Can I use Roxul’s new rigid board insulation above a roof deck in unvented attic without an air-impermeable insulation (foam)?

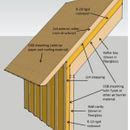

Attached is a sketchup pic of the assembly I am thinking about. I understand that IRC requires an air-impermeable insulation either above the roof deck (foam board) or below roof deck (spray foam). However, there is an exception for tile roofs in CZ 2B and 3B. Does this have more to do with the air that is able to circulate beneath the tile due to the profile and its install over straps? Or, is it more an issue of an arid climate? Could the assembly drawn be used in much wetter central NC (building codes not withstanding)?

This assembly could dry in both directions. The roofing material (likely asphalt shingles) has a large air gap between it and the exterior insulation. What am I missing? (I’m sure it’s obvious).

Thanks,

Harold

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Harold,

How to you keep those long "non-structural" 2x4 rafters from bending in the center under the snow load? Are you hoping that the mineral wool will be weight-bearing?

I was thinking that the 2x4's attached to the 1x4 strapping would resist deflection on their own to some extent (kind of 1/2 an I-beam). Yes I assumed (dangerous) that the mineral wool would be load bearing, but I see what you mean about snow load. The weight would only bear over the 1x4's and you're saying the mineral wool is not strong enough to support that kind of load without deflecting. Is there some amount of deflection in the mineral wool that would be acceptable?

Harold,

Don't ask that MW to bear any load. Use it as insulation rather than any form of structural element other than to carry the siding via during strips.Transfer the load through some framing lumber.

roxul seems to have significant compressive strength, no?

http://www.roxul.com/building+envelope/products/roxul+rockboard%C2%AE

perhaps re engineering the overhangs

I like the idea of all MW. I want to put R30 MW in the rafter bays and R24 MW batts over the roof deck and sheath again over that (using foam/flat 2x4 assemblies for nailers). Is the self-adhered membrane at the first deck enough to make it work or do I really need all-foam above? Thanks.

Harold,

Out of curiosity, why are you using rigid mineral wool for this application? If you use polyiso and make it a bit thicker (perhaps or 4" instead of 2") then you would probably not have to worry about dew-points for the interior roof decking in your climate. You can add 1x4 furring strips over the polyiso or second layer of OSB if you wanted a vent channel.

Rigid mineral wool has more embodied energy than polysio. Polyiso is great for warmer/cooling-dominated climates.

Just a thought...

Harold's post is from 2011, but I just made a comment before realizing. I made a new post I think. I see your point about the polyiso as far as embodied energy. I just was getting very frustrated wondering about the myriad issues with detailing foam (if it will shrink, if poly has a weird derating at certain temperatures, if the tapes stick, etc, etc). Wood fiber insul costs a ton, but I did look into that.

GBA readers: If you are interested in this Q&A thread, please post your comments on the other page where Shawn asked the same question. Here is the link: "Unvented cathedral ceiling with all mineral wool above and below."

"I understand that IRC requires an air-impermeable insulation either above the roof deck (foam board) or below roof deck (spray foam)"

Not really. When the insulation is above the roof deck the IRC does NOT require that the exterior R be vapor impermeable, only that it have sufficient R value for dew point control at the roof deck.

An OSB or plywood structural roof deck is already a Class-II vapor retarder, sufficient to protect a nailer deck on the top side of an unvented assembly. A layer of #30 felt between the structural roof deck and top side insulation lowers the vapor retardency even further when dry, but becomes more vapor open when moisture gets into the above-deck insualtion layer, allowing it to dry toward the interior. But venting above the top-side insulation is substantially more protective of the nailer deck than unvented.

With a vented nailer deck above the vapor permeable insulation it even offers an enhanced drying path for the structural deck, but the R-value still has to be sufficient for dew point control on interior side moisture drives.