Deck ledger flashing on wall with continuous insulation

Morning folks,

I’m trying to wrap my head around how to best detail our deck ledger. We have 1″ silverboard HD XS going on the walls and the foundation is ICF. I like the idea of standoffs, but because the walls will get 3/4″ furring and 1/2″ vinyl on the same face as the ledger the gap is not really that exposed and i’d need a pretty big drip edge under the ledger in order to make sure water was not getting behind the siding.

The silverboard is our air and water barrier, so I was thinking about packing out the rim by 1″ to match the foam thickness, and then flashing with butyl tape from foam to icf over that pack out to keep the air and water layer continuous. Then L flashing (and tape) above the ledger, and drip cap (and tape) below. I know some places allow for the ledger to go over the foam, but I’m not sure that’s allowed in Ontario. Pretty sure I read somewhere that it’s max 1/2″ for that detail.

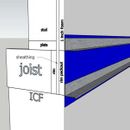

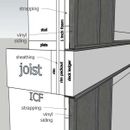

I have attached some pics…thoughts?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Ya I definitely wouldn’t attach ledger over foam, even 1/2”. On exterior foam you can just use a larger ledger board to achieve your buildout and still attach at sheathing but since your air water barrier is your foam I think the packout makes sense. They do make spacer washers for ledgers that give you a drainage plane that I would recommend. Also I would also have a flashing tape under your metal flashing at the ledger and you metal flashing should be a z type that continues down vertically on the ledger for a bit.

Does your sheathing not go over your rim joist? That is weird and much weaker.

Lastly

You should size it the height of your deck joist plus decking. This eliminates the weird dead space that traps debris on top of ledger.

Oh also I would not trust butyl tape in a reverse lap situation. I would trust some of the nicer euro tapes so you could use one of those on the leading edge, as butyl tape is probably more robust behind the ledger then a high performance tape.

The sheathing does go over the rim, drawing corrected.

I bought the deck to wall spacers, but I'm not sure how to approach it. The strapping and vinyl stick out approx 1.5" past the face of the foam, which means the path for water is set back under the J trim...is that an issue? I'm guessing not if a Z trim is on the ledger as the water can't go between the back of the ledger and the face of the wall anyway. The ledger and whole frame will have joist tape.

Not sure I follow your height comment...size what?

Good point on the taping, in reality I should probably start the tape a few inches up the sheathing, over the top of the packout and down, then put a strip from the face of the foam down to the start of the packout to air seal.

I don’t really understand the first question but that z flashing will take water from drainage plane to front of ledger. Also mike guertin has a good fhb write up on deck ledger flashing.

For height see attachment.

Also keep in mind you need lateral resistance members for decks, generally joist to joist, that you should plan for ahead of time. Something like Simpson dtz. But as your air and water sealing will happen behind ledger make sure if threaded rod is used you install ahead of time and seal.

I simply meant that there would be an overhang of materials over the gap behind the ledger if I used the spacers. I'm trying to decide if it's worth doing since the packout would be taped, and the ledger would have Z flashing above and below. Water can't get to the space between the ledger and the wall in that scenario.

Mike's article has no spacing, and uses metal flashing directly on the ledger if we are talking about the same one.

Your drawing clears up your comment perfectly. So you're suggesting the Z flashing be above the deck boards?

I've never seen those DTZ connectors before? Where are you that those are required? Our drawings don't show anything like that.

If you are using irc in North America lateral bracing for decks has been required for a very long time. Again Mike guertin has a video on it.

It maybe be true that bulk water will not get in there but capillary action will pull it in. It’s just a little extra insurance against a common failure in ledgers.

OronoWoodworks,

See page #18 for the lateral attachment requirements:

https://cms7files.revize.com/watertownct/Departments/Building%20Inspectors/AWC-DCA62015-DeckGuide-1804.pdf

Freyr-design,

"You should size it the height of your deck joist plus decking. This eliminates the weird dead space that traps debris on top of ledger."

An often missed detail. I go the other way and put the ledger 1" lower then the deck joists, leaving you a gap under the deck boards for drainage. Both work much better than a flush ledger.

I like it...so how does that get flashed? Z flashing above deck boards just below siding?

OronoWoodworks,

The flashing runs over the top of the ledger as usual, but the gap allows any debris and water to drain. Dropping the ledger lets you run the first deck board part way over the flashing to hide it.

I'm assuming the z flashing just gets notched at each joist

OronoWoodworks,

No it runs down the face of the ledger an inch and that get sandwiched between the ledger and the ends of the deck joists.

Ok gents, thanks for the info, I think I will use the spacers.

So to recap

1 - Pack out rim to face of foam

2 - Tape from sheathing over pack out down to ICF.

3 - Tape over z flash under ledger

4 - Tape from face of foam to pack out tape for air seal

5 - Install ledger with 1/2" spacers positioned lower than joists

6 - z flash and tape from face of foam over ledger

I'm late to the discussion but that's what I would do. If you want to save a few BTUs, the pack-out doesn't need to be continuous, but it will be easier to install if it is.

The other option I've used is a Maine Deck Bracket: https://deckbracket.com/. But they have their quirks, including needing more of them than most people think they need, so I save them for special occasions or when contractors want to use them.

We are using simpson SDWS screws, and they need to be every 8" in our case so it would be pretty pointless to make it non-continuous. I'll insulate the cavity really well.

I have Zip R-12 on my exterior, 2-1/2" total thickness. I used the Maine deck bracket standoffs, worked really well. Brackets are bolted directly to rim joist and sealed well with a combination of tape and liquid flash. The deck is on an eave end of the house in VT where we get allot of snow. I have not had any problems in 4 years