Insulating Simpson StrongWall Panels

Hey all,

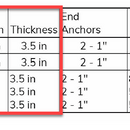

We received our Structural drawings from the P.E. a couple of days ago. The drawings include the addition of Simpson StrongWall (SW) panels to 3 walls. There will be a total of 5 panels, 3.5″ thick spread across the 3 walls. The wall are framed with 5.5″ studs. So, there will be a 1.5 inches cavity in the wall (R10 XPS on the exterior). Panel Schedule Attached. 8 feet in total of width spread across the 3 walls. that is reducing my r-value.

I am looking into ways to keep the R-values up for those walls. I am thinking that using spray foam might provide the highest r-value per inch. Or can I not worry about those sections of the walls where the panels are (I think I know that answers I’ll get for this one)?

Anyone have experience with these SW panels?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

idahobuild,

I've used them, and like them a lot. They are easy to install and integrate into the wood framing. There is a small channel down the middle, and two holes at the bottom which might benefit from some spray foam, but generally they are flat enough that I'm not sure spray foam buys you much that foam board doesn't provide. You will have a 2" cavity to fill, not 1 1/2". That with the exterior foam yields a wall that is pretty good - especially compared to most built up structural posts, which are the full depth of a wall.

Malcolm you make a good point with the post comparison and I will likely have some 2" foam board from the exterior. Then, to your point, I can use spray foam at the bottom anchors and in the middle.

Does the man. J have to account for this difference -- 8 feet is about 3 percent of the dwellings perimeter. I think that I heard somewhere that the Man J calc includes an allowance of about 25% for stud wall. Will we have to re-accomplish the Man. J?

idahobuild,

No. The difference in the R-values between where the shear-walls are and the cavities in the rest of the walls isn't large enough to make a difference when they are only 3% - and the 25% in the manual J is pretty generous.

Great. Thanks again!

The highest R per inch rigid foam is polyisocyanurate, at somewhere around R-5 to R-6 per inch, depending on product, age and temperature. XPS is sold as R-5/in but it ages to about R-4.2/in. EPS is around R-4/in. GPS is around R-4.8/in. I'd use polyiso to keep the R-value as high as you can, but otherwise I wouldn't worry about it.

Great idea Michael M., for the small amount area it does make sense to use a product that 'ages' better than xps.

Also, in looking more closely at the structural plans there are only two dwelling walls that are StrongWalls (B-1 & F-1 in table atch'd above). Each of those walls is only 1 - 18" SW panel. So, it looks like we're only about 3' of cavity loss (+/- the extra framing around the panels -- not sure on that one).

Thanks.