Electric question

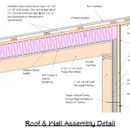

I’m building my own house and will be doing the wiring. My roof rafters will be 4×8 timbers and be exposed (like a log home), so there will be no attic space in the house. I will be running ROMEX down through these rafters for a couple of hanging overhead lights. I will have 8” of rigid insulation that will sit on top of my T&G sheathing, which is then followed by a grid of 2x4s that creates a ventilation gap between the insulation and a metal roof (see attached pic).

Is it best to run the ROMEX on top of my T&G sheathing, directly underneath my weather wrap and insulation? The other option is to run it up through the insulation and then through the ventilation gap just under my metal roof? In both cases, the wire will be basically inaccessible and there will be no junction boxes, it will just be long runs of wire.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Don't route the wiring through & above the roof deck & weather resistant barrier. The fewer number of penetrations the better.

If you can route a channel into the top of the beams sufficient to run conduit for #14 AWG wires (not romex) without impacting structural limits it would be easy to service, and would avoid roof penetrations. Alternatively the conduit could be placed atop the beams, notching the t & g to accommodate it.

Thanks Dana,

Routing a channel in the beams is not optimal in my case. This is because I will be using long screws to fasten my 2x4 lathe grid (what my metal roof will then be fastened to) through my rigid insulation into the 4x8 roof rafters. Given that, the conduit could be in danger of being hit by one of the screws.

I'm really just trying to understand if there are any code violations I should be concerned with. with either of the option I initially mentioned.

You may want to consider putting the wire on top of the beam in steel conduit in a gap in T/G so it would be below the insulation and air barrier. Almost certainly any screw going thru 8 inches of foam will be deflected by the round surface of the conduit.

Be sure to carefully detail your air barrier and consider using 2 4" layers of foam with staggered seams.

Walta

Rodrob15,

One of the things to look out for when deciding where to run the wire are the code requirements for a certain depth of coverage from any surface.

Romex (Type NM) is not permitted in damp or wet locations as per the NEC. It needs to be below the weather resistive barrier. You could use Type UF Cable instead of Romex but then you'd be penetrating the barrier.

Conduit won't work because there's not enough room for the bend radius. If you ran the conduit above the rigid foam you would have the room for the bend but then condensation may form in the conduit and drip down below.

I would use Romex and staple it to the top of the beams running down the center of the beam, either down or up to the closest wall (preferably interior wall). Then, in areas where there is Romex run the T&G right up to each side of the Romex leaving a 3/4" gap between the edges of the T&G.

You could nail 1/2" steel plates above the chase where the Romex is to prevent penetrations from the long screws. Assuming you're not installing Romex on that many beams you can also mark the top of the foam where the beams are so you can drive the screws a little to the left or right to avoid the steel plates.

Your initial plan of running cable on top of sheathing seems the easiest, but I'd discuss your own choice with the electrical inspector before submitting your plan to the building dept. (Or discuss the options you prefer with the inspector if you like more than one option.) Agree that staying below the WRB to avoid penetrations is a priority. I'd consider running conduit in less visible locations and not through sheathing or beams, but obviously not the best aesthetic choice. But easily serviceable and probably not noticed by most people.

I like HarleyDog99's solution except in this case you're going to be screwing 11-12" long screws and trying to miss the metal plates. I would spend the small amount extra and use UF cable above the insulation and drop through (and seal) the envelope for a "couple of" lighting fixtures. Obviously, any solution has to meet the electrical code in your area.

Also, so when you're inside the building looking up you're going to see the 3/4" (best I can read it says 3/4 on the fuzzy drawing) T&G OSB or plywood as the finish layer?

And are your exposed 4x8 rafters 24" OC? If not, will the span meet code for attaching the roof assembly to the structure? I don't think attaching the assembly to the 3/4" sheathing will be acceptable.