Do I really need any acoustical sealant?

So at this point my sill plate will have Henry CM-100 which is still sort of flexible, and a BG65 Sill Gasket. Over this will be wrapped Henry Blueskin taped to Henry CM-100 on the exterior and Intello Plus taped to the sill on the interior. It seems like applying a bead of acoustic sealant around the perimeter is beyond boots and suspenders… it’s boots, suspenders and a waistband But maybe I’m missing something? Should I still install some sealant in this assembly to keep a draft out?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Ethan,

Omitting the sealant would be denying yourself one of the great pleasures of building.

You will first notice it on your fingers or perhaps forearms. By then it will have transferred itself to the expensive Douglas hammer you treated yourself to. It won't show on the dark floor-mats of your truck, but can easily migrate from there when you get home, appearing as smears on the front hall carpet. Are you really going to forego all that because you think a membrane will do?

Ethan,

Henry CM-100 is a liquid-applied waterproofing compound. It is not sill seal.

Henry Blueskin is a water-resistive barrier (WRB). It is not sill seal.

Intello Plus is a smart vapor retarder. It is not sill seal.

If you stack up several materials that are not sill seal, do you get sill seal? I doubt it.

If you don't want to use acoustical sealant, at least buy some sill seal at the lumberyard. You can always caulk the crack between the mudsill and the foundation at a later time if the lumberyard sill seal isn't perfect.

Martin, you didn't mention the sill gasket. Is a sill gasket a sill seal?

Ethan,

My mistake! Sorry. I must have been reading too quickly. I missed the fact that you have a sill gasket.

You're all set.

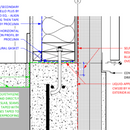

Martin, Thanks for taking another look. While I have this detail posted, I have another question... I am trying to figure out the transition between the rainscreen wall above and the insulated foundation below. Both cover a continuous plane of 8" of Rockwool. As you can see, we have draw in a floating piece of flashing, which in its current configuration isn't doing much. I would like to avoid I have an inkling that this flashing should extend all the way behind the insulation, but this violates the whole point of the detail which is to avoid interrupting the insulation, particularly at the sill plate! Perhaps we can just eliminate this flashing?

Ethan,

I need more labels.

What is the above-grade cladding or siding? Are there any furring strips?

What material is used to protect the exterior mineral wool below the Z-flashing?

Martin, I've reattached the detail with text on. Above grade cladding is currogated metal in most places, wood shiplap in others. Cladding is set off from Rockwool by furring, perhaps 2x but could be replaced with 1x. Below the Z-flashing is Finex (http://gofinex.com/en/fiber_cement_panels_finex.php). My question is regarding this Z-flashing... is it needed? Can it be on top of Rockwool? I'd rather not have it penetrate through. I've tried to look at the photos on articles here such as these:

https://www.greenbuildingadvisor.com/sites/default/files/Mark%20Yanowitz%20-%20installing%20mineral%20wool.jpg

https://www.greenbuildingadvisor.com/sites/default/files/Roxul%20Comfortboard%20IS%20with%20strapping.jpg.jpg

...but the location of flashing at the base of the Rockwool is ambiguous to my eye.

Ethan,

Yes, you need the Z-flashing. It doesn't have to extend behind the mineral wool, but it is definitely necessary to protect the top edge of the fiber-cement panel from rain.

Martin, thanks for clarifying something that I had also wondered about. Does it make sense to also lap a z-shaped strip of housewrap along the bottom of the wall sheathing and extending over the top of the foundation rockwool? (Like a flexible z-flashing). I was wondering if it would be useful to kick any residual water away from the joint at the foundation, but not have the kind of thermal bridge that Ethan is concerned about?

Though, with 8 inches of rockwool, it is unlikely that there would be water trickling down the housewrap in Ethan's case.

Ethan,

If you are going with corrugated metal siding, you will need a base-flashing to keep things out at the bottom.

Why not kill three birds with one stone and use a deep drip flashing which will cover the base of your furring strips, the bottom of the cladding and protect the top of the fibre-cement board below. Otherwise you potentially end up trying to fasten three types of flashing through the mineral wool in close proximity.

My own preference would be to get a really deep flashing that would extend out from the sheathing, separating the mineral wool at the slab level. That way you avoid any problems tryinging to keep the mineral wool co-planar as it moves from the foundation to the framing above.

Malcolm. WE have gone to great lengths to create a continuous and unbroken thermal break by staggering the seams of the Rockwool. If I can avoid it, I'd rather avoid creating a knife edge cut through the entire assembly. I am however intrigued by John Prospect's idea above and had considered the idea myself.

Ethan, I understand the intend, It's how practical it is to build that I'm cautioning about. The chances of your concrete foundation and sheathing above being exactly co-planar on the whole house are pretty slim. I am also not sure how easy it will be to fasten flashing through 4" of mineral wool.

i commented on that detail in another thread. It looks like a shop-drawing for something that will be manufactured. Details that will be successful on site need some slack in them. They shouldn't, for instance, rely on the baseboard trim to exactly cover the slab perimeter. It's asking too much and setting yourself up for trouble.

Malcolm. I know you've had problems with this detail. It has gotten even worse because in the excitement of pouring our specially formulated light weight, high recycled content insulative concrete walls, we omitted the originally specified perimeter foam...

But the good news is that our 8" conc. wall should be R-4, our 10" conc. wall should be R-5. I'm still trying to squeeze in 1/2 of foam at the slab perimeter. I just have to figure out if the Tremco Exo Air meets the Living Building Challenge requirements (it seems to be Red List Free). We will create the slab perimeter with a shimmed 1/2" board, remove it, and fill the gap with Foam (hopefully).

I appreciate your concern about exterior coplaner plywood/concrete... all I can say is that we will do our best and I think this is in all cases a material transition point anyway (see transition from Finex coverboard to rainscreen above) so any bit of non-coplaner can be taken up by the rainscreen?

Ethan,

I just want your house to turn out well without too many surprises during the build. Any criticism comes from that. If you can make all those fine points line up then you will end up with a really well performing wall. Good luck.