Sizing Ducts and Plenum Layout for Ducted Minisplit

After struggling to teach myself Manual D, I thought it best to just ask folks who understand it all better than I ever will.

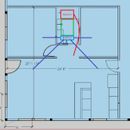

Central TX. We built a metal building, 2″ CCF on the walls, and will add fiberglass batts in the walls as well. Looking at an 18000 BTU ducted mini split for the 650sf of apartment. The way I was planning to install the system basically had a plenum and then ALL straight rigid duct to the ceiling registers. The two the livingroom (12×25′) will be about 9-10ft long and come right out the front of the plenum (in line with the blower). Then the two runs to the bedrooms will be 6-8ft and out the sides of the plenum. Imagine a stick figure person with HVAC at the head, bedrooms branches are the arms, livingroom the legs.

With 450CFM (medium speed), minimal fittings and no bends/turns past the plenum, how much design do I really need? I’ve got all the space in the world, do just build big/low pressure loss (8″ ducts, nice big plenum, 20×20 filter,etc).

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

18000 btu seems excessive for 650 sq ft. If you use a Fujitsu slim ducted RLF series I would recommend the 12k btu. They both actually produce well over the rates BTU especially in heating, the 9k might even 9k might even work. You would need to do a detailed Manual J load calculation. I know the Fujitsu all modulate down to 3100 btu, but the 9 or 12 are more efficient by having better airflow in relation to the size of the case. The 18k tries to move 650 cfm through the same case as the 12k. There is a guy here in Redding CA using the 9k Fujitsu for a 2500 sq fr very well built house. I would also recommend a 20x30 filter. Ducted minis are very affected by any static pressure

I would 2nd David's sizing recommendation. The only time I've had a 9k unit run full tilt in a small apartment is when there was a 7' x 8' hole cut into the wall to the attic, even then it kept the place pretty comfortable.

I usually use a length of 8x12 duct with end caps as the plenum. At the flow rate of most ducted units, the velocity is low enough that the sharp bends won't add too much loss at the flow rate for a bedroom. Make sure you put some dampers on the ducts to be able to properly adjust the flow when commissioning.

I would also consider flipping the unit around so the intake is directly from the living space. This makes the outlet ducting a bit more convoluted and you have to upsize the feeds the living space because of the extra bends, but it saves making an intake duct.

You can then use one of the 12x36 or 9x36 filter grills on the intake.

Used an online manual J and it's spitting out 14k-16k. Since I'd like to stick to just one air handler, it looks like 18k is the way to go.

This is a building inside a building, with the 650sf apartment being in the corner of the larger 1650sf metal building. I had planned a second mini split for the shop side of the building, but I suppose I could get a second head only and divide the load. The shop side is less tight with roll up doors and no Batts in the walls (just 2"ccf). So perhaps a 24k split between two 12k units. I don't need the shop to be all the time comfortable, just take the edge off and humidity control.

For ducting, I put the return on the back side so all the duct runs could be straight. If lowering the static on the return side is more important, I can flip it. Alternatively, the scale is way off and I have tons of space up, I can put the return plenum basically under the unit. And I'm game for a wicked big filter, so 20x30 is totally doable. I saw the articles on dropping that pressure as much as possible.

Multi splits are very hard to get right, you are almost always better off with dedicated outdoor unit for each indoor unit.

The minimum capacity on a 9k and 18k unit is not that different, so except for more cost and larger ducts, oversizing in this case won't hurt much.

With something that is well air sealed with closed cell SPF, the man J is definitely wrong, there is no way the cooling load is that much, I'm cooling a 900 sqft double brick no insulation apartment with 6k, not as warm as Texas but summers do get pretty muggy up here.

It doesn't matter where the restriction is, my suggestion was mostly for build simplicity. You have to make a supply plenum and ducts, if there are have a couple of extra bends in them, it doesn't add that much work. With the unit flipped, you can then avoid making an intake plenum and just use a simple filter (see attached).

I think a typical problem with an online manual J is they over estimate the ventilation air load, and air infiltration loads. That would be especially true on a small space, where small surface area make up a small part of the load. Do either of your 2 walls with windows face West? If so, minimize West facing windows to dramatically reduce A/C load. For ventilation, how are you bringing in fresh air? You have to be very careful if using exhaust only, and while using kitchen or bath exhaust fans, not to bring in shop air from the shared walls of the shop. Air sealing is always the best bang for buck to reduce heating load, but in this case, really concentrate on sealing the shared walls with shop. ccSPF seals cavities very well, but make sure to seal bottom plates to concrete and any wire or plumbing penetrations. The Fujitsu 9RLFCD ducted mini puts out 3100-12,000 btu cooling and 3100-18,000 btu heating, I can’t imagine that not being enough.

I just read Akos last reply. Yes, like he said doing multi splits, 2 indoor units on one outdoor unit, limits the range the units can modulate down to for minimum output and lowers efficiency. I think a Separate 1 ton ductless system in the shop area would do what you are looking for there.

Ok, so perhaps we go down to the 12k fuji unit, flipped so the return is just a 20x30(ish) filter and the ducts have a single big sweeping bend before heading to the rooms.

The apartment portion could get nice and tight, the shop not so much with the roll up doors. The interior (shop/apartment) walls will all get as much insulation as I can squeeze in plus probably a plastic barrier. While there is no intention to store fuel or run vehicles in the garage, it will happen so air sealing those two spaces is important.

One thought on the 12k vs 18k is the CFM from the unit. the 18k putting out more CFM means more air moving into the rooms which in my experience is more important than colder low flow air.

Yes, you need good airflow, but a big part of that is the actual velocity of the air leaving a register. You want 500-700 FPM at the supply grille so it makes it across the room to mix the room air. That would be a 6” duct with a 6”x6” grille or 6”x8” grille and boot for 100-120 cfm to each of 4 registers. Or a 7” duct for 160-180cfm per 6”x8” boot and register. Throw and velocity make a big difference on small right sized systems. The registers Can’t Be stamped cheap registers. Use TruAire 301a curved blade for ceiling mount. Use a Shoemaker 900FG2 or 905 TFG 20x30” return grille with 2” thick filter. If you use the 9RLFCD with less than .2 total static pressure, because of a great duct system, you will be happy with it. The 12RLFCD actually only puts out 1600 btu more than the 9, and 30cfm more. The SEER, EER, and Hspf all drop as you go up in size.

Is Central Texas humid? If so definitely don’t use plastic or poly vapor Barrier in your walls behind the Sheetrock, not even if the drier part of Texas. Possibly use a vapor Retarder, like Intello, to help air sealing, but if any moisture from outside gets past the ccSPF in cooling season, it will drive inwards towards your drier interior air, and condense on a vapor Barrier.

What are your ventilation plans? Exhaust fans? HRV/ERV? If exhaust fans only, it will depressurize the house and besides worrying about the shared wall of the shop for contaminates coming in, also worry about moisture getting pulled in with humid air. Since it’s small and you’re building tight.

When we had our HVAC replaced on our main house they installed fully adjustable curved blade registers, such a huge improvement and so much quieter. So yeah, we are sold on using them.

For humidity, we back up to a really cool wooded canyon which during some times of year is like living in a cloud, so we got lots of vapor. That said, once the sun comes up it burns off fast and it feels awful dry out here. In the summer it is very dry.

For vapor retarder, the walls will be standard 2x4, with DW on both sides and some batt insulation. If I use pink, paper back, does the paper stapled to stud and taped/floated DW get me enough vapor barrier? Or should I also install the Intello or Certainteed MemBrain? Which side of the wall/insulation does it go on (apartment or shop)?

Was just starting to plan ventilation. Will have a down draft vent for the stove and a vent for the bathroom, but keen to add anything recommend. The shop has lots of air leaks with a 10x10 roll up and a standard two car garage door. But the apartment should be pretty tight.

I would recommend using one of the spot ERVs (pair of Lunos fans or Pansonic WhisperComfort) for the apartment. They are not much more than a quality bathroom fan and give you continuous ventilation with energy recovery.

For the garage, it would be good to add some exhaust only ventilation. With big leaky garage doors it is sometimes futile, but if possible, creating a slight bit of negative pressure in the garage space will keep fumes from getting into the apartment.

For vapor control, craft faced batts are good enough, you should not need anything fancy. Definitely no 6 mil poly anywhere.

Minisplit ordered.

Akos, you mentioned - "spot ERVs (pair of Lunos fans or Pansonic WhisperComfort) for the apartment"

Would you go that route instead of the larger ERV from Panasonic. Certainly the Whispercomfort combined with the Pana Recessed vent in the bathroom would come in a few $100 less than just the big Panasonic ERV.

It is hard to say. In warm climate, the ROI on a better ERV is probably never. If the spot ERV has enough capacity for your place, it is a significantly cheaper install even if the price between the units is not that large.

Make sure to get all the Panasonic bits and pieces as well, the tandem hood is a much quicker install.

Akos, for the tandem hood, would you abide by Mitsubishi's suggestion of not exceeding 50 cfm when the tandem hood is being used? Or do you think it can handle higher CFM than that?

Aun,

Not sure what Mitsubishi part you are referring to. The Panasonic tandem hood is for their whispercomfort ERV with is only 40CFM, so not much flow.

The intellibalance unit also lists the same tandem wall cap, which means it is good enough for the 100CFM rating of the unit.

Lifebreath sells a slightly larger dual wall cap that is rated for 110CFM.

> Throw and velocity make a big difference on small right sized systems.

I'm curious if you have data to support this in the case of well sealed/insulated buildings? Eg, across the room temperature difference data with and without good throw.

PG&E here in California does a lot of case studies on test homes, some brand new, some 50 years old, and some 70 years old with air sealing and insulation retrofits. They pre test the houses with existing HVAC, then perform improvements to the existing HVAC, then swap to right sized central units, or even ductless minisplits in the retrofitted 1950 house (it needed transfer fans added to keep temps within 3 degrees). They monitor everything.

They provide free home performance and HVAC classes using these case studies along with case studies from the instructors who also own home performance businesses. I have data from several books from those classes, and have used the information to design duct systems. My go to is either Optimizing Residential HVAC System Performance by Dan Perunko of Balance Point Home Performance and contributions by Mike Macfarland of Energy Docs, who built a 2500 sq ft home with a single 9RLFCD and a 68 degree set point in 110 degree Redding, CA. My other is Residential Air Balancing for Dry Climates by Gary Wollin of Wollin Group.

In such a small space as the bedrooms heating airflow might not matter but cooling might. But in the 12’x25’ living room/kitchen space it would be more important. The goal is for the air to leave the grille face at 500-700 fpm then slow to 50 fpm as it hits the wall across the room, using the grille manufacturer engineering data to choose the grille size. There is more to sizing the ducts for fpm based on whether they are in conditioned space, or a hot attic also. These should be goals to guarantee good room air mixing and no stratification or temperature differences, but in a well sealed and insulated small single story home, they are just goals to try for.

If he uses the 9RLFCD with 4 supplies and only about 380 cfm total, and you’re designing a duct system for low airflow of small right sized systems, I would try to get close to those numbers.

With 3 rooms, I expect that you only need 3 supply ducts.

You may find this article interesting.

https://www.energyvanguard.com/blog/air-conditioner-sizing-rules-of-thumb-must-die

But if we do apply the square feet per ton you manual J falls well below a rule of thumb I ever heard of anyone ever using for the most poorly insulated and sealed buildings.

I put you project on this graph from the article you are the red dot in the lower left corner.

My guess is there are big errors in your manual J calculation is off by 300% if you have R30 walls and ceiling.

Walta

Walter, Thanks for the link. I am happy to send a copy of our Manual J. It was done with Wrightsoft. What the designer found was that our glazing was responsible for 5000 BTU, he probably over estimated internal gains at 3,000 BTU. I don't know. This is why I hired a professional to run the calculation.

We probably could have run the 12k unit and just not gotten as cool.

To clarify, the exterior walls of the unit are R30, the walls interior to the larger barn are R15, though the barn shell also has an R15 CCF, including the roof deck. But the windows are the cheap ones from Lowes.