Design for shower with exterior walls using polyiso

I live in Tucson, Arizona which is generally warm and very dry, with winters with overnight freezes and wet summers with periods of high humidity.

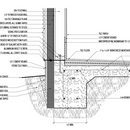

I am adding a new bathroom to a 1950s block house. Space is limited and three of the four walls are exterior walls; I’ve elected to use 2×4 stud walls with no cavity insulation and 2-1/2″ of foil-faced polyiso on the outside of the assembly. Everything looks great except I am not sure how to design the shower, which is a walk-in, tiled “wet room” with two exterior walls, one of which has the plumbing. Since the polyiso is vapor-impermeable, the wall assembly must dry to the interior.

Traditionally around here people just put up cement board and tile with nothing behind it (or perhaps building felt). When I took apart the original tub/shower surround in the main house it seemed to hold up fine, but the house is block and has no insulation and no vapor barriers.

I’m looking at just specifying cement board and tile, using a waterproofing membrane only in the floor and running it up the walls about 12″ behind the cement board. Given the general low humidity out here, and the fact that I’ll have a good exhaust fan on a timer, I think this will work. I thought I’d put it to the experts here… am I missing anything? Should I spec building felt behind the cement board to act as a drainage plane, or would that just trap moisture in the wall cavity?

Thanks for the advice! (See attached drawing for details.)

Ryan

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

just from the tile standpoint & based on all the failures I used to see out there, I would suggest running Schluter Kerdi or a similar product up the entire wall. Along those same lines, you might want to check out the shower kits that they offer so you don't have a mortar bed just sitting there holding water

Thanks Sean. I am worried that the low vapor permeability of the polyiso would prevent the wall from drying out properly if I used a continuous waterproofing membrane up the entire wall. Can anyone speak to that?

Ryan,

In your climate, it's hard to imagine that your concrete block wall will ever get wet from the exterior -- especially if it is covered on the exterior with polyiso.

What's your siding? If you are worried about exterior water penetration due to flashing failures, you can always install a rainscreen drainage gap between the polyiso and the siding.

Martin,

I'm sorry, I'm afraid perhaps I'm just not very clear. The original house is block, but I'm building an addition that uses 2x4 frame, polyiso on the exterior, and a ventilated rain screen. My question is about a shower in the addition, not the original house. I am not concerned about bulk water intrusion from the exterior, but moisture from the shower getting into and out of the wall. See the drawing attached to the original post.

Let me restate the question: I have a vapor impermeable layer on the exterior and a shower on the interior. If I use a waterproof membrane (like kerdi) behind the tile in the shower, am I not creating a building sustainability faux-pas by using an impermeable layer on both sides of the framing? Can I get away with omitting the membrane behind the wall tile in the shower so moisture can dry to the interior?

Thanks again!

Ryan,

OK, now I get it. You're right that it's not a great idea to sandwich 2x4s and plywood between two impermeable layers.

How about switching to steel studs -- at least at the shower area -- and omitting the plywood? (You could leave the PT bottom plate.) As long as the wall was adequately braced elsewhere, that would eliminate the worry about the lumber in the wall.

Martin,

An architect friend of mine also suggested steel studs, and we chatted about it but ultimately decided to stick with wood. I'm not entirely clear on why though, I've slept since then. I think it seemed better to solve the moisture problem by means of providing for adequate drying rather than increasing the complexity of the project by adding more material types. It might also be that I'm a carpenter and steel is not something I'm accustomed to working with. It may be I just need to get over my love for wood and embrace steel, at least for this.

With steel studs, would you omit the waterproofing membrane behind the tile so the wall can still dry out?

If it is well enough to leave a PT bottom plate, could I use PT studs instead of steel? (I get that the plywood would have to go, but as you said there are other ways to provide bracing.)

Another option I considered was to ventilate the stud wall. I would run a continuous vent along the top of the shower wall for exhaust. Since a continuous intake vent along the bottom of the wall is plain silly, I considered boring 3/4" holes at 24" centers through the wood studs and providing an intake vent on the opposite side of an interior shower wall. Theoretically, this would allow air to circulate through the entire wall assembly without poking any holes in the air barrier or inviting bulk water into the wall from the shower.

Ryan,

I wouldn't recommend the idea of venting your stud space with interior air. Yes, you could use PT studs if you are worried.

But you are probably overthinking this. As long as your wall cavity is dry on the day that the Kerdi system is installed, you are unlikely to have any problems.

How is this detail (shower on an exterior wall) handled in the REMOTE or PERSIST model?