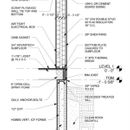

Double stud wall detail….review

I am attaching my proposed double stud wall detail I came up with. Let me know if anyone has any suggestions to improve it, or areas that are overkill/not needed.

The other option is running the ICF to the trusses. I like the benefits of full ICF, however from an energy standpoint (zone 6) I do not think they will hit the goals I am after. At an $8k add, I think it would be a step in the wrong direction.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

A couple of initial comments. If you align the studs with the roof trusses at 24"o.c., you can eliminate the double top plate to save on material and potential thermal transfer. It may require some additional tie between inner and outer stud but that can be done with OSB or plywood gussets. You have them shown at top and bottom but locating at the middle or at 1/3 points will give better structural performance. You could also look at putting the floor joists at 24"o.c. and aligning everything which can elminate the need for squash blocks or other joist reinforcing that may be required for the I joists. However, the rim joist should be verified for any concentrated loads from jack and king studs at large or heavily loaded opening. Don't forget to call for adequate roof and floor truss anchors. This is critical for both roof trusses and the basement wall to floor joist conntection. Nails alone do not work for the actual loads. Peel and stick can be problematic to install on a ICF wall and should have a protection board over it to prevent damage during backfill. Ideally use one that also has a drainage plain as rock backfill can become clogged over time and any water directly against the wall will reduce the effective insulating value.

Corian

Thanks for the feedback. A couple of my responses/reasonings...

I have framed 2x6 @ 24" oc before. While its easy to do, I still prefer the ease of the double top plates vs metal strapping. We tried that once, and the metal strapping was taking far longer then the double plates were. Costs were a wash when compared to cheap 2x4s. Also with 9' walls using standard precut 9' studs, it allows 54" gyp using double plates. This is just a pure preference really.

I have considered putting the 2x4s at 24" oc, and still might. I am wonder if the 2x4 on 24" centers would be pretty weak compared to 2x6? Maybe the inner 2x4 wall attached to the outer wall will greatly enhance this. If I need to add additional plywood gussets I can certainly do that.

However going with a 24" OC floor joist bumps me up to a 14" I joist instead of the 11-7/8". Not a huge deal, just added cost. It is actually cheaper having more 11 7/8" (at 19.2) then fewer 14" @ 24" centers.

Squash blocks would be added in addition to the rim board at king stud areas, however the loads are pretty minimal.

The peal and stick is what has been recommended to me by multiple ICF installers. The other option I have considered is the plastic dimpled products. Do you have any you recommend?

Simpson roof anchors would be used, just not shown in the details.

Jesse,

If I were you, I'd go to the truss manufacturer and ask them to build a raised-heel truss with a deeper heel -- as deep as your R-70 insulation. That way you'll get the full R-value over the perimeter wall, and reduce the chance of ice dams.

1. I would install a WRB over the ZIP Sheathing, just as 50+ year insurance.

2. I would install a rain screen behind the cement siding. Read best practices for Hardie siding installation guide.

3. CZ6 requires R49 on the ceiling. I would install heeled trusses with that height as minimum, more if you want a continuous R70 over the whole ceiling.

4. I’ve never used a double wall, but recently I’ve read about protecting those walls with exterior rigid insulation in case the sheathing gets wet or if there are holes in the envelope which allows air and moisture to move through the wall. Can that be the case?

I think I will look into bumping the heal up higher on the walls.

Does anyone have any further comments on the transition between the exterior air barrier to the interior air barrier at the ceiling?

Your drawing has the ZIP tape being used to seal more than just the seams in the ZIP sheathing. In my area ZIP tape is pricey. Also, I think I read on Huber's website not to use ZIP tape on anything except ZIP sheathing. See http://www.zipsystem.com/technical-information/faqs.aspx. If it were me, I would use Tyvek tape instead to seal interfaces between the sheathing and other construction materials.

Free advice... Worth just about that... I disagree with half the posts... Will leave it at that.

As for the horsepower of the 2x4 studs, this is from Robert Riversong, and when he posted it here, no one disagreed, fwiw. "A single SPF#2 9' 2x4 that's restrained laterally by sheathing or blocking can support 1820 lbs and a similar 2x6 can support 7061 lbs without buckling (almost 4 x as much)." So, be sure to check w/ an engineer on that for your loads. I am considering double 2x4's (built into T's) because they are cheaper and stronger than a single 2x6. PITA to put them together, and matching plates, but I don't have a day job, so....

Beautiful drawing and great comments - here's my thoughts.

I'd use a solid 2x10 or 2x12 upper top plate to air seal the tops of the walls rather than using 2x4 upper top plates and the 2x8 fire blocking between trusses you have detailed. (we looked at ripped 3/4" osb and the solid lumber was cheaper, stronger, and easier to air seal) I'd also run a strip of poly or house wrap from the drywall gasket, over the top plate and under the upper top plate to wrap over the exterior sheathing and tape to the Zip wall rather than trying to use zip tape to air seal to the upper top plate. (the strip goes on before the upper top plate) This way you don't have to tie the walls together with scrap plywood until the trusses are on.

I agree with others that the energy truss could be taller to maintain full r-value over the top of the wall but it looks like you have full depth to the baffle for at least the inner half of the wall and I get it (my wife is my architect) that raising the fascia too high off the tops of the windows is "glommy looking." (Just FYI - typically the wall sheathing stops at the top plate and the upper top plate is above the sheathing - the bottom chord of the energy truss typically runs over the upper top plate with the heel block on top running to a pitched cut under the top chord w/ no birds mouth cut in the top chord)

Typically airtight drywall gaskets are applied to the top plate and top of the foundation wall rather than to the ceiling drywall.

You should be fine w/ 2x4's 24" OC if you run a 2x3 horizontally at mid span to brace them in addition to the exterior sheathing. The insulation will pack better if you off-set the iner walls studs 1 1/2" form the outer walls studs - the right side of one should be in line with the left side of the other. this way you can pack your insulation fully in each cavity without having to struggle with getting a good pack in the space between the studs. Look out for the word "advantech" on the plans - it can prevent the builder from shopping for 3/4" osb subfloor which may be cheaper w/o the fancy name.

Rather than recessing your treated sill into the ICFs consider filling the ICFs to the top and bolting the treated sill above the ICFs with the sheathing extending down and nailing to the bolted sill. I'm in a hurricane zone but a common failure here is walls being pushed off the leeward side of the deck when the windward windows or garage doors fail. Assuming you are running the OSB sheathing perpendicular to the studs starting at the top plate you would have a 2' rip at the bottom with the sheathing gapped and taped at 12" above the floor. This gets the studs joined very well to the mudsill and rim joist. With an R-36 to 40 wall above you would want 8" - 12" of open cell foam on your rim joist.

Even if you never have heavy wind conditions, running the sheathing down to the mud sill allows you to run a strip of poly, house wrap, galvanized (not aluminum) flashing or EPDM from the interior of your foundation to the exterior of your sheathing where you can seal it with house wrap tape to your house wrap or zip.

Caulking the exterior 2x4 wall to the subfloor is a royal pain when the studs are in place and I really don't trust gluing the plate to the subfloor as it is raised. Minor point but I've gone to using a solid 2x10 bottom plate and ordering my studs an inch and a half shorter (easy for me to do - i'm a panelizer - may be harder if you are framing walls on-site)

Sorry for the long winded post - I'm supposed to be doing book keeping this evening.

thanks for the lengthy response. I will continue to refine my detail library. However for this project I think I will run the ICF all the way up. My overall wall r drops, however I am also reducing load in the basement since it was a full walkout to now full below grade. I think the other benefits of ICF out weigh the 1k btu jump in hvac requirements. The price is about a wash since one of my reps is giving me the forms at a reduced cost and also bring there for onsite training, pre pour inspection and present on pour day. Normally the double stud would be cheaper, but in this instance not so.

Windows are still up in there air as well. I am considering Pella's new 350 vinyl triple pane. Again, my rep can get me good pricing, much lower then Inline pricing with also the luxury of being local. I have checked them out in person, they are a very impressive window, especially for vinyl.