Tank-Style Water Heater for Hot Water and Radiant Floor

Our Indiana home has TWO 40 gallon, 40,000 BTU water heaters. One is for the Domestic Hot Water, the second for a small radiant floor. Both are 15+ years old, and need to be replaced, ideally with a single system.

I’ve read many GBA threads about combination Heat and Hot Water systems, e.g. Polaris, Phoenix, various Combi floor and wall-hung systems, and even mod-con boilers connected to an indirect tank for the DHW.

My question is, for a small radiant floor such as ours (10-15K BTU load) can TWO ordinary tank-type water heaters be replaced by a ONE ordinary tank-type water heater (by incorporating a heat exchanger for the radiant loop, increasing the tank temperature, and mixing the DHW back down to ~120F?? Many have described doing so with using specialized stainless steel condensing modulating water heaters e.g. Polaris, and Phoenix, but for a small heating load this, is there any reason not to just use an ordinary commodity water heater readily available? The aforementioned Phoenix/Polaris units seem to be less common in local supply houses, and I notice plumbers shy away from installing them, citing lack of confidence of being able to service and support them.

A tank-type setup seems attractive compared to all of the various expensive, complex alternative(s), e.g. mod-con running at the lowest-firing rate for the floor, with an indirect tank for DHW, or worse, a COMBI unit small enough to not be oversized for the radiant floor, yet therefore undersized for the DHW.

Having a thermal store/buffer in the form of a tank of water seems like an ideal way of dealing with DHW demand spikes and buffering the heating load versus adding capacity and modulating complexity. So I guess my question is, is the ordinary tank-type water heater up to the task, for minor space heating, or should I seek out a more specialized tank type unit like those mentioned? Now that AO Smith has acquired Polaris, and HTP is selling under the Westinghouse brand, does that change the sales and service end of things to where my plumbers fears of serviceability are unfounded?

p.s.

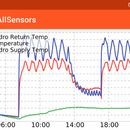

I base the heat load calculation on measurements from our existing Bradford white unit (a regular tank-type 40,000 BTU water heater). See the attached picture showing rising supply water temp while the burner’s firing, and dropping when it’s off. Assuming 80% efficiency on the Bradford White unit, the unit should be putting 32,000 BTU into the water storage tank when firing. It’s evident from the hours-long long call for heat, that the unit’s burner is actively firing roughly 40% of the time, so if my math is right, I think that works out to 12,800 BTU’s.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Some water heaters are actually rated to act like "mini boilers" for heating purposes like this. You'll need to check if the units you have are rated that way. If your units have the correct rating, then you CAN use them for heat by plumbing a recirculating loop through your radiator/radiant panel/etc. You do want to use a heat exchanger to keep potable water seperated from your heating loop.

Bill

Interesting. Any examples that you can think of from the big players like AOSmith/Bradford White etc? Your post is really encouraging. Thank you for sharing.

Any idea why so many discussions about combined systems seem to center around the stainless steel specialty units? Could it simply be that being stainless, they end up being economical long-term, thus more attractive to heating geeks and profiessionals?

In my existing setup, the radiant water temperature varies greatly (clearly seen in the graphic on the original post). It's one of my major gripes because obviously when the tank temperature is falling, the lower temperature Delta means LESS heat is transferred into the living space for period of time.

Is it common to incorporate some kind of secondary temperature control unit on the radiant/hx side to ensure stable temperature?

My application for this sort of thing is a little different than most: I like using water heaters as a cheap way to setup a hydronic heating system for greenhouses. Greenhouses are an incredibly harsh enviornment for heating systems due to the constant high humidity levels, and watering. Fin tube is about the most reliable heating equipment you can use, but it needs a source of hot water. Boilers are more expensive than water heaters, so water heaters are a cheap way to go.

I can't point to a specific example, but you'll find the ratings buried in the specs for the units. I'm not aware of any water heaters specifically marketed for this sort of thing, so you have to dig into the data sheets to see if they are rated for use for heating. I've never used anything fancy, but I've also used the water heaters as dedicated "boilers" too, so I haven't had any issues seperating potable water from the heating loops -- there are ONLY heating loops in my application.

Your big swings are probably an issue with a boiler cycling. Maybe you need a buffer tank, or an adjustment to the boiler?

Bill

Not the easiest to find without doing some digging. Generally combi rated gas tanks will have a larger burner, typical is around 75000BTU even on a small tank. I would check with your local suppliers to see what they stock and check data sheets from there.

There are some manufacturers that offer units with a built in coil which simplify the install. Look at Laars Combi or Bock EZ75-76PDVN-C.

Most tankless units are also rated for combi heat, they are more restrictive so you need to use a high head pump for the heat exchanger. Keep in mind that they have a minimum fire rate which needs to be bellow your your space heat load. This can be problematic with zoned systems which will can wear out the unit from excessive cycling.

In most combi applications you run the tank pretty hot to have extra buffer capacity for hot water use, so make sure you install an anti scald mixing valve on the domestic output.

You can also install mixing valve on the space heat loop if you want better temperature control there or you need a low temperature loop for floor heat.

An accurate estimation of the heat emittance (or absorption, if a slab) of the radiant zones (rather than simply the 99% design load) are necessary to figure out the minimum burner size in a combi application. Typical burners in a 40K tank type water heater deliver 32-33K to the water, and as the tank temp rises that number drops a bit- don't count on more than 75% efficiency if the return water is ~115-120F. A 10-15K design load using could easily have 20-25K of initial absorption on a new call for heat, and would be taking pretty much all of the burner capacity at the beginning of a call for heat from massive radiation such as slabs, with nothing left over for domestic hot water.

Tank water heater heat exchangers are designed to tolerate a large delta-T at the beginning of the of the burn when the bottom of the tank is <<100F, but if run chronically with an EWT of <120F water the center flue heat exchanger can be damaged by condensation, shortening the overall lifespan. If run above the condensation temperature zone (which varies by manufacturer & model) they can last a long time, but if it's running on the edge it may be toast in just a few seasons. This application calls for a condensing water heater, and a burner well north of 50K.

A (comparatively) inexpensive water heater that would fill the bill with possibly better local support is the AO. Smith Vertex GPHE-50, which is explicitly designed with potential low-temp space heating in mind. It has a NON-modulating 76K burner (not 75K, to get around residential water heater testing protocols which make it look less efficient in a water heating only application), and has purpose-designed side ports for space heating. See Figure 2 (a "open" hydro-air heating solution):

https://s3.amazonaws.com/s3.supplyhouse.com/manuals/1329168611501/71279_PROD_FILE.pdf

The Vertex GPHE-50 has a bit more burner output than your PAIR of 40 gallon 40K ~80% water heaters, and a bit more storage to boot. If your current setup works for you, this should work even better. With the radiant floor zones it's generally safer/better to use a plate type heat exchanger between the potable and heating side, which allows the heating side to run at a more appropriately modest pressure, and to use ferrous & other potable-incompatible valves, pumps, etc.. Only the heat exchanger and the tank-side pump would need to be potable compatible.

Before you combine the two systems make sure you understand the risks you would need to except should you combine them.

By mixing the heating water with the domestic water you have the possibility that some parts of the system could be stagnant for several months harmful bacteria could grow and get into your drinking water.

Yes with the correct pipe layout it may be possible to reduce the dead spots assuming no one later changes the flow.

Many locations prohibit combined system for safety reasons.

You may want to find out if you can legally combine your systems give your location.

How sure are you that the savings are worth the all be it small risk of death?

Walt

If the heating system wasn't commissioned as a potable water system it's considered non-potable, there's no way to make it potable. So the two systems have to be separate. They can be connected with a heat exchanger. You can either put a heat exchanger on the domestic hot water which heats fluid for space heating, or you can put a heat exchanger on the heating circuit to heat domestic hot water. Generally the second way is better because generally heating runs at a higher temperature than domestic hot water and it's simpler to have the source hotter.

What temperatures do the two heaters run at?

The replies so far have been helpful. I'm extremely grateful.

This morning I've been considering the fact that Polaris is expensive, but seems to have a long/good track record in this application (Assuming the thing gets installed correctly: venting, hardness, expansion tank, and definitely a HEAT EXCHANGER etc.)

AO Smith now owns the Polaris product, so maybe local plumbers would be more comfortable with installing it. With regard to short-cycling using a 50 gallon unit: The start-to-start time of the current 40 gallon tank is about one hour. Seems pretty good. For about about 30 minutes, the tank is cooling down, then for the next 30 minutes it fires, and catches back up. My 40 gal tank happens to have about 20F of swing temperature.

My initial thought was that the larger tank of a 50 Gallon Polaris would INCREASE the start-to-start time, but as I think about it, the time would actually DECREASE fairly significantly Not only would the Polaris's high fire rate cause the tank to recover in just a few minutes (say 6), but the Polaris setpoint dead-band is only 8 degrees (by default), so it would be more temperature stable, but would cycle more frequently. Maybe every 15 minutes.

Changing the Polaris controls could achieve the same 20F deadband (20F is the max the Polaris allows). However, that would probably then require a temperature mixing valve/system to regulate the supply side to the heat exchanger (from the tank) to enable the desired 120F radiant supply temperature. Maybe that's a good (typical) thing to do anyway, since the current temperature fluctuation is one of my gripes.

SO IN ESSENCE, with 20F of swing, the start-to-start cycle time might be around 40 minutes, however I think it ALSO means that the tank temperature would need to be set HIGH ENOUGH so the BOTTOM of the deadband would be equal to the minimum temperature required at the heat exchanger. I'm not sure what supply temperature that works out to be, but if if the minimum supply temperature were say, 140F, then 20F of swing would mean that the Polaris tank temperature could at times be as high as 160F! My gut tells me that would violate some design elements of an efficiency-optimized water heater, but the AO Smith tech said that's not a problematic temperature, in fact he says it's better for the unit to run hotter (esp with respect to reducing condensation). I'm not sure if that matches real-world observations..

How much temperature differential is desired across the HX? Is the floor supply side normally regulated by varying the supply side (from the tank/heater) or does the radiant loop just mix some return water to achieve a steady supply temperature? If my plumber will work with the Polaris, would a Polaris heater be an *optimal* solution?

Interesting: The Polaris is advertised as a modulating unit BUT nowhere in their specs do they specify the actual turn down ratio, nor minimum fire rate. When I asked AO Smith tech support about this, the guy said that the modulation function is a bit misleading, since it's not modulating in the traditional sense (of trying to match the load), but modulating in the sense of slightly adjusting the firing rate during start and stop to improve combustion efficiency. TL;DR: NON MODULATING. Does that match anyone's real world observation? Also, apparently the old plate igniters that Polaris used would fail every few years, but they have since been changed to a spark type igniter. Maybe that problem's gone.

What is the reasons why you wanted to combine these in the first place? I'm going through the same thought process for DHW and potentially a small amount of radiant. Were you trying to get more efficiency by combining, more space?