Drying Potential in wall using Wood Fiber Insulation (Timber Batt)

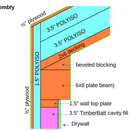

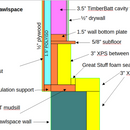

I’m building a small house (965 sq.ft.) in Downeast Maine (zone 6A). It will be post and beam construction with a thin layer of continuous exterior foam insulation (1.5″ polyiso) and 2×4 wall framing with wood fiber batt insulation in the wall cavity (3.5″ Timber Batt from TimberHP in Maine). The wall construction can be seen in the attached pictures (some simplifications in the images at the eave, but these are generally correct).

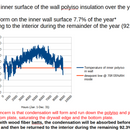

The wall construction is the standard offering from the provider of the house shell package that I am intending to use. I have some concerns that there is a potential for moisture buildup on the inner surface of the polyiso insulation at low outdoor temperatures. Using the assumption that the polyiso insulation has an average R/inch of 5 (NRCA suggestion for polyiso), and that Timber Batts have an R/inch value of 4, I can calculate the temperature of the polyiso for a range of exterior temperatures.

I have obtained the weather data for Bar Harbor, ME which should have a pretty similar climate. From this I have calculated the polyiso inner surface temperature for a year (see Figure 3). It looks like the polyiso surface may be below the interior dew point about 7.7% of the year (assuming 68F and 35%RH inside conditions).

Question? Does this raise any major concerns? My concern is that condensation on the polyiso will run down to the wall bottom plate and puddle there, saturating the bottom edge of the drywall and the bottom plate. I’m thinking that the Timber Batts may absorb any surface condensation on the polyiso and return it to the interior when the polyiso temperature rises above the dewpoint, which would be 92.3% of the year. Comments?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Have you read this article?

https://www.greenbuildingadvisor.com/article/how-to-design-a-wall

Your indoor humidity must be under 50% when it is cold outside or almost any wall and window setup will have problems.

The way I see it the proposed wood fiber insulation is more or less cellulose insulation It just skipped a life cycle as paper. Damps sprayed cellulose may give you a better fill at a lower cost.

Walta

Thanks Walta,

I agree about indoor RH < 50%. My design condition is indoor RH = 35%. I am also in agreement that the wood fiber insulation "should" be similar to cellulose. I was hoping that someone that has some experience with it can offer an opinion on its ability to store and release wall cavity moisture in a manner similar to dense-packed, or damp sprayed, cellulose.

Also, I have never seen a firm suggestion as to how much time spent below the dew point is OK if the wall is vapor permeable (Timber Batts claim 46 perm-inch, I have been unable to find a similar spec for cellulose). is 7-8% of the year fine? Is it a grave concern? Or something in between? I didn't mention it, but my design goal for air sealing is 1 ACH50, so pretty well sealed, with the air barrier on the outer surface of the sheathing, with the foam boards offset from the plywood and the foam boards taped.

cliffhaven_rob,

Your wall appears to meet the minimum R-value of foam in this article for 2"x4"constuction, and those values were not dependent on the cavity insulation being hygroscopic.

https://www.greenbuildingadvisor.com/article/calculating-the-minimum-thickness-of-rigid-foam-sheathing

You end up with a total of around R-21, which is fine, but not what we might call a high performance wall in climate zone 6A.

Thank you Malcolm,

Agreed that it is not a particularly high performance wall.

Slightly off-topic but I am curious if anyone knows how the values in Table N1102.5.1 came to be. It's clearly not to completely preclude the possibility of condensation from interior moisture, since in zone 6A the 2x4 wall with R7.5 exterior will have the condensing surface below the dew point for some period during a year. Is there a rule of thumb for the percentage of a year that has condensation that is acceptable?

The magic number to use is the average outdoor temperature over your 3 coldest months. This number comes from many test huts, it simply good enough.

https://buildingscience.com/documents/building-science-insights-newsletters/bsi-026-they-all-laughed

The wall still has a warm side vapor retarder, that painted drywall is a class III retarder, which will limit the amount of moisture that gets into the wall. You will still get some adsorption when the temperature drops bellow dewpoint, but these events are not long enough to cause any moisture issues. The assembly quickly dries once the temperature warms a bit.

Thank you Akos!

That makes total sense. For my climate data, the three coldest months average out to 27 F. At that temperature my wall construction yields a condensing surface temperature of 44 F. Good to go!