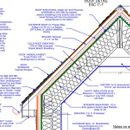

Cold roof detail Zone 5A

Hello,

I have designed the attached cold roof detail. Now that the project is about to start, I have been thinking on modifying the insulation setup. I want to use a R-21 closed cell in the cavity and add a R-30 fiber glass or rockwool. I don’t want to install the exterior Polyiso as it will create a non permeable sandwich for the sheathing. I understand that the exterior roof CI may produce an energy penalty on thermal bridging, but it appears not to be significant. Another option is to fill the cavity with closed cell foam but from what I understand after 2 to 3 inches of spray foam, there may be some installations issues?

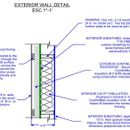

The walls will continue to have R-23 rockwool for the cavity with a Comfort Board 80 as CI. Although, with all the supply issues with mineral wood I may consider changing the Conforboard 80 for Polyiso at least on the non fire rated sides of the house. If I decided to use polyiso, does a “rain screen” between the Polyiso and the sheathing is required? I was under the impression that since we are using mineral wool in the cavity, there is a path to “dry” to the interior.

This is a single family addition/remodel where 90% of the walls and roof is new.

Thanks!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

I see several problems with your proposed design. I recommend reading this article: https://www.greenbuildingadvisor.com/article/how-to-build-an-insulated-cathedral-ceiling.

Thank you Michael for the link. I have read that article. Are you referring to issued with Skylights and side cross roof? I have eliminated the skylights as they are not needed. I forgot to mention, the roof has is monopoly framed so it made sense to add venting on the sheathing. The structural sheathing is ZIP system. Obviously, I could be missing something.

Maybe I'm not following. Your drawings show a likely condensation problem due to insulation ratios (permeable vs. impermeable), but your description of a flash-and-batt system will probably be ok. "Cold roof" is shorthand for a vented roof, but closed cell foam is almost always used with an unvented roof, sometimes called a hot roof.

Next week's BS+Beer show will be with Henri Fennell, a spray foam expert, talking about how to do things right so you might want to tune in or watch the replay. Generally, older formulations of closed cell foam could only be installed in 2-3" lifts but most installers are now using foam with reduced global warming impact which can be installed in thicker lifts, up to 7" for some brands.

Don't confuse "reduced global warming impact" with "no global warming impact;" closed cell foam is still among the worst products you can use in construction and should not be necessary on new construction, especially with a vented roof.

Tyvek Protec 120 is already impermeable (<0.05 perms). And so is Zip Ice and Water. Your logic of not wanting to install exterior insulation because it is impermeable therefore makes no sense. Even without the exterior insulation this assembly is already incapable of drying to the outside.

As far your comment about drying to the inside of the roof assembly, if you install closed cell foam your assembly will not be able to dry to the inside either. If it was just batts or a loose-fill product like cellulose or fiberglass then it would be able to dry to the inside. Having some closed cell followed by mineral batts does not improve the drying situation, the closed cell foam is your limiting factor and it is relatively impermeable especially at the thicknesses you are talking about.

Agree with Michael that you could easily engineer out the closed-cell foam and use a different product instead. I'll also through out that mineral wool is not the most environmentally friendly product either.

Thank you Matt, I'm sorry It was not clear but the Tyvek is on the second layer of OSB over the ventilation channels. So it will be ZIP System as structural sheathing, then 2x4 on flat for venting and finally a typical roof assembly (OSB+Tyvek+shingles). So if I have spray foam below the ZIP System (cavity) there won't be anything on the ZIP System because of the venting channels. I agree this description differs from my drawings. I've should have done a better job explaining and posting drawings. Basically is adding a second roof on top of the structural roof system.

Agreed on engineer out the closed-cell foam.

Why do you want a vented roof if you're doing spray foam?

Initially I did not have spray foam. It was rockwool under ZIP System and Polyiso plus venting channels on top of the ZIP System. I was proposing the attach detail.

So what I'm getting now is that if I use Closed Cell Foam, I don't need to have the venting channels on top of the ZIP System? would the shingles be nailed directly on the ZIP System without the Tyvek 120? because if we add the Tyvek Protect 120 and Ice and Water barrier, then we will have the ZIP System between 2 layers of impermeable materials (Foam below and Tyvek above for the shingles. Am I overthinking this?

I would rather have a vented roof with low-carbon insulation than an unvented roof with high-carbon insulation (aka foam, or mineral wool) but if you're set on using those materials, you don't need to vent the roof. That was covered in Martin Holladay's article that I linked to.

Zip sheathing doesn't require a separate underlayment but you can add one if you want. Roofing is impermeable so the perm rating of the underlayment does not matter. You do need to follow code requirements for ice and water shield, even with Zip sheathing.

Ideally the roof sheathing would be able to dry to one side, but it's not critically important--with your proposed assembly, no moisture should be able to reach it.

Okay, so vented roof but unvented attic. I think I follow now. I guess that will work. The two layers of roof decking seem a bit unnecessary but I can't think of another way to dry to the exterior and use shingles without it. If you were doing metal or other panelized roofing you could get by with just the furring strips and no second layer of decking.

@Michel Maines - Thank you for for your comments. I was looking into a GBA article on low-carbon insulation and Close-cell + mineral wood at top on the list for worst... But with 12" rafters I still may need to use some foam combined with fiber glass I believe. Now I'm not sure on the venting as you pointed out that ZIP doesn't need roof underlayment... How it looks like from a maintenance point of view? Would the ZIP be damaged when new shingles are needed? After all ZIP System is just OSB with WRB adhered.

I see some benefit on the second layer of OSB to vent it and let the Structural ZIP System alone but it also has some implications that somehow worries me. I think one of the problems I may have is that framers may not be able to assure the right construction along with potential issues with penetrations.