Hello everyone, I’m a builder who’s working on some framing details on my second double stud wall project. I want to tune this envelope even better than last time.

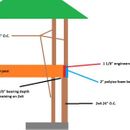

Below I’ve attached a picture of a diagram explaining what I’m talking about but I’ve got two questions for the experts here on the board.

1- it’s my understanding that code will not allow 2 stories and a roof on 2×4 advanced framing (24″ oc). I think single story is okay. If I was to change the first floor exterior load bearing walls to 2×6 advanced framing I would be code compliant then? And more importantly structurally sound? Has this been done before or does anybody have any opinions either way?

Also I was planning on only doing this on the first story eve walls as gable walls obviously don’t see the same load. (I joists bear on eve walls)

2- this 2×6 first floor eve wall plan then gives me a good solution for the rim joist insulation on this envelope. I’m curious if anybody has any advice on this design and what your thoughts are on the i-joist bearing depth. This design was inspired by a project I saw that Ben Bogie built

Southern NH

8′ ceilings both floors

James

Replies

James, scroll down to table R603.5(5) to see the stud requirements: https://codes.iccsafe.org/content/IRC2018/chapter-6-wall-construction#IRC2018_Pt03_Ch06_SecR602.3. The way I read it, your proposed design should be ok.

Gable walls are usually non-bearing so in that table you can see that 2x4 24" o.c. (laterally supported by sheathing) should work for gable ends.

There is more to advanced framing than using 24" o.c. studs; this section talks about top plates: https://codes.iccsafe.org/content/IRC2018/chapter-6-wall-construction#IRC2018_Pt03_Ch06_SecR602.3.2.

For headers, review this section: https://codes.iccsafe.org/content/IRC2018/chapter-6-wall-construction#IRC2018_Pt03_Ch06_SecR602.7.

The code includes bearing requirements, but for I-joists you should meet or exceed manufacturer specs. Here are the specs for TJI: https://www.weyerhaeuser.com/woodproducts/document-library/document_library_detail/tj-4000/.

Also be aware that many code officials are not familiar with non-standard construction techniques so you might need to have these code references handy, to explain what you're doing.

Michael, this response is so well written and helpful. You are one of the reasons this community is so great. Thank you for the info I really appreciate it

James

James, thank you for the kind words, and good luck with your project!

Has anyone ever thought to incorporate some of the lesser known codes that pertain to green/efficient building into a sort of primer borchure for code enforcement officials? That might help with the "but we've always done it THIS way" issues that come up on these forums periodically.

Hey, Taunton editors: maybe this is something you could do? A little brochure or booklet with some good details and references to specific code sections pertaining to high efficiency building details would be useful.

Bill

This would certainly be helpful here in rural NH. Although the tide is definitely turning, 10 years ago I would get a lot of grief but now even backwoods inspectors are interested to learn this stuff

James,

I think your problem is the bearing for the second floor exterior wall studs. In your section the 2"x4's only bear on 1 1/2" of the rim joist.

I agree that area at first look is shocking but Ben Bogie address it here (link below) and reassures its structurally sound. I have pondered a few ways to beef it up "just because"

skip to 46:40

https://www.youtube.com/watch?v=0PoNMzxELvg&t=2867s

James,

I don't know en0ugh about y0ur code to know whether that would fly. It wouldn't here in BC.

9.23.11.2 says:

1) A bottom wall plate shall be provided in all cases.

2) The bottom plate in exterior walls shall not project more than one-third the plate width over the support.

Malcolm, thank you for your info. I will research this detail further.

James

Coincidentally, Ben's detail is from a project I designed and he built; he resisted at first until we discussed it further. It may not work in a seismically active zone, and it does require a robust screw pattern; I'm partial to GRK RSS screws for this kind of detail.