Frost Protected Shallow Foundation in Northern Wisconsin

I’ve long been intending to rely on a basement foundation for our single floor house build but, after reading Scott Gibson’s article on where to put my stuff, I am questioning that plan.

https://www.greenbuildingadvisor.com/article/where-do-i-put-all-my-extra-stuff?source=W20004EN&tp=i-1NHD-BC-GYU-1BN9Hr-1o-5fxw-1c-rs3-o3kwf-l51e1BwSEM-1HBFOm&sourcekey=W20004EN&utm_campaign=green-building-advisor-prime_eletter&utm_source=eletter&utm_medium=eletter&utm_content=gba_prime_eletter&cid=63642&mid=1084189775

The truth is that we need some of the storage provided by the basement, but a single floor 1,764 sf design left us with a massive basement that I’ve always looked at questioning how we would use it.

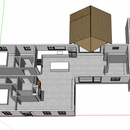

I’ve moved our original 30×36′ design to a 30’x40′ design in order to incorporate a centrally located utility closet and I believe that the home storage and attached garage will provide enough storage for our needs.

I’ve reviewed the FPSF details and understand how this would be executed. A few questions:

1. Considering that my site drops 30″ from the back to front, is FPSF out of the question or do I just build up grade at the front of the house?

2. Is there anything about the attached design (ie: it is not a single rectangle) that would make a FPSF inadequate for the foundation? It spans 110′ from the master on the left to the garage on the right. Grade is flat in that direction

3. Are there concerns with the mechanical room being located in the center of the house with no exterior wall? How would this house with a mono slab run air exchange ducts and other mechanicals?

4. How would we do wood and tile floors (and keep them flush with each other) above a monolithic slab? I’d prefer if we didn’t have to build up a whole wood and foam subfloor to lay wood floor so that we could keep tile and wood floor flush.

Thank you for your feedback!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

There are proponents of PGH who aren't a fan of basements, but it's an arguable point. I find those proponents are often architects who, in my opinion, veer towards over specializing a home, eliminating a lot of the flex space that allow uses to adapt over long periods of time. The elimination of basements is an excellent example: If a space can't be used for it's 'highest and best use' (because it might have a moisture issue, etc.) then try to design it out. This ignores that a basement doesn't need to be finished, and is an excellent way to increase the size of the conditioned envelope at a lower cost when compared to building a larger framed structure.

Just think about how many families have benefited from having basements over the last six months - a perfect place to stick a temporary home office or work out space, or just provide some minimal furnishings for the teenagers in the family to 'get away' from the main areas of the home.

To address some of your questions:

I am not a structural engineer, however, the Wisconsin code does not indicate that rectangular vs non-rectangular is an issue regarding FPSF. They actually provide some decent guidelines for insulation placement in the appendix for these types of foundations. Take a look if you haven't already, so you'll know what the inspector is expecting to see in your details. If you don't want to build up to accommodate the 30" drop, a frost wall with captured slab might be an option worth considering (split the concrete savings difference between FPSF and a full basement pour).

Regarding the utility room, I built a FPSF single family home for a client back in 2014 where utilities became an issue. It was a cathedral roof structure, so no basement and no attic. And it was a stick framed second floor deck, so there wasn't even a nice web truss to pass stuff through. We had to set a bunch of the plumbing and some of the electric into the slab before the pour, and the second floor HVAC (ducted minisplit) ended up going in a false attic above a second floor bedroom - barely accessible for servicing. Not having a conditioned attic or basement is going to make your utility design difficult, and important to plan out from the beginning.

My experience was bad enough on that 2014 house that when I work on one in 2016 with similar restrictions (no attic, wide open floor plan, and no basement although this time it was due to being pinned to ledge with only a unconditioned crawlspace available) both floor decks got framed with webbed trusses even though we didn't need them for the spans. It made utilities a lot more possible, although still difficult.

I'm a fan (and promoter) of the Pretty Good House approach and advise against basements and crawlspaces, except when they make sense. Every project is different. It sounds like you probably don't need a basement, so why go through the expense and hassle to create a space that may or may not perform as intended?

1. Considering that my site drops 30″ from the back to front, is FPSF out of the question or do I just build up grade at the front of the house?

You can still do a FPSF but on sloped lots I recommend using a raised slab detail, with separate pours for the perimeter wall and the slab. (Or go with a concrete-free slab: https://www.greenbuildingadvisor.com/article/minimizing-concrete-in-a-slab-on-grade-home.) I have had projects where enough fill was brought in to allow a mono-pour, but it was a LOT of fill. You could price it out both ways.

2. Is there anything about the attached design (ie: it is not a single rectangle) that would make a FPSF inadequate for the foundation? It spans 110′ from the master on the left to the garage on the right. Grade is flat in that direction

As Sam noted, there are prescriptive recommendations in building codes for how to handle corners. Unheated garages introduce some complications to FSPSs.

3. Are there concerns with the mechanical room being located in the center of the house with no exterior wall? How would this house with a mono slab run air exchange ducts and other mechanicals?

Most high-performance builders are aiming for all-electric homes; if you don't have combustion appliances that need to vent to the exterior, you should be able to use an internal mechanical room. I've had HRVs that are 30' from the exterior wall, but it's far from ideal--if possible, change the location of the mechanical room, or at least the HRV.

4. How would we do wood and tile floors (and keep them flush with each other) above a monolithic slab? I’d prefer if we didn’t have to build up a whole wood and foam subfloor to lay wood floor so that we could keep tile and wood floor flush.

If you want wood and tile floors, there is no need for a concrete floor also. If for some reason you insist on a concrete floor under your finished floors, you can cover the entire concrete floor with 3/4" subfloor and install the other materials conventionally (using short nails for the wood floor).

For wood flooring, today there are engineered floating hardwood floors that require no nailing or gluing, and have several advantages over the "old school" traditional wood floors:

1. Much easier and faster to install. Roll out their underlayment, then wood flooring planks click together. MUCH better option for consumers to do it themselves.

2. No finishing required, typically are prefinished (and you also could buy more traditional strip flooring pre-finished, just not the traditional wood flooring). Install rolls of underlayment, then the planks, and you are done except for baseboards on walls, thresholds at doorways etc. (which need to be done with traditional nailed or glued wood flooring too). Installs very quickly, especially large open areas.

3. You can remove the engineered flooring by reversing the process of installation, then re-install elsewhere; or replace some damaged area more easily.

4. Engineered wood flooring doesn't expand and contract like the old stuff, as it is manufactured with several layers with grain of the wood perpendicular in each layer, like plywood.

One disadvantage is that you can only refinish the floors fewer times. Normally the finish layer allows it to be refinished 2-3 times. Typically you don't expect that to be needed often in residential flooring. If a small area needs refinishing, its easier to replace that area anyway.

Just buy better quality engineered flooring (e.g., Kahrs) not most of the junk sold at big box stores. $5/SQFT typical, plus underlayment, shipping. taxes. Wide variety of wood species and styles are available.

Note that you can do the same with tile. Luxury Vinyl Tile (LVT) or Plank (LVP) goes on the exact same way. You can get it from the same supplier as engineered wood flooring. Same advantages. Even less labor, vs. installing using thinset and grout on traditional tile. A lot less messy install too, without needing the tools and cleanup required with traditional tile.

I can't believe people haven't all switched over to these newer products. You can install engineered hardwood or LVT/LVP over existing floors if they provide a flat surface.

I built one in central WI last year, 30” of grade change over 110’ is nothing that cant be dealt with.

I worked with the inspector using a design guide book for submittals, and I built a sealed chase down the center of the house for ducts to avoid duct sealing and duct pressure testing. I tested it at under 2 ach50 when it was all said and done, I didnt do any extensive air sealing at all with it, it was a spec on a nonconforming lot.

Floor elevation changes would be tough, if you wanted certain areas higher I would wait until all framing was done, then use a top coat product to raise the areas you want higher.