Fixing Air Leakage in Exterior Rigid Foam on Roof Retrofit-Pics Included

I live in Norfolk, VA. 4A Climate zone. About 50 miles south and I will be in Climate zone 3. I live in a 100 year old home.

In the past year I decided to start on a multi year energy retrofit project. One of my first steps was the roof. Based on GBA recommendations, and due to low slope roof I decided on external rigid foam. I hired a consultant, and they put a great design together for me. However, finding a roofer to install was another matter. So the consultants design was not 100% what was able to be completed. Long story short, after the roof has been installed and I have blower door tested, there is still major air leakage from the attic to outside the home. It was difficult to make sure the roofers did the air sealing parts correctly. In their defense, this was probably their first time doing external rigid foam on a residential home, that was not an EPDM roof.

The gable ends are air tight, and the eves are air tight. These two sections I did myself. Also blower door + thermal shows this.

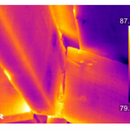

This leads me to believe there is leakage at the ridge beam and possibly through the board sheathing and into the underside of the zip.

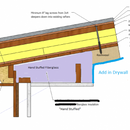

Here is my solution. Is this crazy? Other ideas?

Add essentially a mini knee wall, then drywall the kneewall, and drywall the ceiling after I have added rockwool between the beams. The rest of my home is stripped down to new drywall. Have Aerobarrier come in and spray the house, and make the air barrier the drywall.

Will that space behind the kneewall with “hand stuff fiberglass” be a problem. Will it be able to dry?

Please let me know thoughts. Retrofits seem to encounter many more problems than one would expect.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Why are you considering adding fiberglass if your goal is air sealing? Fiberglass insulation isn't an air barrier...

If you have access to the underside of the ridge, I would try injecting some canned foam along the seam to seal it. If that's where you think the big leak is, the canned foam should take care of it. My guess from that thermal image is that the rigid foam sheets didn't quite line up at the ridge so you have some gaps and/or thin spots up there under the vent. Canned foam should take care of the air sealing part, but you might need a thicker layer if you also want it to help with insulation. You could do the same thing out at the eaves if you have potential leaks there too.

Some smoke stick tests with a blower door running should help you find the air leaks. I'd inject any leaks you find with some canned foam, or use caulk on small seams where canned foam can't penetrate. Canned foam "over the top" of a gap usually isn't reliable long-term, so that's where you want to smear on some caulk. Canned foam works best in gaps where the canned foam can penetrate INSIDE the gap to seal it.

Bill

Thanks for the reply.

"Why are you considering adding fiberglass if your goal is air sealing? Fiberglass insulation isn't an air barrier..."

-The consultant called for drill and fill cellulose. However, I found it difficult to find an insulator that could do it from above. Apparently there is different insurance to put an insulator contractor on top of a roof. There was also the issue of scheduling, so I kind of skipped this step, and shoved in the fiberglass.

"My guess from that thermal image is that the rigid foam sheets didn't quite line up at the ridge so you have some gaps and/or thin spots up there under the vent."

-Your are probably correct on this. The blower door RESNET guy advised me this could be the issue also.

The smoke pencil is a great idea. Thanks

Andy