Code for Lower R-value in Ceiling if Closed-cell Foam is Used

Hello All,

Building in zone 5 (south west idaho) where the county uses the 2017 Idaho Residential Code; which is based on the 2012 International Res. Code.

https://codes.iccsafe.org/content/IDRC2017/chapter-11-re-energy-efficiency

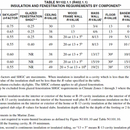

While collecting insulation quotes, one of the vendors suggested that if were to use spray foam (closed-cell specifically) at the underside of the roof deck that I’d only need R-21 rather than the R-30 that is indicated in the code’s insulation table (clip atch’d).

I can’t find any such ref. in the code. I have asked the vendor for reference but I haven’t heard back yet. Has anyone heard of this reduced rating (perhaps based on ACH dropping).

Thanks.

WD

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

That is spray foam industry BS. Spray foam R value is not magical, and is no better than any other insulating material’s R value. You don’t get to use less total R value just because you used spray foam, regardless of that spray foam being closed cell. Some spray foam installers claim that since spray foam air seals so well, it acts like more R value than it is. While better air sealing is a good thing, it doesn’t change the R value of the insulation. You should be air sealing when installing “regular” insulation too anyway.

BTW, your table shows you need R38 in the ceiling for climate zone 5, which you said you’re in. That is about 6.5 inches of closed cell spray foam if you use more realistic aged R values for the spray foam material. I would try for 7 inches or a little more though, to make sure that you don’t have any excessively thin spots in the valleys. I’d also use a piece of coat hanger wire to probe the foam in random places before the installers leave to make sure you don’t have any thin spots.

Bill

Thanks Bill. That is what I believe as well. I'll keep an eye on my email and see if the contractor in question ever replies. I have a feeling that they won't; or won't have a valid ref. to point me to in the code.

I may have miss quoted the R-30 value over the R-38 from the table (my bad). I am thinking of placing plastic markers under the deck to show depth in a few 'key spots' for ref. -- both mine and chosen vendor's.

PS. Vendor just responded that he's trying to find the ref. Maybe he'll send some internal, company marketing material. :)

He won't be able to find a reference in the code, because it was never in the code. The "spray foam needs less R value" falacy came out in some spray foam industry marketing materials years ago, and was never incorporated into any building codes.

Regarding continuous insulation, such insulation would have to be an unbroken sheet, such as rigid foam over the top of the sheathing. Spray foam on the underside of the sheathing will be broken by the studs, and those studs are thermal bridges, so that spray foam "layer" is not a contiguous sheet and thus is not continuous insulation for the purposes of the code. I don't see how the 'performance ' part of the code would apply here, either, for the same reason.

The simple reality is that spray foam installed between framing members, be those framing members rafters or studs, is just cavity insulation the same as anything else (batts, etc.). It has a bit better R per inch compared to most cavity insulation materials is all, and it does insulating and air sealing in one step, where with batts air sealing is a seperate step. That's it. Nothing magic.

Bill

Thorough explanation. Thanks Bill!

For walls, the code allows for a lower R-value for continuous insulation than for insulation between the studs, due to the reduction in thermal bridging. Only problem is that spray foam on the underside of a roof isn't continuous, and roofs aren't walls.

True.

I don't think it's just for walls. Roof too, or it can even be 'whole house' u factor I beleive.

Hi Tyler,

Pretty sure you are correct; check out "Table R402.1.4 Equivalent U-Factors" :

https://codes.iccsafe.org/s/iecc2018/chapter-4-re-residential-energy-efficiency/IECC2018-RE-Ch04-SecR402.1.4

That's from the 2018 IECC, so I'm not sure if/how it applies to IdahoBuild's situation, but it gives U-factor equivalents / alternatives to hitting R-values for walls, ceilings, etc etc

Not aware of what the foam contractor would be referencing, but there are 'performance' rather than 'prescriptive' paths. But that wouldn't jive with them just shooting out some random reduced r-value as they'd need to do some involved modeling for performance compliance.

Spray foam manufacturers did a "study" that showed that spray foam's air-sealing ability made it perform better than poorly-installed fiberglass insulation without an air barrier, and they used the results of the "study" to try to convince unsuspecting clients and code officials that lower R-values of spray foam should be acceptable. They no longer promote that idea, but they still practice shady marketing practices such as pushing the low global warming impact (GWP) of their newer formulations instead of the GWP of their products as a whole, and touting their "zero ozone-depleting potential" which only means they aren't breaking a law made as a result of the Montreal Protocol.

Makes sense....they'd need more info. (fenestration, wall u-/r-values) and engineered reports showing the total value for the building before throwing a blanket answer out for my project.

Possibly relevant to this discussion (if you haven't seen it already)--another Martin Holladay gem:

Another Deceptive Letter About Spray Foam R-Values

This time, the spotlight is on Lapolla

https://www.greenbuildingadvisor.com/article/another-deceptive-letter-spray-foam-r-values

Back in 2010, I wrote an article condemning certain deceptive sales practices by Icynene, a spray foam manufacturer. In that article, I discussed inaccuracies in a letter written and signed by Viktor Ginic, an engineer who was then employed by Icynene. Ginic wrote, “Based on measured air infiltration and the number of energy analyses performed, we have found that Icynene, installed in accordance with the manufacturer’s installation instructions to a nominal thickness of 3″ in the walls and floors and 6″ in roof/ceiling applications, will perform better thermally than R-19 and R-38 air-permeable mineral fiber insulation.”

...

Unfortunately, deceptive letters like the one distributed by Icynene are still being circulated by unscrupulous spray foam contractors. In late February, another example of these “Hall of Shame” letters was shared by a GBA reader named Russell Miller.

I think some of this has entered the realm of "honest mistakes" on the part of some installers. They've heard these claims themselves, so they repeat them without understanding they originated from somewhat shady "studies". Many times I find people repeat things they hear without verifying those things, and sometimes (maybe many times) also not stopping to think about "why" that claim might not be correct.

We are talking about physics here, and physics likes people to think logically if you want to make good decisions :-)

Bill

Bill, perhaps, but as an example, I once had a board member of the Spray Foam Alliance at my local BS + Beer and we basically argued for 90 minutes, and only one of us was using facts. (Hint: it wasn't him.) One quote from him, when discussing the same issue we're talking about here: "I don't know how to make other insulation airtight." That was his excuse for promoting the lower R-value issue.

I do respect Rick Duncan, director of the Spray Foam Alliance, who has answered my questions truthfully, and upon further review, accurately. I try to be fair when denigrating spray foam to not engage in misinformation; for example, it's true that the products of combustion between burning foam and wood are very similar, and the greatest risk of health impacts when installing foam are from inhaling the aerosols, not from the VOCs of off-gassing while curing.

Sounds like that other member you mention was a little heavy on the BS (the bad kind) and a little light on the beer :-)

I basically think it's important to be honest with materials and their respective pros and cons. This means not overstating their advantages (like the "our R value is better than theirs" stuff), and also not overstating (or downplaying) disadvantages (like the risk of spray foam fumes or botched installs). No one can make good decisions if they don't have accurate information after all.

My own pet peeve with spray foam is people who push it as a "whole home" option that is somehow "premium" compared to other insulating materials. I am not a fan of spray foam in walls, for example, since you can do just as well with mineral wool (or even fiberglass, if you're careful), you just need to do an old school air sealing job first.

Bill