Did my engineer just break my heart? (vented attic assembly)

Ok, I’m just going to go ahead and vent. Actually, I can’t, and that’s what’s making me heated, literally.

I’ve loved my engineer, loved! Why, well, first and foremost, he’s an engineer, what the hell is there not to love.

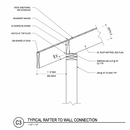

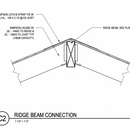

I’m a licensed builder in Southern California, working on a small 1,000 sqr foot modern Craftsmen style new construction project. All the structural details look fantastic on our plans, but in reviewing, the typical rafter to wall connection detail (attached) had me pause. I sent him an email immediately with attachments for venting at the eave (specifically on top of the blocking between the rafters at the roof sheathing), along with an example of a detail at the ridge providing for a cor-a-vent style static exhaust system. Here I thought – easy enough, we’re going to simply add in these details and be on our way to vented high performance.

Well, what do I know, I’m just a builder, not an engineer.

He shot both down. Saying that a) the blocking at the eaves is a critical part of the assembly b) the 2 x 1 1/2″ gaps in the plywood at the ridge would compromise the diaphragm and structural integrity (see detail attached – we called for a Simpson tie on each rafter.

I protested and said “why not cut the 1 1/2″ gaps at the ridge, then add the straps” — seemed like a solid idea. But to no avail.

Seems like I have to bore holes in the blocking and add a bug screen; then maybe use a solar fan somewhere in the middle of the roof near the ridge.

Anyone have a similar issue ? Any solutions out there?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

There is no easy answer that will not mean new drawings, that will most likely mean extra cost and delays if you have permit in hand.

At this point best work with what you have.

The simplest is to bore holes in the blocking for intake vents. You are probably looking at around 40 to 50 1 3/4 holes on each side for a 1000 sqft place, pretty quick job with a speedbore bit.

For the ridge, frame up a mini attic just bellow the ridge beam and add in gable vents on each side instead of a ridge vent. The nice benefit of the mini attic is that it will put insulation underneath your ridge beam which as shown is a pretty big thermal bridge (or at least up here in the great white north, maybe not an issue in your climate).

For the future, I would use I-joists and follow detail R3 W or R5 on Page 7 for intake vents:

For the ridge, detail R14 on page 8 works the best as it drops the ridge bellow the I-joist and you can have continuous insulation across the the whole roof.

https://www.weyerhaeuser.com/application/files/2115/5448/2409/TJ-9510.pdf

Unlike dimensional lumber, the thin OSB web of I-joists has much lower thermal bridging, increasing your assembly R values by a fair bit.

Yeah, boring I will go. Got an amazing set of bits I like, so this won't be much of an issue. But was really hoping to do that ridge vent detail. Will go another route. Thanks for the input.

Akos,

I’m looking over the Weyerhaeuser details you cited and am wondering how the ventilation chute passes through the blocking show in R14 to connect the V-cut at the eave to the ridge vent. Wouldn’t the blocking block the vent path?

Thanks,

Aaron

Aaron,

Their detail is pretty fussy work.

Much simpler is to make something close to a traditional ridge board out of an oversized rim board. End nail to the I-joists rafters for bracing. Ridge vents usually assume a ridge board, so a standard ridge vent would work.

If you don't want any lumber there, you can also get metal strapping and cross brace for support. I would check if this would be acceptable first.

Alex,

Codes differ in what they expect for seismic resistance - even in areas of similar risk. Here in Coastal BC we don't typically see the requirement for continuous attachment of the shear diaphragms at the ridge, but it seems to be a pretty common call-out in the rest of the PNW and California.

Another alternative, which maybe isn't very palatable, is to vertically strap the structural sheathing with 2"x material to create a ventilation channel, then add another layer of sheathing - or if the roofing is metal, another layer of horizontal strapping.

Yeah, not just trying to figure out the venting near the ridge. Thanks for the input!

I'm an architect in LA, those are the standard details far as I've seen with various engineers. I typically vent the attics with gable end vents, dormer vents, or O'Hagin low profile vents.

Seems like the consensus. The O'Hagin line seem interesting, thanks for sharing.

I can’t tell from the drawing will you have a flat ceiling a vented attic and lots of cheap fluffy insulation or a sloped ceiling and try to fit 20 inches of stuff in a 10 inch space?

On second thought it seems unlikely you are planning an attic because you have a ridge beam I would think a set of trusses would cost less than that beam and rafters.

Then at the end you talk about a solar attic fan. The study I saw said powered attic fans depressurized the attic and sucked enough conditioned air from the home make the home use more electricity when the fan was operating than when it was off.

If you must have the slopped ceiling consider a scissors truss design.

https://www.finehomebuilding.com/project-guides/insulation/insulating-scissors-trusses

Walta

Walta,

The sections clearly show a cathedral ceiling.

> The study I saw said powered attic fans depressurized the attic and sucked enough conditioned air from the home

You didn't post a link, but it's likely they were referring to high CFM attic exhaust fans that are used to remove heat. While the over-generalization is common, this has little to do with low CFM balanced or positive pressure fans used to remove moisture.

Would love to see the study as well. I'd imagine if there were more than adequate intake this would put less pressure on the attic floor assembly. We're going to air seal the attic floor pretty well, with rock wool on top which should add a little more airtightness when compared to fiberglass batts.

https://www.energyvanguard.com/blog/Don-t-Let-Your-Attic-Suck-Power-Attic-Ventilators-Are-a-Bad-Idea

https://www.energyvanguard.com/blog/the-1-reason-power-attic-ventilators-don-t-help/

So there will be an attic floor we can’t see in the drawings.

Why choose Rockwool for the attic when cellulose cost so much less for the same R value?

Why spend more money for the ridge beam and rafters if they are all hidden in the attic never to be seen again?

Walta

Interesting. So the engineer is worried about the rafters racking or uplift? Guessing this is a seismic concern?

Finalizing plans for 710sqft garage/adu and calling for scissor trusses to give the ADU some more volume. Plan is to vent with a Cor-A-Vent product, similar to the drawings here:

https://builderswarehouse.com/cor-a-vent-rs-400blk-raft-a-vent-1x15x225-black-48ct.html

Wonder if we'll have similar issues (inland PNW).

Sean,

The roofs get treated much like the walls as shear-diaphragms to resist racking in a seismic event. So like the walls they want them connected to the surrounding diaphragms.

If your project doesn't require engineering, the requirements for the connections will be in your building code.

Exactly. It requires engineering, even though it's a small structure. And due to seismic conners, my engineer won't let me touch the shear-diaphragms.

> Southern California

Have you done the 3 coldest month calculation to know if an unvented design would work with 0" of foam (with the IRC, local code may be different)?

We're venting the attic in this case, mainly due to costs per the client. Personally I love designs that decouple the roof/vent the roof, but keep the attic conditioned.

> We're venting the attic

> vent the attics with gable end vents

At 150:1, this is IRC compliant. And with a full attic design, I'm not aware of any evidence that, in your dry mild climate, there would be any advantage to soffit to ridge airflow.