. That is why I was originally thinking my multi wasn't performing right, it essentially looked like it was running as a fixed speed unit. It seems like these multis are pretty popular and the Mitz rep my contractor was working with pushed them pretty hard and even stated they modulate almost as well as the 1:1. Hopefully they can improve on this feature or at least make it more clear where they are best suited.

That is a good idea about the fan off, I'll look into that.

I think the 9K in the basement is my weakest link based on how small it is relative to the outdoor unit. The little bit of experimenting I have done I expect I will have it off most of the year except the coldest days. The basement is insulated quite well, we like to keep it cool, and the ducted unit does have one output in the basement so it gets some heat off that. I don't think it will need much and I don't want it causing unnecessary heat upstairs. Is it a problem leaving them off the most of the year? During the day, I think I will leave the ceiling unit a degree warmer than the bedroom ducted so it does the work. With doors open, unless really cold or hot, I think the one unit can do the majority of the upstairs heating.

Residential air-air heat pumps have a lot of room for improvement. Full modeling software so you can predict in-use performance, multi-head variable refrigerant flow, heads for very low loads, affordable "to water" indoor units, coordinated multi-room thermostats (with adjustable dead band), thermal storage, better control of CFM/ton, open control APIs (like Chilltrix with Modbus), desuperheaters, better pan/crankcase heaters, better defrost, etc.

Since the heat from the basement want to rise consider turning off the other 2 units see if it can’t do the whole place when it is not very cold. If your insulation and air sealing are good things will tend to be about the same temp all over.

Walta

Good idea, i'll give it a try

Since you have the system instrumented, it would be great if you could run a couple of test to fill in some of the gaps on how these operate. Information from manufacturers is non-existent on this topic.

It would be great to see power trace of operating each head individually by first setting the units to max heat and slowly brining the setpoint down. If you have a decent temperature gauge (digital meat thermometer works), you can measure the delta T across the unit to see its output.

For example, the 9000BTU head has 25F delta between intake and exhaust and is running at high speed (320CFM) it would be putting out 320*25*1.08=8640 BTU. Combined with power readings, this would give you a rough idea of the COP of the setup.

Most likely the COP with only the 9K head running will be low as the head is bellow the min modulation of the outdoor unit and there will be refrigerant bypass through the other zones.

That would be interesting to test. If you help walk me through it I'll give it a try. I have a bunch of these temperatures loggers (https://shoponset.hoskin.ca/collections/temperature/products/hobo-water-temperature-pro-v2-data-logger?variant=42959145936) that I typically use underwater but they work well any where and could be useful. I can set them to log temperature down to every second depending on the frequency needed. Turn two of the units off, turn the remaining unit to a very high set point and high fan setting so it is working as hard as it can (does it matter how long?), temp loggers located at input and output, start decreasing set point until it stops putting out heat. Compare kwh energy used from electrical monitoring to the BTU calc above? Repeat for other units. Will the COP change as the set point gets decreased or will it go full blast unit that set point is met?

Your steps are exactly what I was thinking. Maybe add in the outside temperature as a refence.

Mine (LG) seems to stabilize in about 1 minute of run time, as long as you are not driving the family out of the house by overheating the place, a longer runtime might show more.

P.S. If you look at the specs of your outdoor unit:

https://ashp.neep.org/#!/product/31981

It has a 150W pan heater. From the description there, the controls for it seem to be pretty dumb. This means it is running pretty much all the time when bellow freezing. The base load you are probably seeing is this plus the compressor heater and fans in the indoor units. If the description is correct, this is a giant failure on Mitsubishi's part for having such terrible control logic on a pretty big power hog. 150W over a month is a lot of wasted energy.

I'll give that test a try this weekend and see what I can come up with. It looks like we will be around the freezing mark at night and up to 15C during the day so it might provide a chance to test at a few outdoor temperatures.

That is a lot of energy. It seems to be running the pan heater above freezing as well. I'm not sure what the cutoff is, but we were up to 39F yesterday and it still appeared to be on.

The energy that is needlessly wasted by the pan heater is why I eliminated the Mitsubishi MUZ-FH12NAH as a potential replacement for one of our two ductless mini-splits, and have chosen the Ouellet UHD12 instead; in our climate, that pan heater would have consumed upwards of 500 kWh of electricity ― $80.00 a year at current rates ― beyond what would have been required otherwise. The Ouellet is more energy efficient (14.0 HSPF/30.5 SEER versus 11.5/26.1), and maintains 100 per cent of its nominal heating capacity at -15°C and 80 per cent at -30°C. It's also a lot less costly, and for a small additional charge, I can purchase an extended ten year warranty that covers both parts and labour, well worth it for the peace of mind alone.

Our Sanyo, which doesn't have a pan heater, draws 15-watts when turned off and 35-watts whenever the compressor heater kicks on, as per the graph below.

Interesting, and good to know. Do you manually have to make sure no ice jams build up in the winter or is that not a problem?

I hadn't heard of the brand before. Is it hard to find install/repair help or is it more of a DIY version?

> Ouellet UHD12

Which appears to be a re-branded Gree.

As Jon pointed out below your unit appears to be a rebadged Gree. I have a 12k Gree Sapphire split with an electricity monitor on it. In fact the specs of your unit look identical to mine. I can confirm the base pan heater only comes on during a defrost cycle. I also have a Midea that operates the same way as the Gree.

Why would Mitsubishi energize the pan heater outside of a defrost cycle? It's really only needed during one.

@ Akos, when using the CFM*deltaT*1.08, what does the 1.08 value refer to? I have run a test on the 18k one way ceiling cassette but the numbers I come up with are only around 9792 BTU (I think max CFM is 403 for this unit and I got a deltaT around 22F on average). Given how much energy is being used, this results in a poor COP score (that I hope is incorrect). It does seem a bit tricky figuring out what values to use for electrical monitoring. Despite being set to 29C to try to ensure max output (at 8:02 on attached picture), it takes quite a while and multiple 'steps' before it seems to get to max kW yet deltaT was near the max well before that. At 8:15 I started turning it down. I tried calculations based on the average of the 15 minute test as well as two minutes it was running at its highest input. In both situations, COP was very low, and numbers just didn't seem right. The other two units were turned off and I had temperature monitors on them. They didn't not appear to be bleeding any heat based on the temperature loggers.

I've also played around with estimating COP based on daily ASHP energy use, average daily temperature, and estimated house load assuming there is a linear relationship between temperature and house heat load. This would be easier if I had more confidence in what my house heat load was but I have run a few scenarios (e.g 25k, 30k, 35k, and 45k). I suspect I am in the 30-35k area but the COP numbers seem a bit low for most days based on that assumption and their rates specs on ASHP site. The most comprehensive energy assessment I had (through Natural Resources Canada) came up with 55K @ design temp but if that were true my unit would be running at COPs above what it is listed at.

What I have so far:

Date ASHP daily kwh Average Temp C COP30K COP 35k COP45k

April 18 2021 14.2 8.8 3.43 4.00 5.15

April 20 2021 24.5 2 3.41 3.98 5.12

April 21 2021 37.9 0.9 2.35 2.75 3.53

April 22 2021 36.6 1 2.42 2.83 3.64

April 23 2021 18.4 7.6 2.98 3.48 4.48

April 24 2021 7.49 10.1 5.62 6.56 8.42

There is likely some error here especially as it gets warmer as there is probably a solar assist occuring.

1.08 is the specific heat capacity of a cubit foot of air at standard conditions, that is the amount of BTUs it takes to heat a cubic foot of air up by 1F.

You should be seeing higher delta T across the unit. It takes a while for the temperature to stabilize, should be closer to 35F to 40F. Could also be where your sensor is located, try to get it right into the outlet of the unit. The outlet temprature is also limited by how hot the room is, if the intake air is too hot, it won't be able to raise it a lot especially when it is colder outside.

The compressor ramp up is a normal, a bit surprised to see it get up to max power. Usually these only get up to max power during defrost. With the 18000BTU head, it should have been running around 1.8kW.

You can try to let it run a bit longer at the setpoint and wait for the power to somewhat stabilize.

> Most likely the COP ... will be low ... will be refrigerant bypass through the other zones.

But it's highly likely that the heat in the other zones will be useful. So probably should be included in the COP.

True. I don't think I could measure air flow out of the units that aren't running at a set speed (unless they do when they are just dumping excess heat?), but I could have a temperature logger on all of them (input and output) regardless if they are the one being tested to see the deltaT at the others. It does seem like even if just the big 18k unit is calling for heat, I still feel a little bit coming out of the other two despite being over its lowest modulation (or maybe it isn't, not sure specs for heating of 18K but outside unit is 45K). Could be close. Doesn't seem to be enough to throw off set points for my system compared to excess that comes off the 9K.

Hi Dan,

I'm unable to reply to post #25, so I'll answer your questions here if I may. I keep an eye on the outdoor units whenever we experience an extended cold snap or bouts of freezing rain, but, for the most part, ice accumulation hasn't been an issue. The odd time when I do see ice build-up in the pans, I boil a kettle of water and pour in the tray, and that takes quick care of it.

Hopefully someone will correct me if I'm wrong, but I believe the Ouellet is a rebranded Midea, and they're only sold through authorized distributors/installers.

Correction: Jon tells us it's a rebranded Gree.

@PBP1 - thanks for the link, those numbers are great to see and I will look back at them as I get more information. Given your unit is likely a bit more closely sized to heat loss, and your house is tigher/better insulated than mine, I am fairly certain we will be above your numbers, but how much will be interesting. It is possible our heat loss numbers are a bit higher than I am thinking if yours are close to 30k. Our house envelope has improved a lot, but it is still a 1965 build and there are certain limitations to our improvement (basement floor). We have gone from about 7 ACH50 to 3.8 plus a number of insulation improvements, window replacements etc., but I am not sure if we can get too much further for reasonable investments. Our house is 2250 sq ft split between the main level and basement. The basement includes 300 sq ft of crawlspace (R20 on walls, R10 on floor), 700 sq ft of original (a mix of R10 - R20 depending on access on walls and R0 for floors, and a small 125 sq ft addition (R20 on walls, R10 underfloor). Main level is the original 2x4 walls with 2" rigid foam added, R60 in 2/3 of the ceiling and 1/3 is a cathedral ceiling with ~R20. I'd love to get the ACH50 lower but I am running out of places to look.

Why does the power appear to slowly ramp up to a peak? Is the compressor really modulating up from zero?

I've added a few more pictures that are zoomed in and better show what is happening. It seems like it often starts off around 250W goes up quick then back down again and repeats every 5-10 minutes. When it was warmer a couple days ago, it would come down from ~250W to ~50W when there was longer times between calling for heat, but never 0. I think the fan in the ceiling cassette is usually running so this may be the 50W? I can't make sense of it but don't really understand it. I thought they had more modulation and didn't realize the indoor units were full on or off. That makes it less clear (to me) what is happening around 07:00 in the April21_0600.jpg

I agree that some controlled tests with a single head (say 18K) would be easier to analyze. It looks like it is often ramping up compressor speed (after about 8 min) when it could meet the heating needs by maintaining lower compressor output for a longer period. Which might result in slightly better efficiency.

Would nice to know if a head is actually fixed output, or can vary with compressor output and fan speed.

A 200W floor might be a heater?

Good point, I wonder why that is. The only thing I am thinking of doing to possibly help that is using the remote temperature sensor for the ceiling cassette. It is at one end of a 750 sq ft room blowing towards the other side with quite a few windows behind it. I wonder with it blowing the heat away and cold air coming off the windows nearer to the input if this causing it to act a bit funny. It seems to be doing most of the work and I don't think the ducted unit with M1K1 has that same ramping up pattern at the end. For the size of the room, I have trouble believing the 5 minute run times are changing that rooms temperature enough to shut it down again. It does keep the room very consistent though, so maybe this is just normal. First ASHP for me, so it is all new, just expected longer run times.

Thanks Akos. I did another test it seemed to stabilize a bit better. I got as high as a deltaT = 27 (97-70). It doesn't seem to want to get over 100F but maybe I haven't let it try in the right conditions. Given I am already at 70F when trying, maybe a higher deltaT would be achieved if the test was started at 60F. This unit does have the longest refrigerant lines, hopefully that isn't a factor. The outdoor unit is about 15 feet from the branch box and this unit is 50' from the branch box.