Exterior rigid insulation in remodel

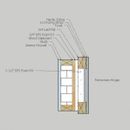

Hi, I have an existing cape cod home with 2×4 walls with 60yr old rockwool in the cavities and 1×8 shiplap on the exterior. I am thinking of trying to do 3/4″ EPS (r3) unfaced on top of shiplap, then 2×4 laid flat at stud locations, then 1-1/2″ EPS (r6) unfaced in the gaps, then Tyvek, then furing strips for a rainscreen then Hardie plank siding. The reason behind EPS is its drying ability and permeability and the fact it doesn’t lose R value over time as much as all the other types. See sketch attached. I live in on the border of climate zone 4 and 5, so according to this article

https://www.greenbuildingadvisor.com/article/calculating-the-minimum-thickness-of-rigid-foam-sheathing

those thicknesses work. At the top and bottom I am going to use Coravent to prevent bugs.

Does anyone see any inherent issues with vapor, or reliability of this wall system? Should the 3/4″ layer of foam be XPS instead so it doesn’t compress as much?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Skip the 2x4s. The labor to cut all that foam in is going to be a problem. I don’t see what the 2x4s accomplish either. Just use two layers of foam with the seams overlapped, then 1x furring over that to give you your rainscreen gap. That’s the usual way to use rigid foam on the exterior.

Bill

EPS can resist compression just as well as XPS if you get the right type; see this resource: https://www.epsindustry.org/building-construction/compressive-strength.

Peter