ConditionedAttic-PortlandOregon(zone4)

Trying to take this 1970’s attic and make it a conditioned space (not a living space) so that I can maintain the HVAC that are the heating and cooling of this 1600ftsq ranch.

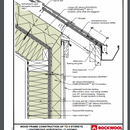

My 1st stab was to take this wall and roof profile from Rockwool (see below). Not a contractor but the owner, but felt I could handle Rockwool 2’x4′ 2.5″ panels and do a reasonable job.

Ran this past an engineer and the weight exceeds the truss tolerances so that only 1 layer of 2.5″ Rockwool is within limits. Not sufficient insulation. Trusses are 2×4 on 24″.

What recommendations for a roof assembly to support a conditioned space attic and any contractors/roofers in the Portland area is anyone familiar with that could do an install of ideas/recommendations.

thanks

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Tommy,

Have you considered a similar assembly but substituting foam for the rockwool? Weight then wouldn't be an issue, and it could be left un-vented.

Malcolm thanks for responding!

Every time I look at foam for the roof exterior, I'm concerned with the ozone impact of slow blower agent release and global warming potential. Trying to be a good steward.

What foam assembly has minimal HFC and global warming over the life of the roof assembly and if you could point me to a URL describing the technique that an expert member of greenbuilingadvisor.com would recommend. I'd like to get well above R40, eliminate thermal bridging, etc.

Thanks!

Tommy,

Our company did a spray foam-free retrofit on a single story ranch in Portland, OR where we created a 'headhouse' to store the mechanical equipment. One could swap out the foam baffles with a wood fiber insulation product if one was looking to go completely foam free. I've attached the details here along with a pic of the finished space. We were able to fur down the 2x4's with a site made plywood truss and then create a vented and insulated assembly. We then added Siga Majrex as a smart vapor control and air barrier to the underside of this. The assembly was then filled with cellulose insulation. More info is available on IG, link here: https://www.instagram.com/p/CUlEmbhhD_I/

That, I think, is a bit beyond my skillset.

You have a video, "Building a Vaulted High-Performance and Foam-Free Roof Assembly" which I thought was wonderful. Wish I had that option.

Tommy,

You may find this useful: https://www.greenbuildingadvisor.com/article/choosing-rigid-foam

EPS/GPS seems the choice at this point.

With a vapor permeable membrane over the current sheathing, can I confidently assume the sheathing will dry to the outside regardless of the EPS/GPS thickness?

Portland-Zone4, is there any negatives to using furring strip to mount metal roofing with the created air-gap.

thanks