Seeking Opinions on Flex Duct Plan

Hey all, appreciate any experience or insight. I’ve read all of Allison Bailes’s articles on flex. I posted a little about my addition HVAC situation here earlier:

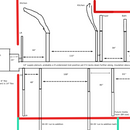

I’ve attached a rough sketch of my HVAC ductwork. Here’s the vital stats on my house:

1. Single family home, 1500 sqft, crawlspace

2. Climate zone 4a

3. Addition on south side, 300sqft (included in 1500sqft overall figure). Poor contractor planning of HVAC, IMO. Two 6″ flex lines run through original foundation into addition, 30-35′ runs. Big comfort issues here (and I am not picky either).

4. I ran a Manual D (I’m an engineer), the branches are basically sized correctly except for the addition. All branches are 6″ flex. But, the supplies and returns look like they should now be 16″ with the addition, vice 14″ installed.

Last post was about #3. Since then I re-routed one of the addition lines with good CFM improvement. I plan on re-running the remaining line to the addition soon, and evaluating performance this winter & next summer. May have to throw in a booster, upgrade to 8″, or go hard duct if it’s not acceptable (or do a minisplit! prefer to stick with one unit though).

I’m also contemplating and prioritizing long-term duct improvements overall, keeping in mind that my package unit is 13 years old and its eventual replacement would be a good time to do any major ducting work (like plenum replacements as necessary).

There’s a number of things I’ve noticed about my current ductwork:

1. All flex is run uncompressed (not tight) and with bad turns. I will eventually sheetmetal elbow all the register boxes and rerun the flex properly, sealing well with mastic.

2. After the 300sqft addition is accounted for, the Manual D goes from 14″ to 16″ supply & return plenum. I have 14’s installed. I have to admit the return is a bit noisy but this could just be return register is undersized. Maybe further investigation necessary here.

3. Two supply runs within 8″ of the plenum endcap. I’ve read this should be more like 24″ from endcap (https://www.rses.org/assets/serviceapplicationmanual/630-148.pdf)

4. If I have a “reducing” plenum (like it goes from 14″ to smaller diameter at some point), some of my supplies probably aren’t 4′ from that transition. But I’m not sure if it reduces yet. I thought it did, but then I looked inside the plenum (through a takeoff hole) and where I initially thought there was a transition, both sides looked the same. More investigation.

I’m trying to prioritize how big of a deal these issues are, looking for any advice. My thought is I can address #1 now, and #2-4 could be addressed when I get a new package unit by also installing new supply and return plenums, allowing full duct redesign.

Right now, based on overall good comfort in the main house (no I haven’t run temperature or pressure measurements between rooms yet, but I’m personally comfortable), I think #3 and #4 probably aren’t worth pursuing unless I get all new ductwork in pursuit of #2. Also my generally intuition is that #2 probably isn’t a huge deal since I’m on the cusp of 14″ being acceptable per Manual D. I haven’t priced out 16″ sheetmetal yet but as with all things, the labor is the worst part (mine or someone else’s).

Any experience or insight is greatly appreciated! I’m not a Passivhaus dude, just looking to improve anything in the “terrible” or “bad” category!

EDIT: I was remiss in mentioning I have a retired friend who generously helps me with HVAC for free (he has been to HVAC school and is in practice). He has a smoke machine, pressure manometers, etc. that I can use for duct diagnostics. I plan on having him help me measure external static pressure at some point. He will also help me install the new package unit when the time comes, though I’m not sure how excited he would be about plenum replacement. I could probably enlist other younger labor for that task though in exchange for top-shelf bourbon and beer.

Thank you,

Eric

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

#1 is likely your biggest issue. Flex duct in a perfect installation is much worse in terms of back pressure and flow restriction compared to rigid duct, but if it's loose and sagging with kinky tight bends, that's even more of a problem. I'd try to replace all that flex duct with rigid duct. In a typical commercial building, flex duct is used only for short runs between the supply plenum and ceiling vents, where there isn't really much choice.

Smaller than optimal ductwork will have a higher air velocity for the same airflow volume. This higher velocity means more flow restriction too. How severe this is in terms of overall system performance impact depends on what the actual delivered air volume is as well as the length of the run. If the undersized run is short, then the total impact will be low. The worst case scenario would be a long run of undersized duct with a high flow volume (such as you'd have if all the vents were at the far end of the undersized duct run). With your distributed system (vents distributed along the length of the run), the impact of the undersized duct diminishes as you get further from the supply. Your biggest issue will be in the first maybe 1/3 to 1/2 of that run. It's hard to say much more without knowing the actual air flows involved (CFM).

#3 and #4 are minimal in terms of overall impact compared to the first two. I wouldn't worry about these unless you're trying to optimize everything to the max.

Bill

Bill, thank you very much for your insights! I won't sweat the small stuff then. Heading down into the crawl for another flex session, it'll go a little quicker the second time around...

Eric