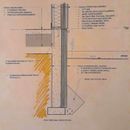

Foundation detail

I’ve been developing my “poor man’s thermomass” for some while and hope to get some feedback on a few points. First of all, after looking at many many many other foundation details with exterior insulation, I’m still not confident that this arrangement of insulation sufficiently creates a thermal break. Most discussion is about insulated basements but this is slab on grade.

Below 4″ slab is 10″ recycled glass Poraver beads. This is on top of compacted gravel. At the Endeavor Center, they put 6mil poly below poraver. I’m worried this created a “bathtub” situation.

Also, is insulation outboard of stem wall sufficient, or do I need foam under the footing?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I meant:MOST discussion is about insulated basements... This is slab on grade but due to site constraints I can't do raft slab or FPSF.

Ethan,

Why are you using foam to insulate the foundation wall, rather than under the slab and thermal mass?

Well it's Rock wool. I put it outside to maintain the plane with the wall. Sub slab is poraver beads. So stem wall insulation should be on the inside of the wall?

Ethan,

Below is a detail showing the usual way to insulate a slab on grade with stemwalls. For more information on standard advice, see this article: Insulating a Slab on Grade.

Of course, you can always deviate from standard advice, and come up with your own details. I can't think of a good reason to use Poraver beads to insulate a slab, but I'm sure you have your reasons.

The polyethylene layer always belongs directly under the concrete, with no intervening insulation, for the reason you mentioned. Here is a link to an article with more on that issue: Polyethylene Under Concrete Slabs.

You don't need insulation under your stemwall footing.

.

Martin, thank you, I have seen that detail at FineHomeBuilding, or maybe here. A couple things... One, as you can see in the detail I posted, I have 4" of continuous Roxul outboard of my 2x6 framing, so I have read elsewhere that it can be advantageous to continue that to the foundation wall in order to simplify detailing. Maybe I'm wrong. In the detail you post there seems to be a real thermal bridge at the sill plate. Also, creating the edge of the slab effectively in the detail you post with 4" of Roxul around the perimeter seems to pose a problem. Lastly, my reasoning for Poraver is it is recycled glass and very inexpensive. Also, pouring it all out at once into a flat subslab seems easier than piecing a whole bunch of foam together. Also, in the interest of Green Buildling, Poraver is "not foam."

Ethan,

Sorry, that was lazy of me - I assumed Poraver glass beads must be added thermal mass of some sort, not insulation.

Detailing exterior insulation is typically harder than interior because it needs mechanical protection between the bottom of the siding and grade. It also uses a lot more insulation to cover the wall right down to the footing. Something you don't need on the inside.

Malcolm, don't worry I'm used to people not looking at details ;). You write "It also uses a lot more insulation to cover the wall right down to the footing. Something you don't need on the inside" but in the detail Martin posted the insulation runs down the inside of the foundation wall all the way to the footing... seems like the same quantity just in a different location. That being said, if I can figure out how to minimize the thermal break at the sill, it does seem a lot easier to build if I move the insulation inboard of the foundation stem wall. Another Advantage seems to be that it will be compressed by backfill and not have a tendency to fall off the sides during construction.

So I built a therm model of the inboard and outboard insulation configurations. Trying to keep all else equal, and trying to in some way replicate the detail posted by Martin, it seems to me that the performance of the outboard insulation is significantly better. This is evident on the Temp and Flux outputs. This is more of an anecdotal comparison, but there seems to be some real performance advantage to outboard insulation.

Ethan,

For what it's worth, here's what I'd do.

- Move your stud-wall in so that it cantilevers over the interior of the concrete foundation wall by 2", and one of your exterior layers of insulation sits on the concrete. This allows you to thicken the insulation between the foundation wall and the slab, while still covering it with the wall above. It also lessens the area of thermal bridging at the sill plate.

- Eliminate any insulation on the exterior or interior of the foundation walls and beef up the insulation under the slab.

Malcolm. I appreciate your idea... I am loathe to cantilever my framing, as I believe it will destabilize my entire framing scheme. For reasons which are less obvious in this simple 2D THERM model (stepped foundation, 15% slope site) I am going to stick with my exterior insulation scheme (protected by concrete board). I will continue to develop the THERM model to figure out an ideal depth of the insulation as I don't see that it needs to go all the way to the footing.

Ethan,

It was just a thought. Of course do what you are comfortable with, but I'm not sure why you would worry about cantilevering the 2"x6" when they still would have 3 1/2" bearing.

My primary point was that the 4" of exterior insulation continuing right down to your footings isn't doing half as much as the same amount of insulation placed under the slab.

Ethan,

When you're comparing your interior and exterior Therm models, and your Therm models of different depths to decide which is "better" you might benefit from setting some specific performance goals.

Is your goal to ensure that you have no condensation risks at that interior corner between the wall and floor? Figure out what temp you need to hit in that corner, and then the simplest/cheapest detail that hits that temperature is the best. If the interior insulation is good enough (and is indeed easier, which it may or may not be depending on your other requirements), then despite the Therm model of the exterior insulation "looking better", the value of that corner being a little bit warmer is probably pretty far into diminishing returns.

Same goes for thermal bridging and energy use. You can calculate the linear thermal conductivity of the detail with Therm (psi-value). You can either set a psi-value target, or convert it into energy lost per year, and set a target that way (perhaps in dollars). For example, PHIUS considers a thermal bridge with a psi-value of less that 0.01 W/mK to be negligible. So if your detail is below that value, then you're good to go, and again, hitting an even better value is probably well past the point of diminishing returns.

I guess what I'm trying to say is, it's worth taking Therm a step further and using its analytical capabilities, in addition to the general visual information it gives you. And don't let the perfect be the enemy of the good :)

Brendan, thanks so much for your insight. You are right that it is easy to get caught up in perfecting the isotherms rather than looking at performance. I have been unable to figure out how to calculate the linear thermal conductivity in THERM, so that is something I have to dive into. I have also been unable to get it to display "condensation potential" though the option to do so is right there.

One aspect of this design that does not come across is that it is basically a stepped foundation and functions much like a "walk out basement." The reason I have been reluctant to move the insulation inside the foundation wall is that as we move up the slope, the interior of the foundation wall will become the interior of the conditioned spaces, and I do not want to encapsulate the entire foundation wall at that point.

I have attached my current three contending details. Now I just have to figure out how to locate the psi-values, energy lost per year, etc.