Critique of cathedral ceiling and wall design – Swedish Style

Planning on building a 1-1/2 story, well insulated home using 14” I-joists as the rafters. Then running 2 x 4” horizontally. The I joist cavity will be air sealed. The 2 x 4” cavity will not. I will have an ERV. This idea is a mix of concepts seen on greenbuildingadvisor.com, buildingscience.com and the USA new wall info provided by Gregory La Vardera’s site on Swedish framing/insulation – http://www.lamidesign.com

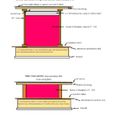

After seeing all the horror stories regarding trapped moisture, I’m seeking advice to help me in building my own home. I’ve attached an image of the ceiling and wall designs I’d like to use.

I like the idea of the bulk of the insulation cavity being well sealed and free of penetrations that would allow moisture to enter from inside the home. The horizontal 2 x 4 cavity would not be air sealed or have an inside moisture barrier of any kind. Any moisture that enters there would dry to the inside.

Questions on roof construction and insulation:

– Can I use the less expensive 2.2” EPS (R10) for making my air channel vent under my roof sheathing? Or do I need to use the more dense, vapor barrier XPS 150?

– The 2 x 4 horizontal cavity will be filled with batt insulation. All electrical and water supply pex will go in this cavity. The only penetrations of the air sealed I-joist cavity would be for plumbing stack(s) and a chimney for a wood stove (yes, I’m providing fresh air for it).

-With this vented cathedral ceiling design, are there any concerns with dew point/condensation on the inside of the I joist cavity?

Wall

The walls will be standard 2 x 6 with blown in insulation and the same horizontal 2 x 4 cavity filled with electrical, pex water supply and batt insulation. Membrain would be used as the air/moisture barrier between the 2 x 6 wall joists and the 2 x 4 horizontal cavity.

– Any concerns?

Thanks much for any advice you can share.

Jeff

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Using 2.5" of unfaced Type-II (1.5lbs nominal density) EPS is superior to XPS or polyiso in that application, since it offers something like 1.2 perms of drying capacity into the channel. With 2" XPS you would have half that, and with foil faced polyiso you would have dramatically less. The interior side MemBrain would normally run less than 1 perm in winter, so with 1+ perm EPS the cavity would be drying to the exterior even in winter- you 'd have virtually no moisture accumulation.

With XPS or foil faced polyiso it would accumulate some moisture, unless the ratio of the foam-R to fiber-R was high enough to keep the average winter temp at the interior side of the foam above 40F. As drawn you have very low permenace R10 foam, R32 cavity fill, the foam effectively 24% of the total R is on the exterior side of the condensing surface, which is going to be good enough for US climate zone 4, but a bit marginal in climate zone 5, which means you would be relying heavily on the performance of the MemBrain. If adding R13 to the service cavity which would make the foam-R only about 18% of the total, with an even more heavily on the MemBrain.

Bottom line, going with 1+ perm EPS instead of lower permeance foam makes the assembly more resilient and keeps it drier by staying ahead of the moisture diffusion that gets by the MemBrain, and makes the R-ratios far less critical.

Jeff,

I'm not a fan of locating any plumbing pipes in insulated sections of exterior walls. You don't say where you are located. I imagine that in most areas of the U.S., the likelihood of your pipes freezing would be relatively low. But here in Vermont, I've seen pipes freeze when they are installed in insulated stud bays.

If you agree with my concern, you can relocate the pipes. Or you can just make leave the service cavity uninsulated.

Except for the issue with the pipes, your assemblies look OK and represent fairly common approaches. Your suggested cathedral ceiling is a typical vented assembly. The wall is also very common -- often called a "Mooney wall."

For more information on service cavities, see Service Cavities for Wiring and Plumbing.