Foam sandwich

I’ll run this by my architect but thought I’d check here too.

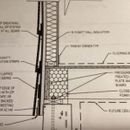

Upcoming project spec has Zip R-6 on an addition over a new basement space and Closed cell spray foam on the interior of the rim all the way around the house. Basement will then be finished.

This creates a situation in the plans where the rim on the addition has Zip R-6 on the outside (little exterior drying potential) and spray foam on the inside (little interior drying). I see this as creating a potential issue. Am I correct here?

I’ll omit the interior foam in the addition area and use Rockwool if I am correct.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You are correct about the limited amount of drying potential with that assembly, but it’s unlikely to be a problem in practice. You should specify the addition of a capillary break between the top of the masonry foundation wall and the sill plate though. You also typically want the spray foam to seal the masonry into the assembly to “wrap” the sill plate to minimize the chance for air leakage.

Without a capillary break the assembly is much more at risk for moisture problems. If you're really worried, you can use EPS panels installed with canned foam around the perimeter in place of spray foam for the rim joist area, but it is a LOT more labor to insulate that way. EPS has the advantage of being the most vapor open of the common rigid foams, so it does allow for a small amount of drying.

Bill

Thanks. Air sealed capillary break at the plate is standard practice for me and is spec’d elsewhere. I also have a detail sealing the bottom of the Zip R to the foundation.